In any mechanical tool, understanding the individual elements that work together is essential for proper use and maintenance. Each component has a specific role that contributes to the overall performance, and recognizing them can significantly enhance efficiency and safety. Knowing how to identify and manage these parts allows users to maintain their equipment effectively and make informed decisions during repairs or upgrades.

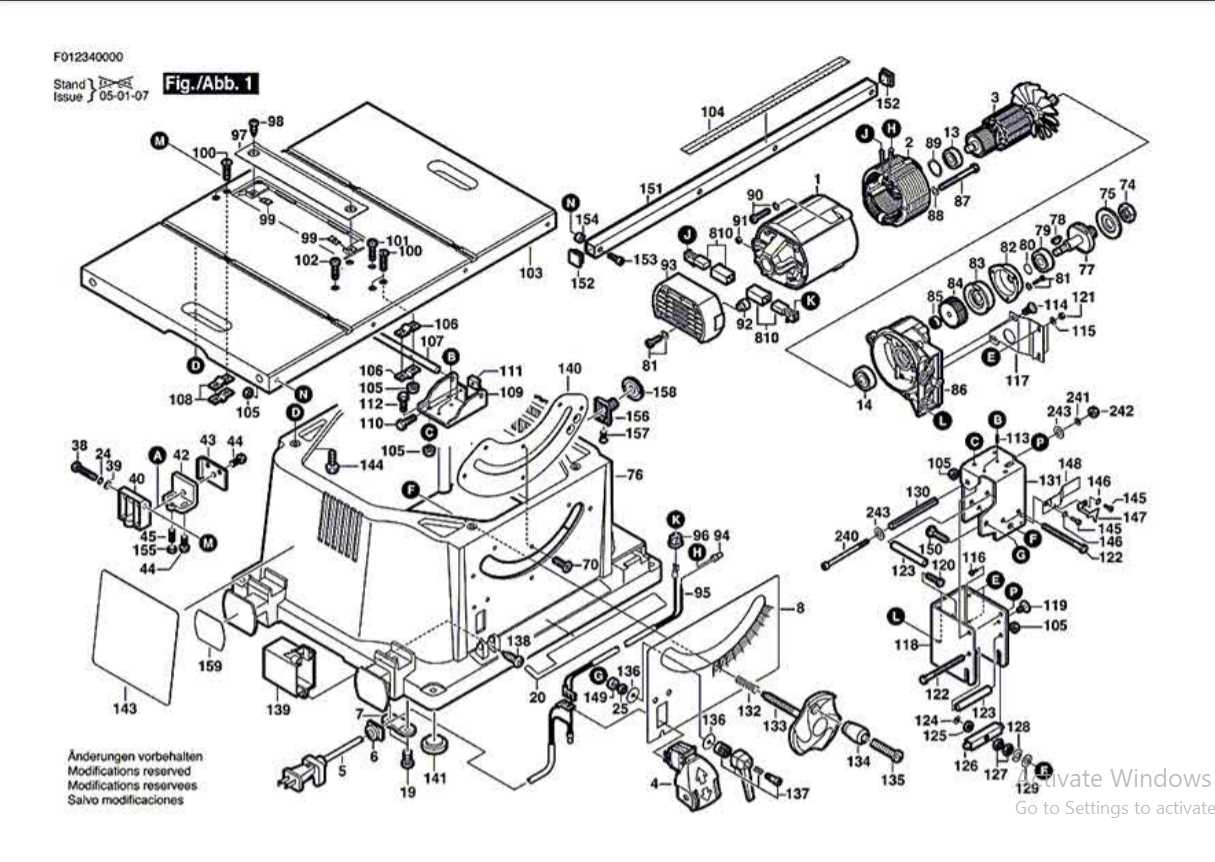

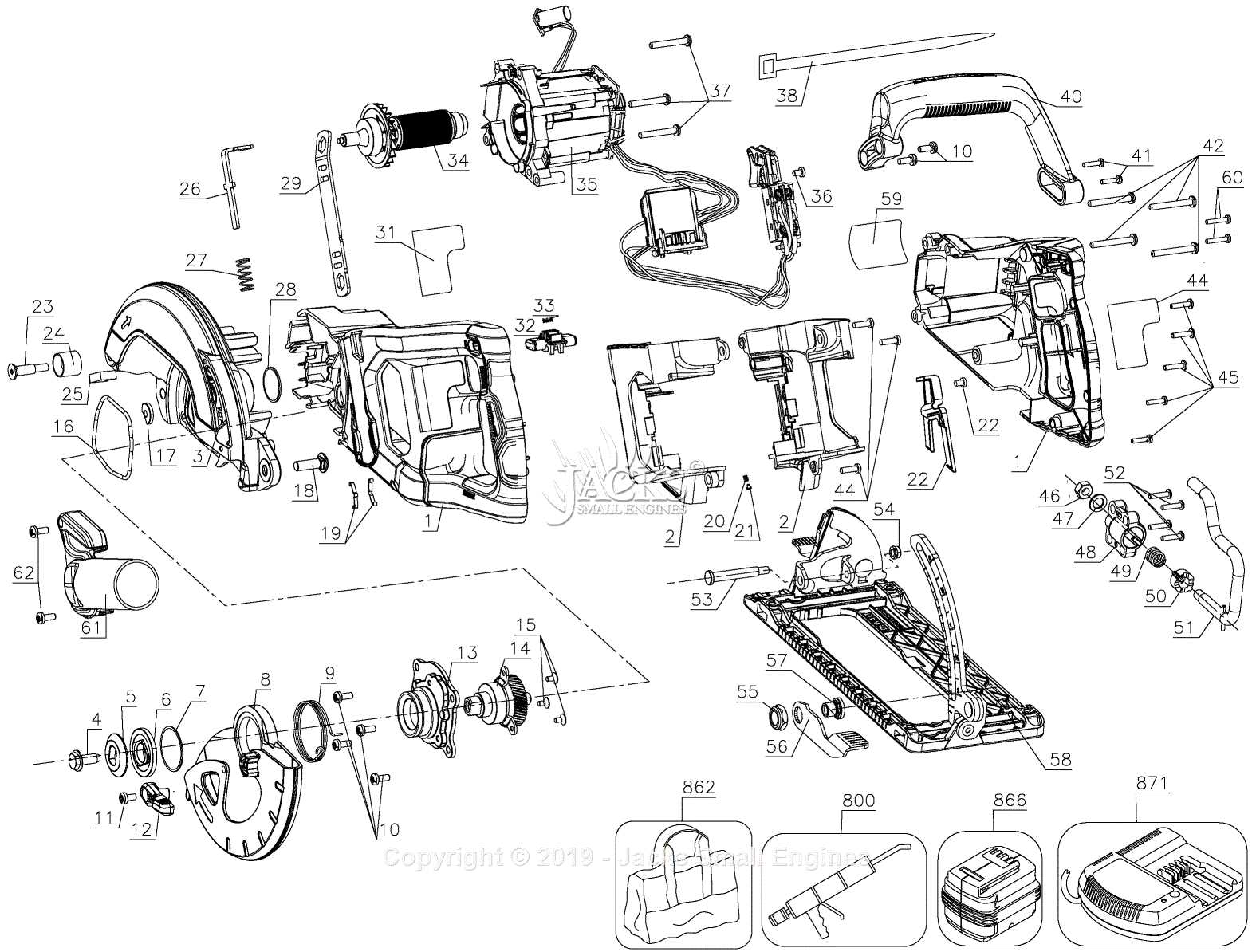

Many tools come with detailed visuals or breakdowns that provide a clear view of how these elements fit and work together. By interpreting these guides, users can better understand their devices, troubleshoot issues, and replace worn-out pieces with precision. Mastering this knowledge not only improves tool longevity but also ensures consistent results during usage.

Whether you’re a seasoned professional or a DIY enthusiast, familiarizing yourself with the internal workings of your equipment is a critical skill. With the right approach and a little guidance, handling maintenance tasks and repairs becomes much simpler. Knowing each component’s function ultimately leads to smoother, safer operations in your projects.

Understanding Tool Components and Their Functions

Each tool is made up of various individual elements that come together to perform specific tasks. Recognizing the function of each component helps users ensure smooth operation and identify any areas that may need attention. A clear understanding of these components allows for easier troubleshooting, repairs, and proper maintenance, contributing to the overall efficiency and durability of the equipment.

Identifying Key Elements

The primary elements of any mechanical device are often the most crucial for its performance. These may include the motor, drive mechanism, housing, and cutting mechanisms. Each of these pieces plays an integral role in how the tool operates and how effectively it performs its intended function. Knowing how these components work together enables users to diagnose issues quickly and prevent further damage.

Importance of Regular Maintenance

Proper care and routine checks of your tool’s individual components can significantly extend its lifespan. Regularly cleaning and inspecting these elements ensures they are functioning as intended, reducing the risk of breakdowns. By staying proactive with maintenance, users can avoid costly repairs and enjoy better performance from their equipment over time. Familiarity with each part’s role also provides more confidence in making necessary adjustments or replacements when needed.

