When it comes to maintaining your outdoor power equipment, understanding its inner workings is essential. A clear illustration of all the key elements can make a world of difference when diagnosing issues or performing repairs. Knowing the specific parts of your tool allows you to work more efficiently and prolong its lifespan.

Whether you’re dealing with minor repairs or looking to replace a worn-out piece, a visual reference can save time and effort. Identifying and understanding each part can help you avoid mistakes and ensure that your equipment runs smoothly. This guide will provide you with a detailed overview of the crucial components, their functions, and how to handle them properly.

Accurate identification of the different sections in your tool is critical for effective maintenance. This resource will break down each part, explain its role, and show you how to handle common repairs and adjustments.

Understanding the Stihl MS 211 Diagram

For anyone who works with chainsaws, having a clear visual representation of its components is invaluable. A detailed illustration helps users understand how various parts fit together, making repairs, maintenance, and troubleshooting more efficient. This guide will explain the importance of understanding the layout and functionality of the key elements in your tool.

Key Benefits of a Visual Breakdown

One of the primary advantages of a well-structured illustration is that it simplifies complex machinery. By clearly showing each part and its connections, you can easily identify problems, make necessary adjustments, or replace damaged elements. It also aids in preventative maintenance by helping you spot early signs of wear or damage before they become serious issues.

How to Read and Interpret the Layout

To fully benefit from the visual guide, it’s essential to understand how the components are depicted. Follow these tips to interpret the diagram effectively:

