Maintaining lawn equipment requires a solid understanding of its individual components. Each part plays a crucial role in ensuring smooth operation and durability. Having a clear idea of how each element fits together can simplify repairs and maintenance tasks.

In this guide, we will explore the essential components of a lawn care machine, offering insights into their functions and locations. Understanding how these elements interact is key to identifying issues and optimizing the performance of your equipment.

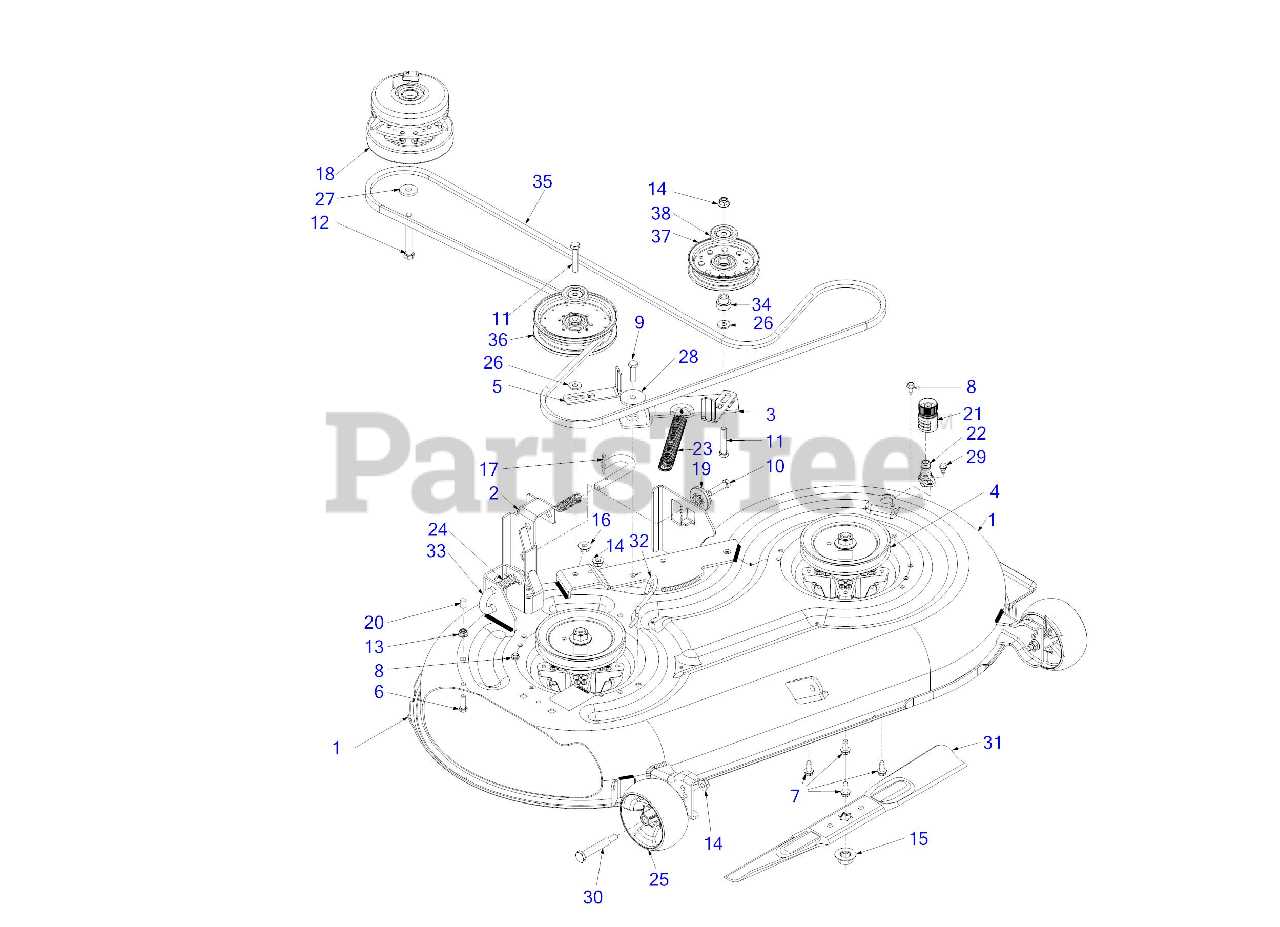

By referring to the component map, you can quickly locate specific areas that may need attention. This comprehensive visual reference helps in troubleshooting, part replacement, and general upkeep, ultimately extending the life of your device.

Understanding the Lawn Care Equipment

To keep your lawn equipment in optimal working condition, it’s essential to understand how its key components function together. Each section of the machine serves a specific purpose, contributing to its overall efficiency and performance. Familiarity with these elements will help in maintenance, troubleshooting, and repairs.

The primary function of this equipment is to efficiently manage the cutting process. Understanding the main areas, such as the drive system, blade assembly, and supporting structure, will provide clarity on how the system works as a whole. Each part works in harmony to ensure the equipment runs smoothly and delivers the best results.

By recognizing the different sections of the system, you’ll be better prepared to identify potential issues early. Regular inspection and maintenance will improve the longevity of the machine, making it an investment that continues to perform effectively over time.

Identifying Key Parts of the Lawn Equipment

Every machine is made up of several crucial components that allow it to function effectively. Understanding where each section is located and what it does will help you maintain and repair the device when necessary. Identifying these components is the first step in ensuring the equipment operates smoothly.

The cutting mechanism, for example, is one of the most important sections to focus on. This includes the blades and the associated drive system, which are essential for the device’s main task. Additionally, the support frame and wheel assembly provide stability and control during operation, allowing the machine to navigate various terrains.

Familiarizing yourself with the layout of these components will not only aid in repairs but also help you spot potential issues early. Proper maintenance of each part is vital to achieving the best results, keeping the machine running efficiently for a long time.

How to Use the Parts Diagram Effectively

Using a visual reference guide is an excellent way to locate specific components and understand how they fit together. This tool simplifies the repair process by clearly showing each section and its function. Knowing how to read and interpret this guide can save time and effort when fixing or replacing damaged components.

Follow these steps to make the most of the visual guide:

- Identify the key areas: Start by locating the main sections such as the cutting unit and drive mechanism. This gives you a clear idea of the machine’s layout.

- Check for specific parts: If you need to replace or inspect a particular component, locate it on the guide first to understand its placement and connections.

- Follow assembly instructions: Use the guide to ensure that parts are assembled or reassembled in the correct order and orientation.

By understanding the layout, you’ll be able to identify any malfunctioning parts or areas needing attention more effectively. A clear reference ensures you don’t miss any crucial steps, improving maintenance and repair efficiency.