Maintaining a lawn trimmer can be a straightforward task when you have a clear understanding of its essential components. Knowing where each part fits and how they function together is crucial for proper operation and easy troubleshooting. Whether you’re replacing a damaged part or performing regular maintenance, a clear overview of the internal and external components is invaluable.

When working with these devices, having a guide that maps out the connections and arrangements of key parts can save time and effort. It helps identify which components are responsible for specific tasks and how to replace or repair them effectively. Understanding the parts structure not only ensures better performance but also prevents unnecessary damage caused by improper handling or repairs.

By familiarizing yourself with the internal workings of these tools, you can improve their lifespan, reduce repair costs, and enjoy smoother operation with every use. A visual reference can make the entire process easier, giving you the confidence to tackle any maintenance task with ease.

Understanding Trimmer Components

Proper knowledge of a lawn trimmer’s structure can greatly enhance its performance and ease of maintenance. Each component plays a critical role in ensuring the machine operates efficiently, and understanding how they interact with each other can prevent common issues. Whether you are dealing with engine troubles, line feed malfunctions, or handle adjustments, recognizing the essential parts will guide you through any repair or replacement task.

Key Components and Their Functions

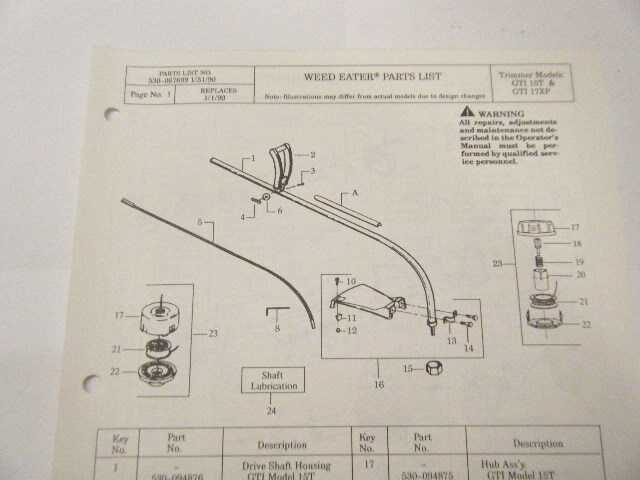

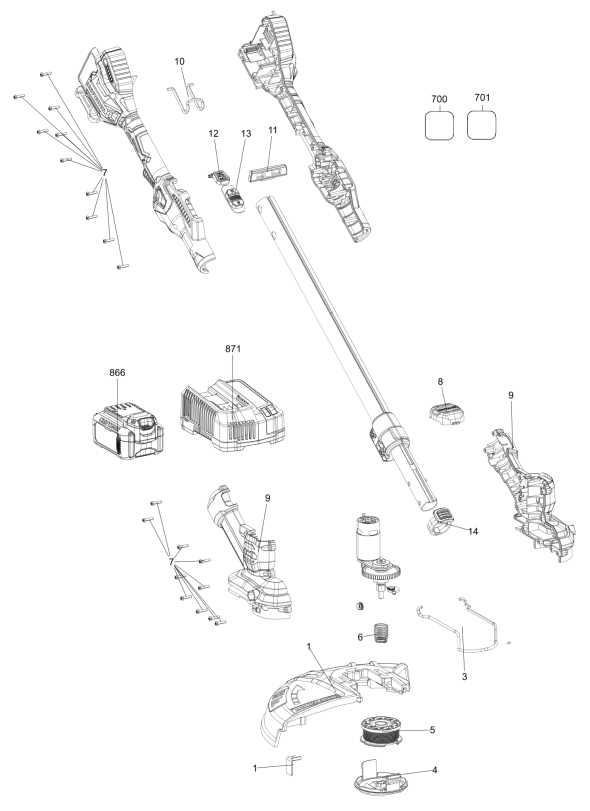

The trimmer’s motor is the heart of the device, providing the power needed for cutting. The shaft transmits this power to the head, where the cutting mechanism is located. Other vital components include the handle, which offers control and comfort, and the guard that protects you from flying debris. Each part is designed to work in harmony to give the tool its full cutting potential, making it crucial to maintain these elements regularly.

Common Issues and Troubleshooting

When facing issues with the trimmer, understanding the function of each component can help pinpoint the problem more efficiently. For example, if the cutting head isn’t rotating properly, it could be due to a malfunction in the drive system or a worn-out motor. Similarly, a malfunctioning line feed can be caused by improper alignment or damage to the spool. Being aware of these potential issues ensures faster troubleshooting and helps prevent further damage to the equipment.

Identifying Key Components for Repairs

When troubleshooting a lawn trimming tool, identifying the correct components is essential for effective repairs. Each mechanism within the device serves a specific function, and understanding their roles can help quickly determine which part needs attention. Recognizing the most common parts that experience wear and tear will allow you to address issues more efficiently and reduce downtime.

Common Components to Check

The motor is the primary source of power, and if the device fails to start, it may be the first component to inspect. Next, the cutting head and spool, which handle the trimming action, often require maintenance due to frequent use. If the head isn’t spinning or the line isn’t feeding properly, these parts may be damaged or clogged. Lastly, ensure the safety guard and handle are intact and securely fastened to maintain safe operation.

Steps for Diagnosing Issues

Start by inspecting the exterior for any visible damage or loose connections. Check the line spool for any tangled or broken lines, and examine the cutting head for any signs of wear. If the motor is not working, test the power switch and connections to ensure electrical continuity. By systematically examining each component, you can pinpoint the issue and determine the necessary repairs or replacements with minimal effort.

Common Issues and Fixes for Lawn Trimmers

Even with proper maintenance, lawn trimming tools may face occasional problems that affect their performance. These issues can range from power failures to difficulties with the cutting mechanism. Understanding the most common problems and their solutions can help restore your tool’s functionality quickly and effectively.

Power Problems and Solutions

One of the most frequent issues is a failure to start or intermittent power. This may be caused by a faulty motor, a clogged air filter, or issues with the spark plug. Start by checking the electrical connections and cleaning any debris from the filter. If the spark plug appears worn, replace it. A well-maintained motor is essential for smooth operation, so regular cleaning and inspection are key to preventing power issues.

Cutting Head and Line Feeding Issues

If the cutting head isn’t spinning properly, it might be due to a worn-out drive belt or an obstruction in the mechanism. Inspect the area around the head for debris or damage that could be causing the malfunction. The line may also fail to feed correctly if the spool is tangled or improperly aligned. Make sure the spool is correctly wound and replace any damaged lines. For smoother operation, clean the feeding system to ensure no blockages are present.