When working with equipment designed to support and elevate heavy loads, it’s essential to understand the various components that make up these systems. These elements work together to provide stability, strength, and functionality during use. Familiarizing yourself with each part ensures proper maintenance, troubleshooting, and effective operation.

The intricate design of lifting devices requires a clear understanding of how each element interacts within the system. This knowledge helps to identify wear and tear, replace damaged components, and ensure the equipment remains functional for longer periods. Whether for repairs or upgrades, knowing the structure and function of the system is crucial.

In this guide, we will break down the key components involved in these lifting mechanisms, offering a detailed look at their functions and importance. This will help you recognize issues, enhance your understanding of the system, and improve overall performance.

Key Components of a Lifting Mechanism

Understanding the core elements of lifting systems is essential for their proper use and maintenance. These essential components work together to ensure stability, movement, and reliability when elevating heavy objects. Each part plays a distinct role in the operation, contributing to the system’s overall effectiveness.

Among the most critical components are the lifting column, base, and handle. The column provides the necessary height adjustment, while the base offers support and balance. The handle is designed for manual control, allowing easy manipulation of the system’s height. Other key elements include locking mechanisms that ensure safety and prevent unintended movement when in use.

In addition to these primary elements, additional accessories like wheels or mounting brackets help increase mobility and secure the lifting system during operation. Each component is vital to maintaining the safety, functionality, and durability of the equipment, requiring regular inspection and timely replacement when needed.

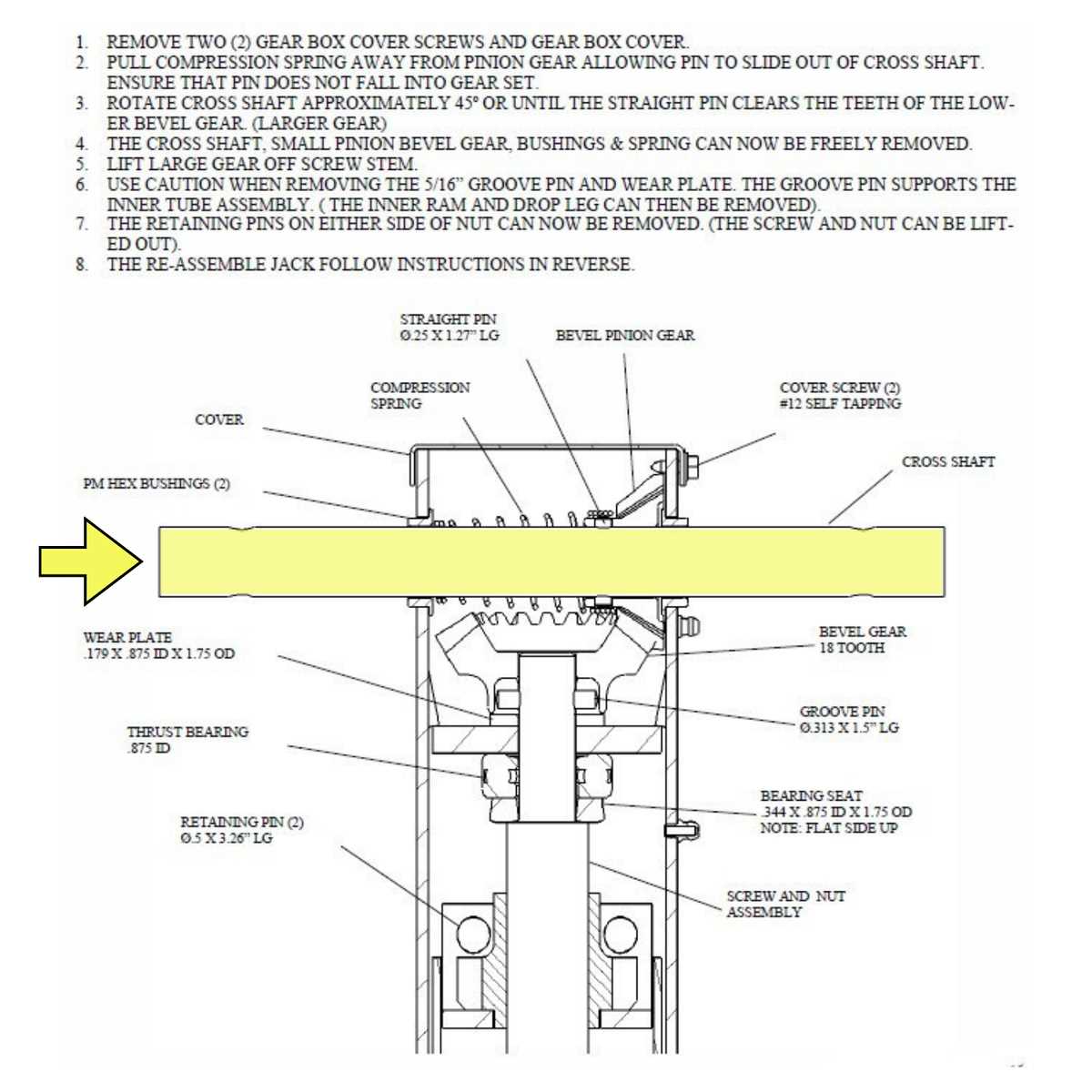

How to Read a Lifting System Blueprint

Understanding the blueprint of a lifting system requires an organized approach to interpreting the layout and symbols used to represent various components. These schematics are designed to provide a visual guide to each part’s location, function, and relationship within the overall structure. By familiarizing yourself with the diagram, you can easily identify how the system operates and troubleshoot any issues effectively.

The blueprint typically includes labeled components, with lines and symbols indicating connections and movements. Each part will be numbered or marked, often with a reference to a specific part list or manual. These references help you identify which components correspond to the visual representation on the diagram. Pay close attention to the orientation and placement of elements, as these details are crucial for assembly and maintenance.

To read the diagram effectively, start by identifying the key parts, such as the base, lifting mechanism, and any safety features. Follow the lines to understand how the parts connect and interact with one another. This step-by-step process will help you gain a clear understanding of how the system works and assist in troubleshooting or repairing the equipment.

Common Issues with Lifting System Components

While lifting systems are built to withstand heavy use, several issues can arise over time. These problems often stem from wear and tear, improper maintenance, or external factors affecting the equipment’s performance. Understanding these common issues will help you identify and resolve them quickly, ensuring safe and efficient operation.

Damaged or Worn-out Components

One of the most frequent problems is the deterioration of key components such as the lifting column or the locking mechanism. Regular use can cause parts to wear down, leading to reduced functionality or even failure. It’s essential to inspect these elements for signs of damage, such as cracks, rust, or bent parts, and replace them as needed to maintain performance.

Issues with Movement and Adjustment

Another common issue is difficulty in movement or height adjustment. This can be caused by issues like dirt or debris accumulation in moving parts, or by a malfunctioning mechanism that prevents smooth operation. Lubrication and cleaning are key to resolving this issue, as well as checking for any obstructions or faulty parts that may need replacement.