Knowing the different elements of your archery equipment is essential for proper maintenance and efficient use. Every tool, mechanism, and accessory plays a crucial role in ensuring performance and reliability. Familiarizing yourself with these components will enhance your experience, whether you’re a beginner or an experienced archer.

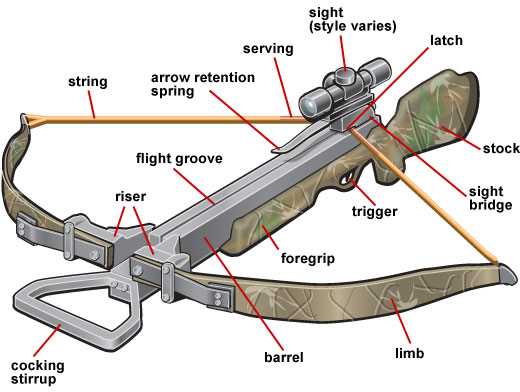

Having a clear visual representation of the different sections and how they interact with each other can be incredibly helpful. It allows for better understanding when performing routine checks, troubleshooting, or upgrading specific parts. Identifying each piece and its function helps avoid unnecessary confusion during repairs or adjustments.

Maintaining your equipment in good condition requires an understanding of how each part contributes to the overall function. Regular inspections and knowledge of the components will ensure you get the best performance out of your gear, extending its lifespan and improving accuracy.

Understanding the Archery Gear Components

Every piece of an archery weapon plays a vital role in its overall functionality. From the primary structure to the smallest accessories, each element contributes to the equipment’s performance. It’s essential to recognize how these components interact to ensure smooth operation and precision.

Some components provide structural stability, while others enhance the accuracy and power of each shot. For instance, the main assembly is designed to withstand the force exerted during use, and the tension mechanism ensures that each shot is consistent and powerful. Understanding these functions helps you identify potential issues and improve the efficiency of your gear.

By familiarizing yourself with each section, you can perform better care and maintenance. Whether it’s the string system, the safety features, or the trigger mechanism, knowing how everything fits together will aid in troubleshooting problems and improving overall handling.

How to Identify Archery Equipment Components Accurately

Recognizing each element of your equipment is crucial for effective maintenance and troubleshooting. Accurate identification allows you to assess the condition of individual components and ensures you make the right adjustments when necessary. Understanding the function of each section is key to this process.

Visual Inspection Techniques

The first step in identifying components is conducting a thorough visual inspection. Start by examining the main body for any visible damage or wear. Pay close attention to key areas such as the tension mechanism, trigger system, and structural supports. Knowing what each part looks like will help you quickly spot any issues and determine if replacement or repair is needed.

Using Reference Guides

Utilizing reference materials, such as manuals or online resources, can be incredibly helpful in identifying specific sections. These guides provide detailed images and descriptions, making it easier to correlate what you see with the correct terminology. Having a visual reference ensures you don’t miss anything important and helps you avoid confusion.

Maintenance Tips for Archery Gear Components

Proper upkeep of your archery equipment ensures longevity and peak performance. Regular maintenance prevents wear and tear, extends the life of key sections, and enhances accuracy. Taking a proactive approach to care will keep your gear in optimal condition and ready for use whenever needed.

Cleaning and Lubrication

Maintaining cleanliness is essential to avoid buildup that could interfere with the smooth operation of your gear. After each use, wipe down the surfaces to remove dirt and moisture. Lubricating the moving parts, such as the tension system and trigger mechanism, will ensure they operate without friction, providing more reliable performance. Use only recommended lubricants to avoid damage to the materials.

Regular Inspections and Adjustments

Performing routine checks on your equipment will help you spot issues before they become major problems. Check for any cracks or signs of fatigue in the structural components. Tighten any loose bolts or screws, and adjust the tension system as needed. Regular inspections help maintain optimal functionality and ensure all parts are securely fastened and in good working order.