Maintaining your snow clearing machine requires familiarity with its various components and how they function together. Proper knowledge of the system ensures smooth operation and helps with efficient repairs when needed.

Identifying the crucial elements of your machine can seem complex at first, but a clear understanding will allow you to troubleshoot problems and perform regular maintenance tasks effectively. Each part plays an important role in delivering optimal performance during winter operations.

By exploring a detailed reference guide, you can familiarize yourself with the placement and functionality of different components. This knowledge can prevent mishaps and extend the longevity of your equipment, making winter chores much easier and more manageable.

Understanding Your Snow Clearing Equipment Components

Getting familiar with the individual elements of your snow removal machine is essential for effective operation and care. Each piece has a specific function that contributes to the overall efficiency of the machine. Understanding how they interact can help you perform necessary maintenance tasks and troubleshoot problems when they arise.

The following list includes some of the key components you should be aware of:

- Engine: Powers the system and drives the motion of the machine.

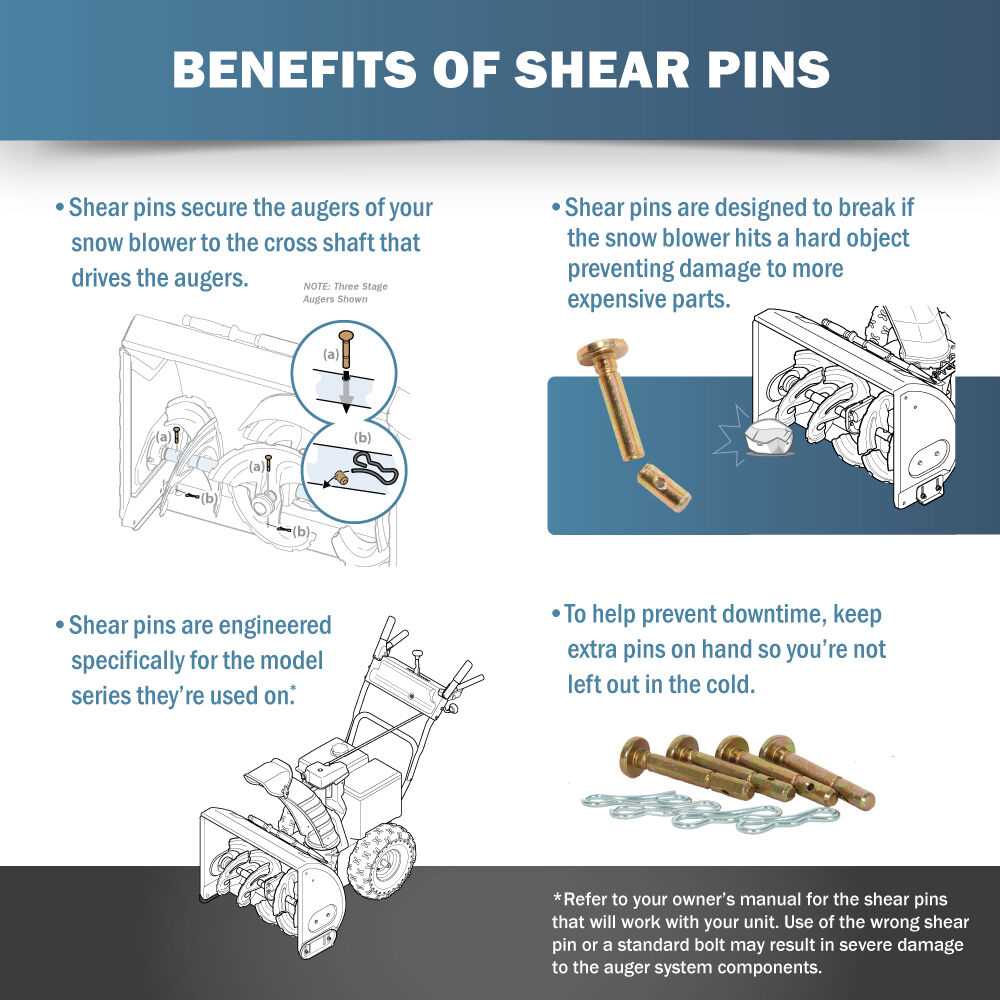

- Auger: Breaks up snow and ice, moving it toward the discharge chute.

