Understanding the structure and function of key elements in your outdoor equipment is crucial for efficient use and long-lasting performance. Whether you’re handling repairs, replacements, or simple maintenance, familiarizing yourself with the various components can save time and reduce frustration.

In this guide, we will explore how to identify and manage the essential parts of your tool, offering clear insights into the most common issues that may arise. With an emphasis on practical repair advice, this article will help you maintain optimal functionality and avoid costly errors.

By following this straightforward breakdown, you will be equipped to address minor and major malfunctions with confidence. Ensure smooth operation by mastering the maintenance of your device’s critical pieces and learning when and how to make replacements or repairs.

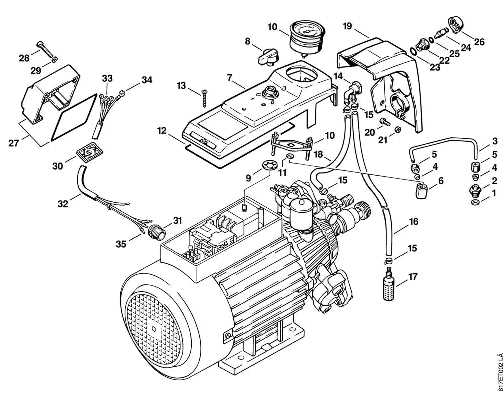

Understanding Stihl BR400 Parts Layout

When it comes to maintaining and repairing outdoor equipment, having a clear understanding of how the internal components are arranged is essential. Knowing the layout allows for easier troubleshooting, better management of repairs, and ensures that each part is functioning as intended for smooth operation.

Identifying Key Components

The first step in understanding the layout of your tool is recognizing its key elements. From the engine to the various attachments, each part plays a vital role in the overall performance. By becoming familiar with these elements, you can identify potential issues faster and address them with the right solutions.

Maintenance and Repair Insights

Properly maintaining each component ensures the tool operates efficiently for longer periods. Regular checks on the arrangement of internal pieces help detect wear and tear early, making repairs much simpler and preventing more serious damage in the future. Understanding the layout not only saves time but also helps avoid unnecessary replacement costs.

Common Issues and Repair Tips for BR400

Outdoor equipment, like all machines, is prone to certain issues over time. Understanding these common problems and how to address them is key to maintaining reliable performance and avoiding downtime. Recognizing symptoms early can help in diagnosing the root causes and implementing effective solutions.

Frequent Malfunctions

Here are some common malfunctions that can occur during regular use:

- Starting Issues: Difficulty starting the equipment could be caused by clogged fuel filters, spark plug wear, or issues with the ignition system.

- Overheating: Lack of proper ventilation or a damaged cooling system can lead to overheating, potentially damaging internal components.

- Loss of Power: Reduced engine power may result from air filter blockage, fuel mixture problems, or worn-out engine parts.

- Unusual Noises: Grinding or squealing sounds often indicate mechanical issues like misaligned parts or low lubricant levels.

Repair Recommendations

To address these issues effectively, consider the following repair tips:

- Inspect and clean the fuel and air filters regularly to avoid clogging, ensuring proper airflow and fuel delivery.

- Replace spark plugs as necessary and check the ignition system to ensure optimal start-up performance.

- Ensure cooling fins are free of debris and verify that cooling components are working efficiently to prevent overheating.

- Check and lubricate moving parts regularly to reduce friction and prevent damaging noises.

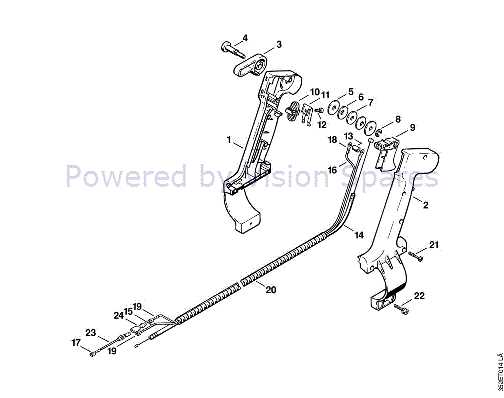

How to Replace Stihl BR400 Components

Replacing worn or damaged components in your outdoor tool is essential for maintaining its performance and extending its lifespan. Knowing the proper steps to take ensures that the replacement process goes smoothly and that your equipment continues to operate as efficiently as possible.

Preparation and Safety

Before starting the replacement process, make sure you have the necessary tools and replacement parts on hand. Always disconnect the power source, whether it’s the battery or fuel supply, to prevent accidents during the repair. Wearing protective gloves and eyewear is also recommended to safeguard against any debris or sharp edges.

Step-by-Step Replacement

Follow these basic steps to replace the damaged components:

- Step 1: Identify the part that needs replacing, using the equipment’s manual or an online guide for assistance.

- Step 2: Remove any surrounding components or covers to access the faulty part. Keep track of screws or bolts that are removed during this process.

- Step 3: Carefully detach the damaged component, taking note of how it is connected. This will help you during the installation of the new part.

- Step 4: Install the new part by aligning it properly with the other components. Secure it in place using the appropriate screws or bolts.

- Step 5: Reassemble any covers or parts you removed earlier. Ensure everything is tightened and properly secured before testing the tool.

After completing the replacement, it’s important to test the equipment to ensure the new part is functioning correctly. If any issues persist, double-check the installation or consult a professional technician for assistance.