How to Read Tool Component Breakdown

When dealing with a mechanical tool, it’s important to understand how to interpret visual guides that showcase its internal elements. These guides are essential for identifying and understanding the relationship between the different components. Learning how to read these detailed visuals helps users accurately recognize the parts that require attention or replacement, ensuring efficient repairs and proper maintenance.

Interpreting Visual Representations

These visual aids typically display each component in a clear and organized manner, often using numbers or labels to indicate the specific piece. It’s crucial to follow the flow of the diagram and pay close attention to the annotations that explain each element’s function and location. By doing so, users can pinpoint which pieces need to be removed or replaced without confusion.

Understanding Component Relationships

While interpreting these breakdowns, understanding how the elements fit together is key. Each part works in conjunction with the others to create the tool’s functionality, so recognizing these connections ensures that everything is reassembled correctly. Whether for troubleshooting or upgrading, a clear understanding of how components interact will make the process more efficient and effective.

Common Tool Components and Their Functions

Every tool consists of several core components that play specific roles in ensuring proper operation. Understanding the function of these essential elements is crucial for maintaining the tool’s effectiveness and longevity. Each piece contributes to the overall performance, and knowing their purpose helps users troubleshoot, repair, or replace them as needed.

Essential Components for Functionality

The motor is the heart of any tool, powering the entire system. Alongside the motor, the housing protects the internal mechanisms and provides stability during operation. Other key elements include the drive mechanism, which transfers energy, and the cutting mechanism, which performs the tool’s primary task. Each of these components works in harmony to ensure smooth and effective usage.

Commonly Replaced Elements

Over time, certain components tend to wear out or get damaged. These may include brushes, switches, and bearings. Routine checks of these elements help prevent malfunctions and ensure continuous performance. By recognizing when these parts need replacement, users can keep their equipment running smoothly and avoid costly repairs.