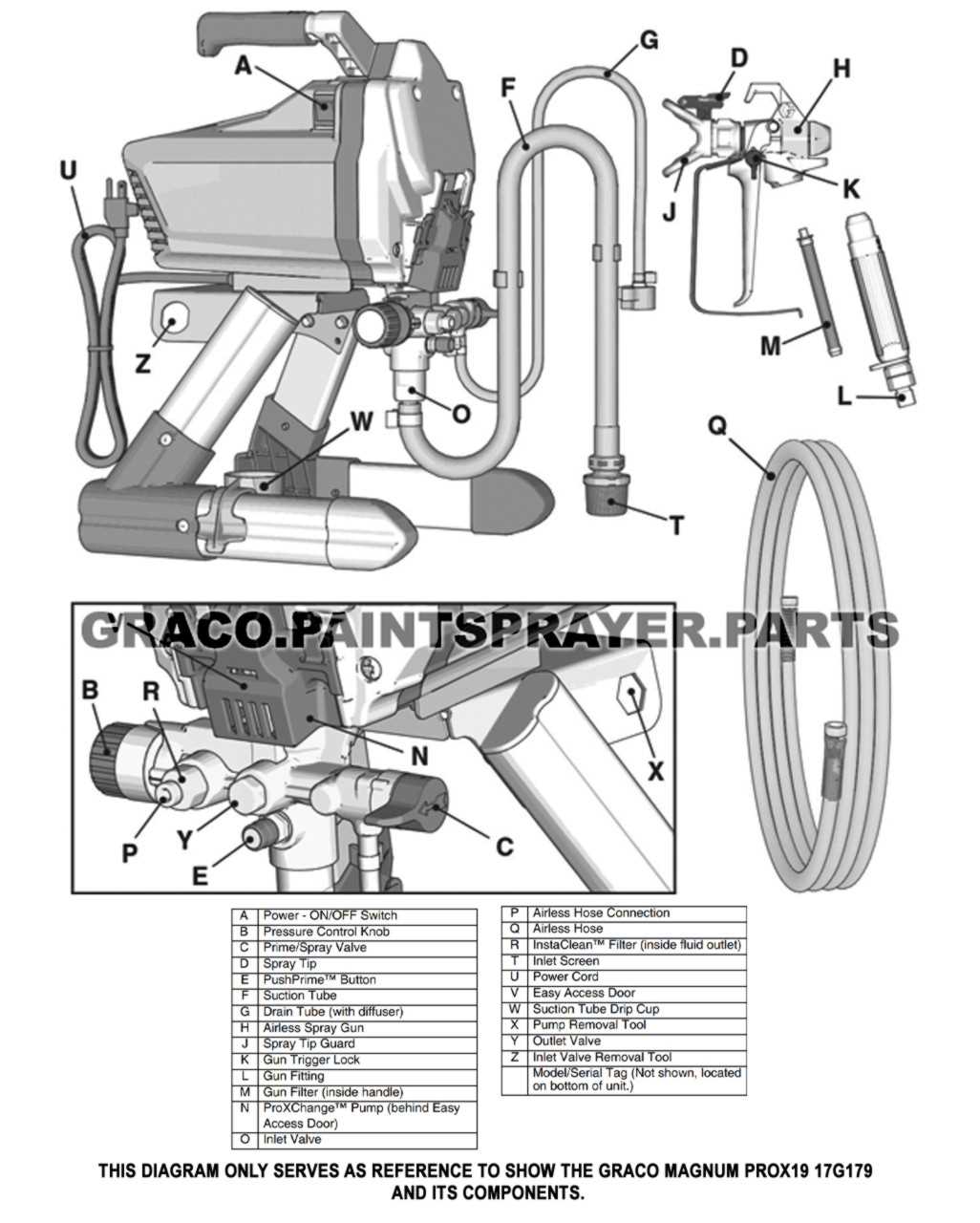

Understanding the inner workings of any mechanical device is essential for maintenance and efficient operation. A well-organized illustration can help users identify each element of the system and its role. This is particularly useful when repairs or replacements are necessary, allowing users to make informed decisions about their equipment.

In this guide, we will explore how to effectively navigate the schematic representation of key components and assembly structures. Whether you are a professional or a DIY enthusiast, having a clear reference point for understanding your equipment can significantly enhance your troubleshooting process.

