When working with precision tools, knowing the individual components and their functions is essential for proper usage and upkeep. Each tool consists of various elements that work together to deliver efficiency and performance. A comprehensive guide to these parts can simplify maintenance and repair tasks, ensuring your tool functions at its best.

Identifying each component and understanding how they interact allows you to troubleshoot issues more effectively. Whether replacing a worn-out part or performing routine checks, familiarity with the parts enhances the tool’s longevity and helps you avoid unnecessary replacements.

Exploring the inner workings of tools makes it easier to handle any challenges that arise. Gaining insight into their construction is the first step toward mastering their use, boosting both confidence and productivity. Comprehending the relationship between various components also minimizes the risk of damaging your equipment during maintenance.

Understanding the Tool Components

Each tool consists of several key elements, each contributing to the overall functionality and efficiency. A clear understanding of these components is crucial for effective use and maintenance. By identifying and recognizing each part, you can ensure the tool performs optimally and address any issues that may arise.

The tool is built from both internal and external components that work together seamlessly. Knowing the function of each element allows you to troubleshoot problems and make informed decisions when repairs or replacements are necessary.

- Motor – Powers the tool and drives its movements, providing the necessary energy for operation.

- Housing – Encloses and protects the internal components from damage, ensuring safe use.

- Switch – Allows for easy operation by turning the tool on and off.

- Chuck – Holds attachments securely in place, ensuring stability during use.

Familiarizing yourself with these key elements ensures that you can properly maintain your equipment. Whether you’re replacing an element or performing routine checks, knowing the tool’s inner workings helps extend its lifespan and avoid unnecessary breakdowns.