- Chute: Directs the snow as it is thrown out of the machine.

- Drive Mechanism: Transmits power from the engine to the wheels, enabling movement.

- Controls: Allow for adjustments to speed, direction, and chute position.

Knowing these elements will help you identify areas that may need attention. For example, if the snow isn’t being cleared effectively, the auger or chute might require inspection. Regular upkeep of these parts ensures smooth functionality during cold months.

In addition to the main components, smaller parts like belts, pulleys, and switches also play an important role in the operation of the machine. Checking these elements regularly will help prevent issues and keep your equipment in top condition throughout the season.

Identifying Key Components of the Snow Removal Machine

To maintain optimal functionality, it’s essential to recognize and understand the primary elements that make up your equipment. Each component has a specific function, and knowing how they work together can help with routine checks, troubleshooting, and repairs.

Some of the most important parts to identify include the engine, which powers the system, and the auger, responsible for gathering and moving snow. The chute directs the discharged snow, while the drive system ensures smooth movement. Familiarity with these components can make maintenance and problem-solving more efficient.

Additionally, understanding smaller features like belts, pulleys, and control levers is crucial. These elements may seem less significant but play a major role in ensuring the machine operates smoothly. Recognizing potential issues early on can help extend the life of your equipment.

How to Use the Parts Reference Guide Effectively

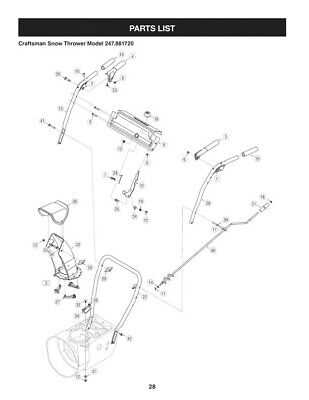

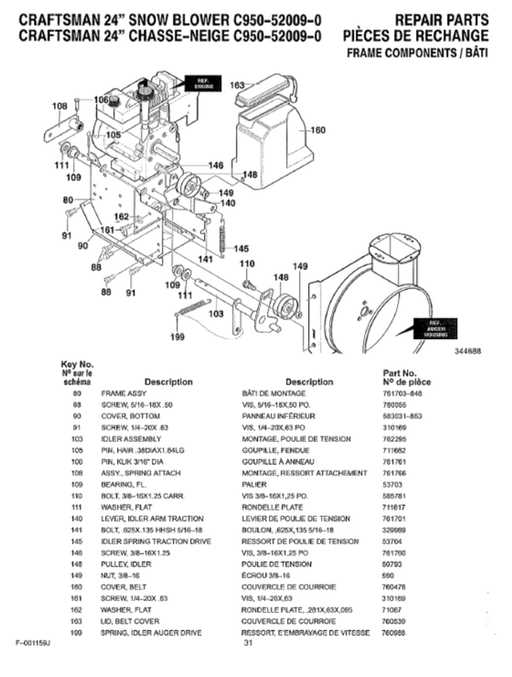

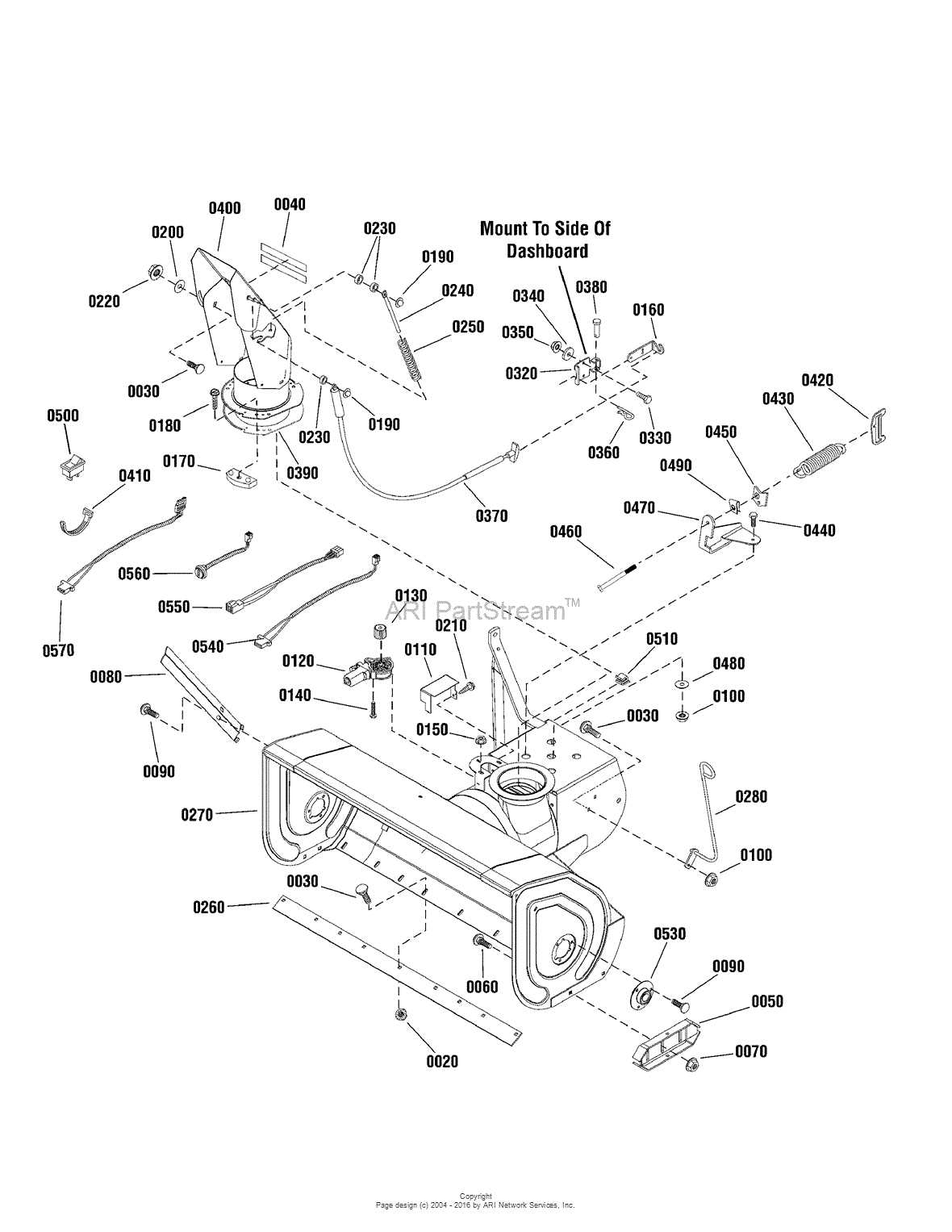

Using a reference guide for your equipment is a valuable tool when it comes to understanding the layout and function of individual components. The guide allows you to easily locate parts, identify their roles, and understand their relationship to other elements in the system. Knowing how to read and interpret this guide will save you time during repairs and maintenance tasks.

To use the guide effectively, start by locating the part you need to inspect or replace. The guide typically provides clear labeling, allowing you to match the physical part with the reference image. By following the visual cues, you can identify potential problems and understand how to address them without unnecessary guesswork.

It’s also helpful to refer to the part numbers or descriptions provided in the guide, as these can assist in purchasing the correct replacements. Make sure to cross-check the details with your equipment to ensure compatibility. Regularly referring to the guide during routine maintenance will help you maintain your machine in top condition throughout the season.