Proper maintenance and repair of outdoor equipment require a solid understanding of its individual components. Identifying each part is essential for troubleshooting, performing repairs, and ensuring the longevity of your machine. Whether you are dealing with wear and tear or performing regular checks, knowing how the parts fit together makes a significant difference in the overall performance.

Understanding the function of each piece allows you to make informed decisions during repairs and replacements. Being familiar with the structure also helps to spot potential issues before they become major problems. Keeping your tool in optimal condition depends largely on your ability to recognize and address specific needs of each component.

In this guide, we’ll explore how to break down your tool and its individual components. From identifying essential parts to offering useful tips on keeping everything running smoothly, this information will help you enhance the efficiency and lifespan of your equipment.

Understanding the Stihl BG65 Components

Every outdoor tool is made up of a series of interconnected elements that work together to ensure its functionality. Understanding these individual elements is crucial for effective maintenance and repair. When each part is operating correctly, the entire system performs at its best, allowing the user to get the most out of their equipment.

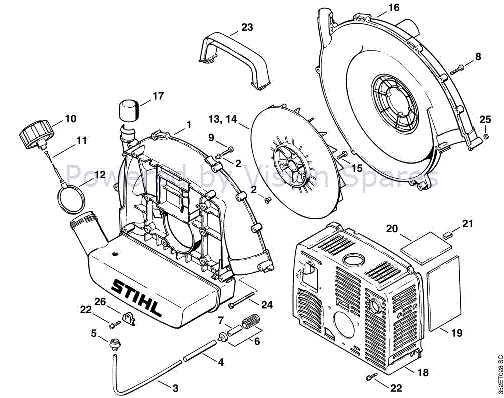

Each component serves a specific function, whether it’s powering the motor, directing airflow, or maintaining overall structural integrity. Recognizing how these pieces interact helps prevent damage, as well as improve performance. For example, knowing the role of the fuel system, air intake, or exhaust components can guide troubleshooting efforts and help you avoid costly repairs.