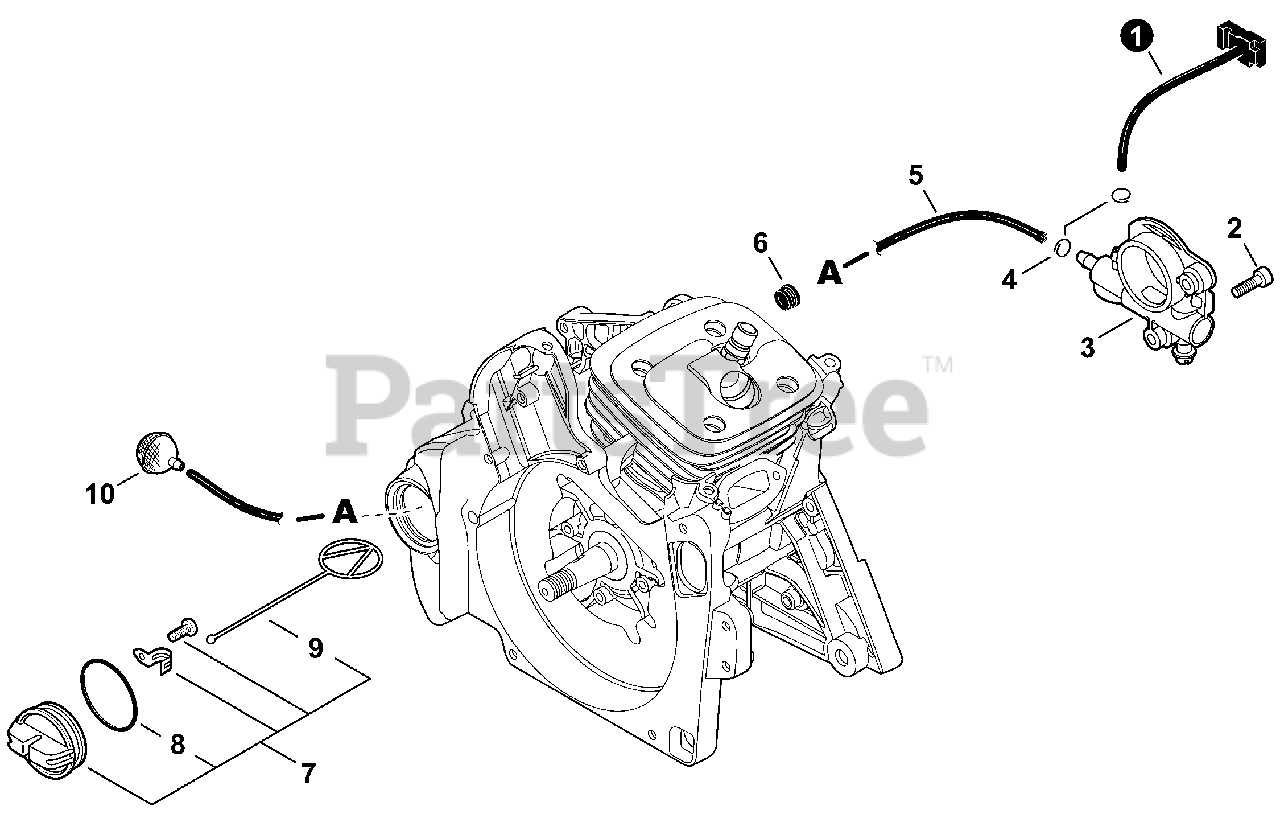

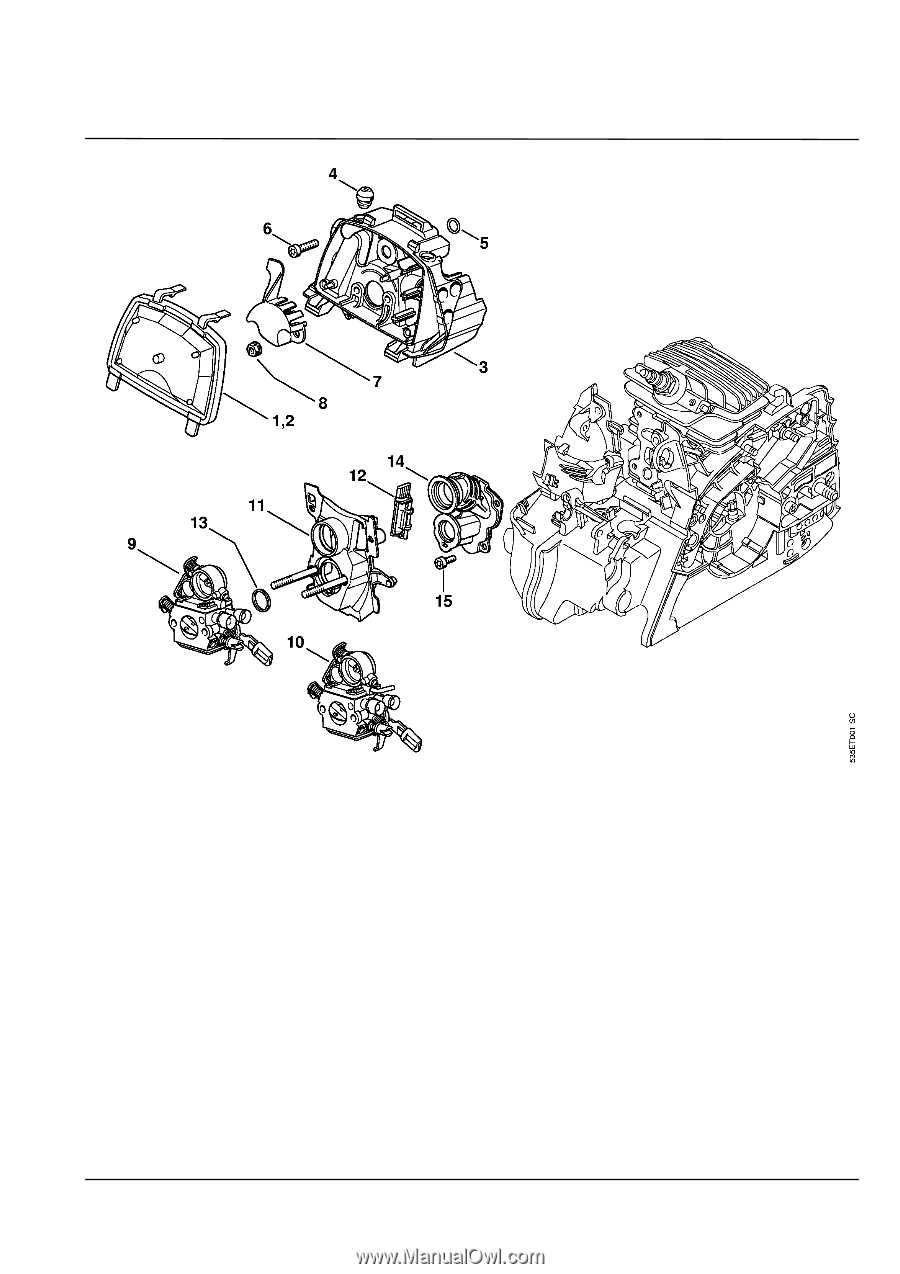

- Look for the main assembly and its major parts, such as the engine, carburetor, and air filter.

- Pay attention to the smaller components and their relationships to larger sections.

- Note the numbering or labeling of each part, which corresponds to the tool’s manual for easier identification.

- Focus on the arrows or lines that indicate the movement and interaction between parts.

By becoming familiar with the overall structure, you’ll be able to diagnose issues quickly, select the right replacement parts, and perform maintenance tasks with confidence.

Key Components of the Stihl MS 211 Chainsaw

Understanding the essential elements of your chainsaw is crucial for both routine maintenance and efficient repairs. Each component plays a significant role in the overall performance and longevity of the tool. Familiarizing yourself with these parts will enable you to address issues quickly and ensure your equipment runs at its best.

The main sections of a chainsaw include the engine, fuel system, cutting mechanism, and safety features. These parts work in harmony to provide the power and functionality needed for effective use. Below is a breakdown of the key components you should know about:

- Engine: The heart of the chainsaw, providing the power needed to operate the tool.

- Fuel System: Includes the carburetor, fuel filter, and fuel lines, which ensure the proper flow of fuel to the engine.

- Cutting Mechanism: Comprising the bar, chain, and sprocket, this system enables the saw to cut through various materials efficiently.

- Air Filtration: Helps maintain engine performance by preventing debris from entering the engine through the air intake.

- Starter Mechanism: Responsible for initiating the engine’s operation when the tool is first turned on.