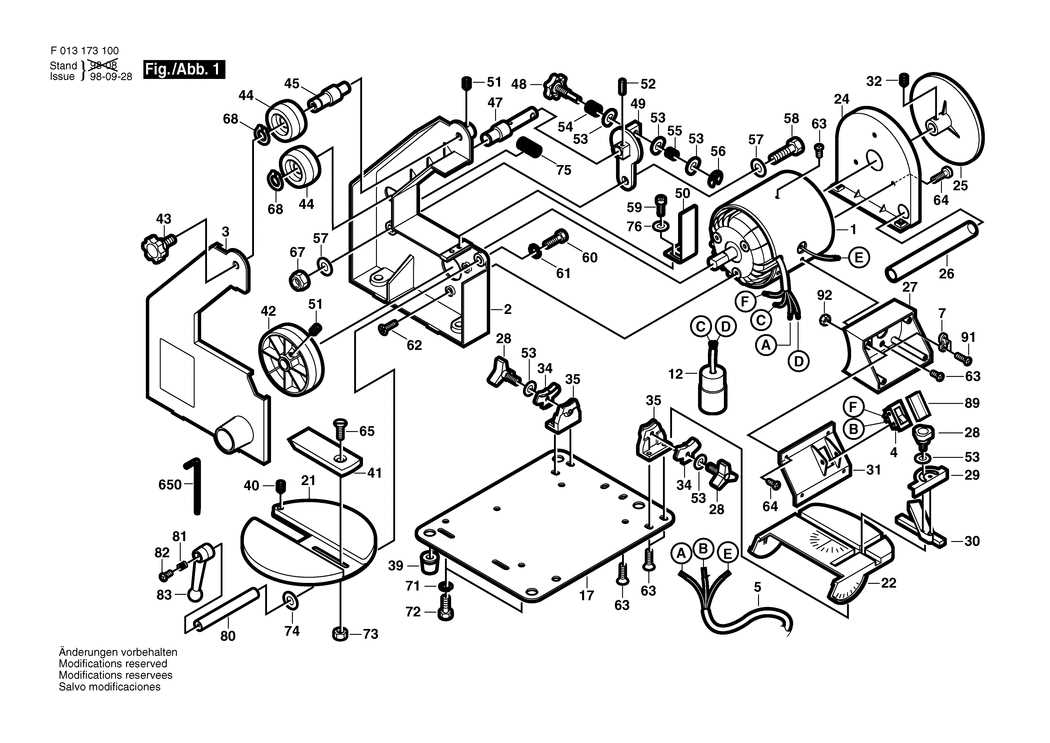

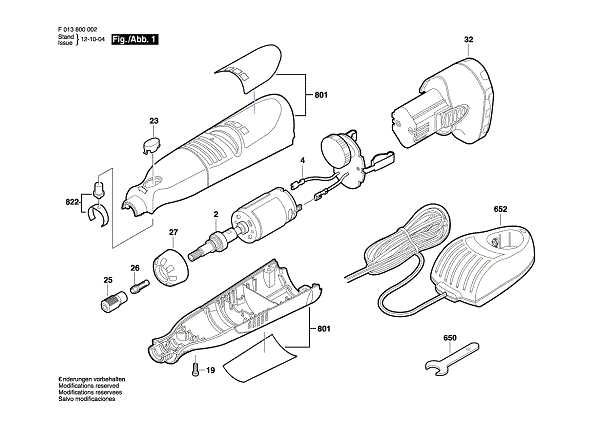

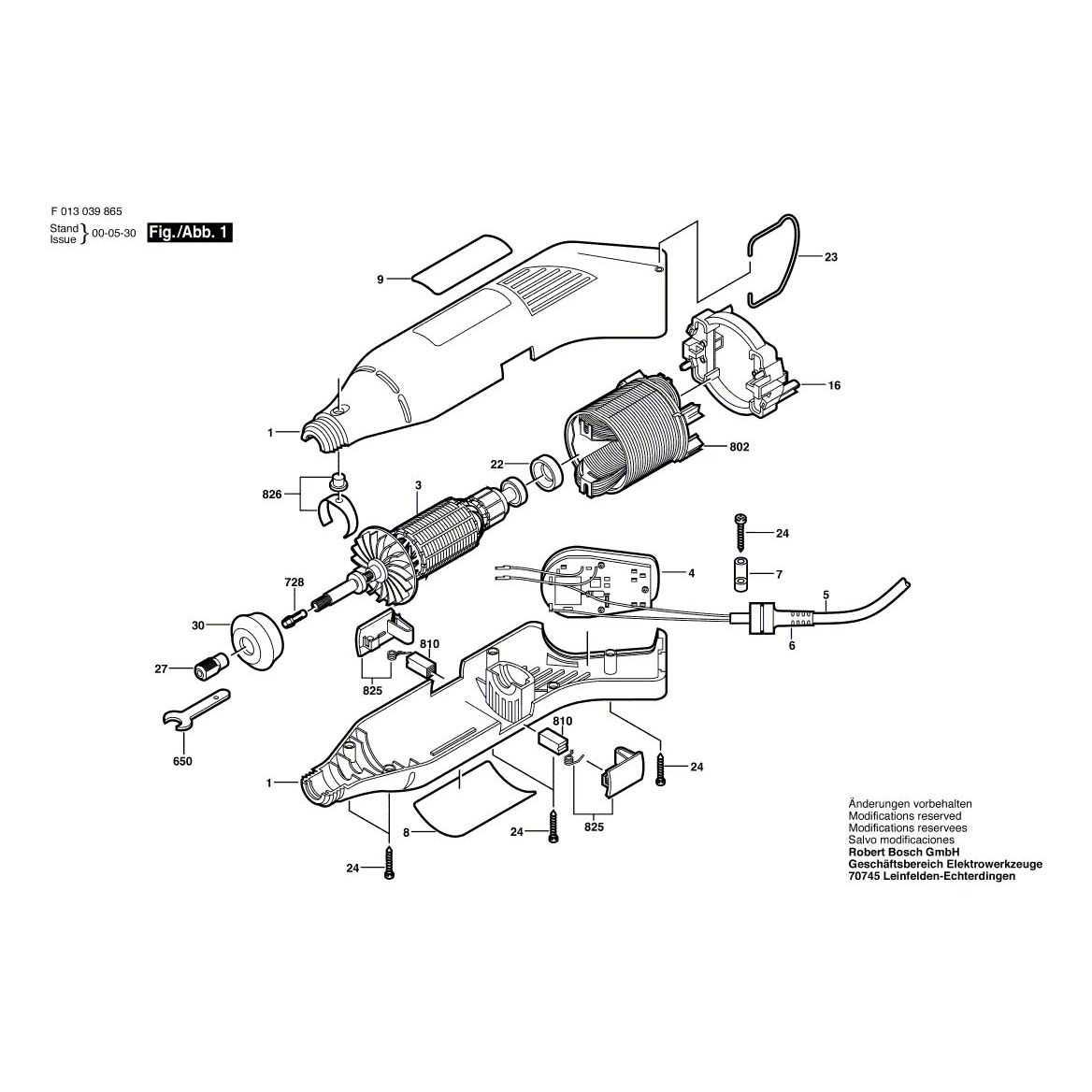

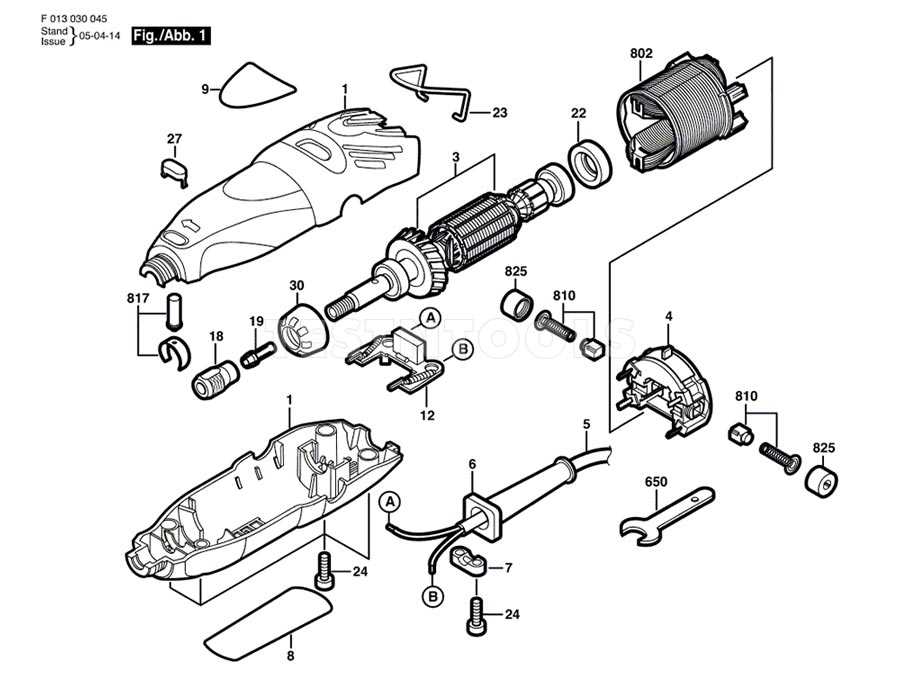

How to Read a Tool Component Breakdown

Understanding how to interpret a visual representation of a tool’s internal structure is essential for effective maintenance and repair. These illustrations serve as a helpful guide, showing each individual element and how they fit together to make the tool function properly. Learning how to read this representation can simplify identifying worn or damaged parts, making it easier to replace them with the correct components.

The key to successfully using such a visual is familiarity with the layout. Typically, the parts are labeled in a way that matches their real-world counterparts, often with numbers or letters next to each section. It’s important to carefully examine each segment and compare it with the corresponding labels to avoid confusion.

By understanding the layout and how the elements interact, you can more confidently tackle repair tasks. This knowledge helps reduce the risk of mistakes and ensures that each replacement part fits correctly, ultimately extending the tool’s life and improving its performance.

Common Tool Components and Their Functions

Every precision tool is made up of several key elements, each with a specific role in ensuring optimal performance. Understanding these components and their functions is essential for proper usage, maintenance, and repair. By recognizing these parts, you can easily identify when something isn’t working correctly and know which parts need attention or replacement.

Key Components

The following components are commonly found in many tools, and understanding their roles helps you maintain and troubleshoot effectively:

- Motor – Provides the power to drive the tool’s operation, converting electrical energy into mechanical movement.

- Switch – Controls the power flow, allowing users to turn the tool on and off.

- Chuck – Holds various attachments securely, ensuring they remain stable during operation.

- Housing – Protects the internal mechanisms from external damage, ensuring safety and durability.

Additional Components

Other elements, although not as frequently discussed, play significant roles in the overall functionality of a tool. These components include:

- Brushes – Assist in delivering current to the motor and help maintain its efficiency over time.

- Collet – A clamp that holds tools or accessories in place while working.

- Cooling System – Prevents the motor from overheating, ensuring smooth performance during extended use.

Each of these components is essential for the tool’s overall functionality. Understanding their roles can help you make informed decisions about maintenance and repairs, ensuring your tool operates at its best for a longer period.