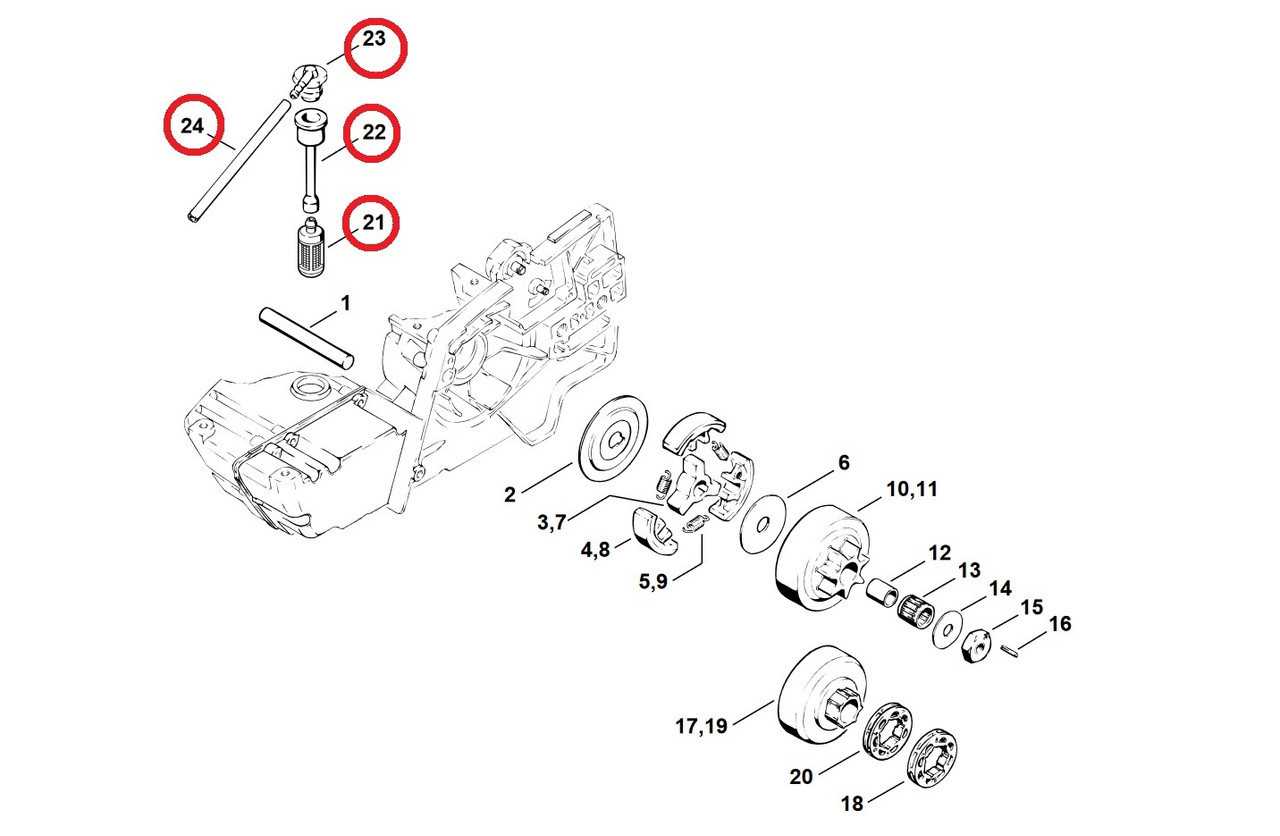

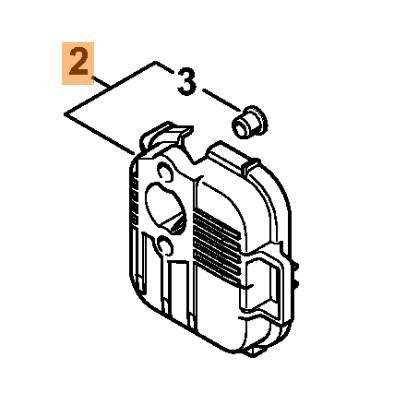

Being able to identify the various parts of the tool is the first step in understanding its workings. Familiarity with the internal and external components not only makes maintenance easier but also helps with upgrading or replacing individual elements when necessary.

How to Identify Stihl BG65 Parts

Recognizing the individual components of your equipment is essential for both repairs and regular maintenance. Each part plays a specific role in ensuring the tool functions properly. By understanding how to identify these pieces, you can address issues more efficiently and prolong the lifespan of your device.

Visual inspection is the first step in identifying components. Begin by looking for identifying numbers or markings on the parts themselves, as these can often point to their function. Consulting the user manual or manufacturer’s guide can also be helpful, as they usually contain detailed information about each piece and how it should appear when in good condition.

In addition to visual clues, understanding how each element interacts with others is vital. For instance, recognizing the airflow path, fuel system connections, and exhaust flow can help pinpoint specific issues. Knowing what each part does will allow you to make informed decisions about replacements and repairs.

Tips for Maintaining Your Stihl BG65

Proper upkeep is key to ensuring the longevity and efficiency of your outdoor tool. Regular maintenance prevents wear and tear, reduces the need for costly repairs, and keeps your equipment running smoothly. By adopting a consistent care routine, you can avoid unexpected breakdowns and improve performance.

Cleaning your tool regularly is one of the simplest yet most effective ways to keep it in top shape. Dirt and debris can clog essential components, leading to overheating and decreased efficiency. Make sure to clean both the exterior and internal areas, especially air vents and filters, to ensure proper airflow and operation.

It’s also important to check and replace wearable parts like fuel filters, spark plugs, and air filters. These elements can degrade over time and impact the performance of your tool. Keeping an eye on these components and replacing them when needed will help avoid unnecessary stress on the motor and extend the tool’s lifespan.