By understanding how each part functions, you can ensure that all aspects of your chainsaw are in working order, leading to better performance and fewer breakdowns.

How to Use the Parts Diagram for Repairs

When it comes to repairing your tool, having a clear reference to its internal components can save time and prevent errors. A detailed schematic is a powerful tool that allows you to understand how each part is connected and functions within the system. Using this visual guide correctly can streamline your repair process and help you identify issues more accurately.

Step-by-Step Approach to Using the Visual Guide

To begin, identify the specific area of the tool that requires attention. Once you’ve located the section you need to repair, follow these steps:

- Locate the Component: Find the damaged or worn part on the visual reference. Pay attention to the labels or numbers next to each part for easier identification.

- Understand Its Function: Before removing or replacing any parts, ensure you understand its role within the system. This will prevent unnecessary disassembly.

- Check the Connections: Review how the part interacts with others and whether there are specific assembly instructions or patterns to follow.

- Replace with Correct Part: Once identified, replace the faulty component with a compatible one, ensuring it fits correctly in the specified location.

Common Repair Scenarios

Some common repairs that can benefit from a clear visual guide include:

- Reassembling the cutting mechanism after cleaning or maintenance.

- Replacing worn-out engine components like the carburetor or spark plug.

- Fixing issues with the fuel delivery system.

By carefully following the visual guide, you can avoid making mistakes, save time, and ensure the tool is functioning properly after repairs.