Understanding the inner workings of small engine machines can be crucial for anyone involved in maintenance or repair. The different sections and components that make up the power unit play a significant role in its performance and longevity. By having a clear visual reference, identifying parts and their functions becomes much simpler, allowing users to handle common issues with ease.

Proper knowledge of each element helps with troubleshooting and pinpointing any malfunctions. Being familiar with the overall structure of the engine ensures that, whether you’re a novice or an experienced technician, you can confidently proceed with any required repairs or upgrades.

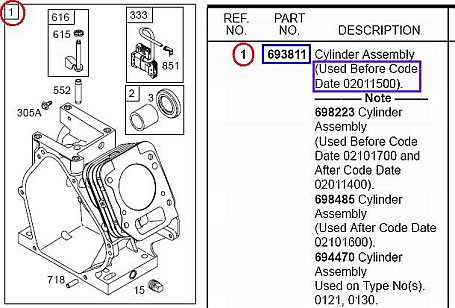

Having access to accurate schematics or illustrations of the engine’s layout provides an invaluable resource, making the repair process more efficient and reducing the likelihood of errors. These detailed drawings offer insight into where each part fits and interacts with others, enabling precise maintenance work without confusion.

Understanding the Engine Components

The internal structure of a small engine includes various elements that work together to create efficient operation. Each piece, whether it’s a moving part or a fixed component, plays a role in ensuring the machine runs smoothly. From the ignition system to the fuel delivery components, every section is designed to support the overall functionality of the engine.

Grasping how these parts interact with each other can make it easier to diagnose issues when performance declines. Common engine troubles often relate to wear and tear, misalignment, or improper assembly, making it essential to have a good understanding of each component’s role in the system.

Identifying these components and their functions provides a roadmap for maintenance and repair. By focusing on the key sections, users can troubleshoot effectively, ensuring minimal downtime and maximum performance from their equipment.

Key Components of the Engine

Every engine consists of several vital components, each with a specific function that ensures proper operation. Understanding these elements is essential for anyone looking to maintain or repair their equipment. From fuel intake systems to ignition mechanisms, every part plays a role in the performance and reliability of the machine.

Ignition System

The ignition system is a critical part that controls the starting process. It consists of several key elements, including the spark plug, ignition coil, and flywheel. These components work together to create a spark that ignites the fuel-air mixture inside the combustion chamber, starting the engine. Proper functioning of the ignition system is crucial for consistent engine performance.

Fuel Delivery Mechanism

The fuel delivery system ensures that the engine receives the correct amount of fuel at the right time. It includes components such as the carburetor or fuel injector, fuel pump, and fuel lines. A well-maintained fuel system allows for smooth engine operation and can prevent issues like stalling or inefficient fuel consumption.

Locating the Visual Reference Online

Finding accurate visual resources for small engine maintenance can make the repair process much more straightforward. These resources provide detailed illustrations of the engine’s structure, making it easier to identify specific components. With the right guide, anyone can quickly locate the parts they need to examine or replace, ensuring efficient troubleshooting.

Official Manufacturer Websites

Many manufacturers offer online catalogs or interactive guides for their products. These guides are typically available for free and provide a clear, detailed layout of all components, often with part numbers and descriptions. Visiting the official website is one of the most reliable ways to obtain the correct reference materials.

Third-Party Websites and Forums

In addition to official resources, third-party websites, forums, and communities often offer additional insights. These platforms may feature user-uploaded diagrams or links to external resources that can help find hard-to-locate components. Many enthusiasts and technicians share their expertise, offering valuable alternatives to official resources.

Where to Find Reliable Schematics

Accurate and trustworthy schematics are essential for anyone looking to repair or maintain small engine machinery. Finding reliable sources for these technical illustrations ensures that the right components are identified and the correct procedures are followed. Whether you’re a beginner or an experienced technician, using dependable resources is crucial for successful repairs.

Manufacturer’s Official Support Pages

The most reliable schematics often come directly from the engine manufacturer. These support pages provide official manuals and guides that feature detailed layouts of the engine’s components. Accessing the manufacturer’s website ensures that the diagrams are up-to-date and correspond precisely to the specific model you’re working with.

Online Repair Communities and Forums

In addition to official sources, online repair communities and forums can be valuable for finding trusted schematics. Enthusiasts and professionals often share high-quality images and links to useful resources. These communities can also provide insights and advice from others who have dealt with similar maintenance issues, adding practical experience to the theoretical diagrams.

Common Repairs for the Engine

Over time, engines can experience wear and tear, leading to common issues that require repair. Understanding the typical problems and knowing how to address them can save both time and money. Routine maintenance and fixing minor issues before they escalate can extend the life of the engine and improve overall performance.

Fuel System Maintenance

The fuel system is one of the most common areas requiring attention. Issues like clogged fuel lines or a malfunctioning carburetor can lead to poor engine performance or even prevent starting. Regular cleaning and inspection can prevent many of these problems.

- Replace fuel filters periodically.

- Inspect fuel lines for cracks or leaks.

- Clean the carburetor to ensure smooth fuel delivery.

Ignition System Troubleshooting

Problems with the ignition system are another frequent cause of engine malfunctions. A faulty spark plug or ignition coil can result in starting issues or inconsistent engine power. Replacing worn components can restore normal functionality.

- Check spark plugs for signs of wear or carbon buildup.

- Ensure the ignition coil is properly functioning.

- Verify the flywheel and magneto are aligned correctly.