By breaking down the components into manageable sections, the visual representation serves as a valuable tool in identifying parts and their connections. With the right knowledge, performing maintenance tasks becomes a more straightforward and less intimidating process.

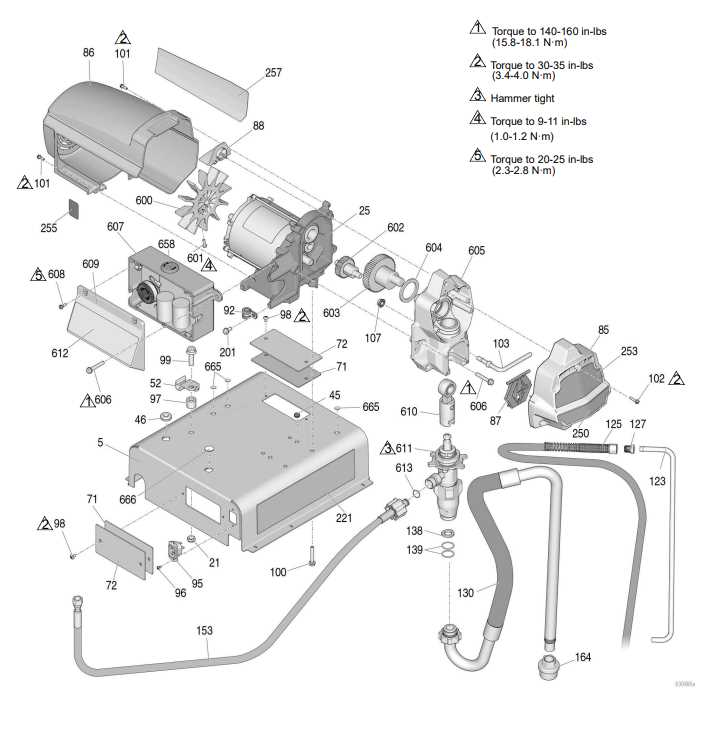

Understanding the Equipment Breakdown Illustration

When dealing with complex machinery, having a clear visual guide to its components is crucial for effective maintenance and repair. Such a schematic provides a detailed view of how different elements interact, helping users quickly identify and understand each part’s function within the system. This visual representation not only aids in recognizing potential issues but also allows for a more streamlined approach to repairs and replacements.

By examining this visual guide, users can familiarize themselves with the layout of the equipment. Each component is typically labeled with a corresponding number or description, making it easy to locate and verify specific parts. This method is especially helpful when troubleshooting problems or ordering replacement items, as it eliminates confusion about which part needs attention.

Proper understanding of the equipment’s internal structure enables users to perform more precise repairs, ensuring that each part is correctly handled. Whether it’s for routine maintenance or a more involved fix, having a well-organized reference is an indispensable tool for anyone working with mechanical systems.

Key Components of the Equipment

Each machine consists of several critical elements that work together to ensure smooth operation. Identifying and understanding these parts is vital for both performance optimization and troubleshooting. From the core assembly to the smallest supporting elements, each component plays a specific role in the overall functionality of the system.

Main Assembly

The main assembly houses the core structure of the system, including the motor and primary drive mechanisms. This central unit is where most of the power and control systems are located, allowing the equipment to function as intended. Proper maintenance of this area ensures long-lasting efficiency and reduces the risk of major failures.

Supporting Components

In addition to the primary structure, the supporting components include various smaller parts that enable smooth operation. These include connectors, seals, and safety valves, which ensure that the machine operates efficiently and safely. Regular inspection of these components is necessary to prevent wear and tear that could lead to operational issues.

How to Use the Visual Guide Effectively

Understanding how to read and interpret a schematic can significantly improve your ability to diagnose and repair equipment. The visual guide serves as a map, outlining the entire system and its individual components. By becoming familiar with its layout, you can pinpoint issues more quickly and make the necessary adjustments without confusion.

To use the guide effectively, start by identifying the main sections of the system. Each area of the schematic typically corresponds to a specific function or part of the equipment. Once you know the general layout, you can focus on the smaller components that might require attention. It’s helpful to cross-reference the visual with the manual for part numbers and descriptions, ensuring you are dealing with the correct component.

Regularly reviewing the schematic will also help you become more proficient at identifying problems before they escalate. Over time, you’ll be able to recognize common wear patterns and anticipate which parts might need replacing. This proactive approach helps maintain optimal performance and extends the life of your equipment.