Every complex machine is made up of various interconnected elements that work together to ensure smooth performance. Familiarizing yourself with these individual components is crucial for proper maintenance and efficient troubleshooting. Whether you’re a professional or a hobbyist, knowing how each piece functions can save both time and money.

When examining a machine, it’s helpful to have a clear, visual representation of all the components. This allows you to easily identify where issues may arise and address them promptly. A well-documented reference can guide you through repairs and replacements, ensuring the equipment operates at its best.

In this guide, we will explore the essential aspects of understanding the key elements of your device. By the end, you’ll be equipped with the knowledge to tackle common issues, perform basic repairs, and maintain your equipment for optimal performance.

Understanding Predator 9000 Generator Parts

Each machine relies on a series of interconnected elements that allow it to function effectively. By understanding the key components and how they work together, you can identify and resolve issues more efficiently. This knowledge is essential for troubleshooting and maintaining reliable performance over time.

The core of any device lies in its individual sections, from the engine to the electrical components. Recognizing these parts and their functions will help you pinpoint the source of a problem, whether it’s related to power output, fuel delivery, or mechanical movement. In this section, we’ll take a closer look at these important components and explain their roles in the overall system.

Proper understanding also includes recognizing wear and tear indicators. Over time, certain elements may degrade, and knowing what to look for will allow you to replace or repair parts before they cause a failure. This proactive approach ensures the equipment runs smoothly and avoids costly repairs down the line.

How to Read the Parts Diagram

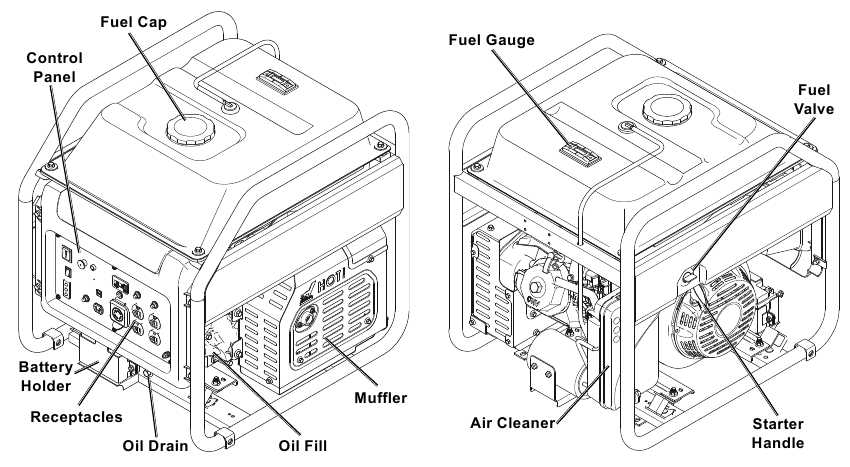

Understanding how to interpret visual references for a device’s internal structure is an essential skill for anyone maintaining or repairing equipment. These representations provide a clear, organized view of each component and its relationship to the others, helping users pinpoint issues and locate parts for replacement or repair. Mastering the reading of such resources can greatly simplify troubleshooting and maintenance tasks.

Familiarizing Yourself with the Layout

The first step in reading these visual guides is understanding how they are laid out. Typically, the components are arranged in a way that shows how they interact with one another. Here’s what you should focus on:

- Component Labels: Each section or element will usually be marked with a number or letter to identify it easily.

- Connection Points: Pay attention to how each part is connected to others, either through bolts, screws, or wiring.

- Orientation: Make sure you understand the perspective of the view, whether it’s a top-down or side view, as this can affect how you interpret the relationships between parts.

Steps to Use the Guide Effectively

Once you’re familiar with the layout, follow these steps to make the most of the reference:

- Start by identifying the part or component that you’re focusing on.

- Look at the reference number or letter associated with it.

- Locate the corresponding number or letter in the parts list for further details such as the part’s function or specifications.

- If you’re looking to replace a part, find the specific section in the manual or guide that lists compatible replacements.

By using these methods, you’ll be able to navigate the diagram with ease and effectively address any maintenance or repair tasks.

Common Issues and Repair Tips

Every mechanical system can experience certain common problems over time. Understanding these issues and how to fix them can save time, effort, and money. This section highlights some of the most frequent challenges users encounter and offers helpful solutions to address them.

Power Output Problems

One of the most common issues users face is insufficient power output. This can stem from several sources, such as fuel delivery problems or worn-out components. Here are some tips to resolve this issue:

- Check Fuel Levels: Ensure the fuel tank is full and that there is no contamination in the fuel.

- Inspect the Fuel Filter: A clogged filter can restrict fuel flow, leading to power loss. Replacing it is a quick fix.

- Examine the Spark Plug: A damaged or worn spark plug can prevent the engine from starting properly, affecting power. Replacing it may restore functionality.

Mechanical Failures and Noisy Operation

Another common issue is mechanical failure or unusual noise during operation. This often occurs due to worn-out moving parts or improper lubrication. Here’s what you can do:

- Lubricate Moving Parts: Ensure all moving elements, such as bearings and shafts, are properly lubricated to prevent friction and wear.

- Check for Loose Bolts: Tighten any loose bolts or fasteners to reduce vibrations that may cause noise or lead to further damage.

- Inspect the Oil Level: Low oil levels can cause overheating and mechanical damage. Regularly check and top up oil as needed.

By staying on top of these common issues and performing regular maintenance, you can extend the life of your equipment and prevent costly repairs in the future.