Understanding the intricate details of a power tool’s assembly is crucial for effective maintenance and repair. Whether you are a seasoned professional or a hobbyist, knowing how each component fits together ensures smooth operation and longevity of your equipment. This guide provides an overview of the essential elements that make up the system, giving you a clear view of the mechanical structure.

By familiarizing yourself with the internal and external components, you gain the ability to identify potential issues before they escalate. Regular checks and proper part replacements are key to maintaining peak performance. This guide will break down the various components, illustrating their roles and helping you recognize which pieces may need attention or replacement.

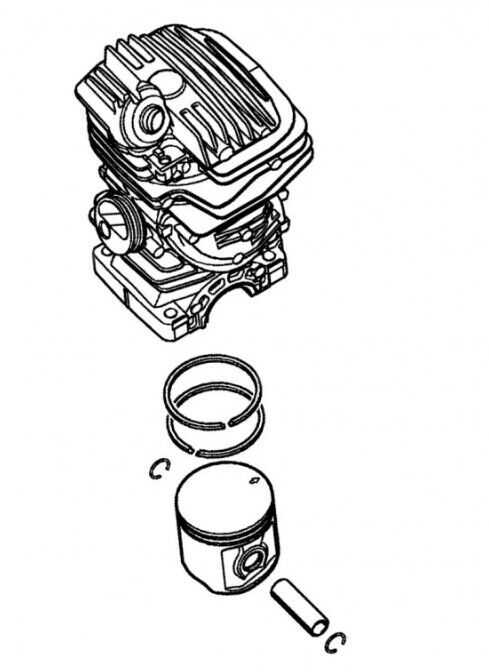

Understanding the Engine Components

In any mechanical system, each individual piece plays a crucial role in ensuring smooth and efficient operation. A clear understanding of how these parts interact allows for better maintenance and troubleshooting. By recognizing the function of each component, users can avoid unnecessary repairs and ensure optimal performance over time.

The main components of this type of tool include the power unit, fuel system, and chain mechanism, each contributing to the overall efficiency. Familiarizing yourself with their structure and placement helps in both recognizing wear and tear and performing necessary fixes. This understanding also supports efficient disassembly, making repairs quicker and less complex.

Regular inspection of these components is vital, as it allows you to catch potential issues early on. Whether dealing with the engine block, exhaust, or the cutting mechanism, knowing the role of each part empowers you to identify problems and take the necessary steps before they affect the tool’s functionality.

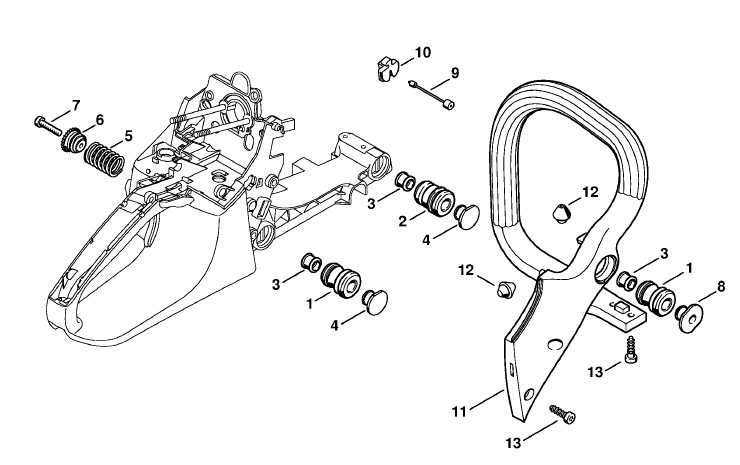

How to Identify Spare Components

Proper identification of the components within your equipment is essential for effective repairs and maintenance. Recognizing which part needs replacement can save both time and effort, ensuring the machine remains in peak working condition. This section will guide you through the process of identifying individual pieces based on their function, appearance, and compatibility.

Recognizing Key Elements

Start by understanding the basic structure of the tool and its main systems. Key components such as the engine block, fuel system, and cutting mechanism are essential for the tool’s operation. Each part has a specific role, and knowing where these elements are located will help you pinpoint replacements more easily. For instance, if the cutting performance is reduced, the issue may lie in the chain or sprocket assembly.

Using Manufacturer Documentation

For precise identification, always refer to the manufacturer’s official guides and documentation. These resources provide detailed illustrations of each component and offer valuable information on compatibility and installation. You can cross-check part numbers and shapes to ensure the correct replacement part is selected, minimizing the risk of purchasing an incorrect item.

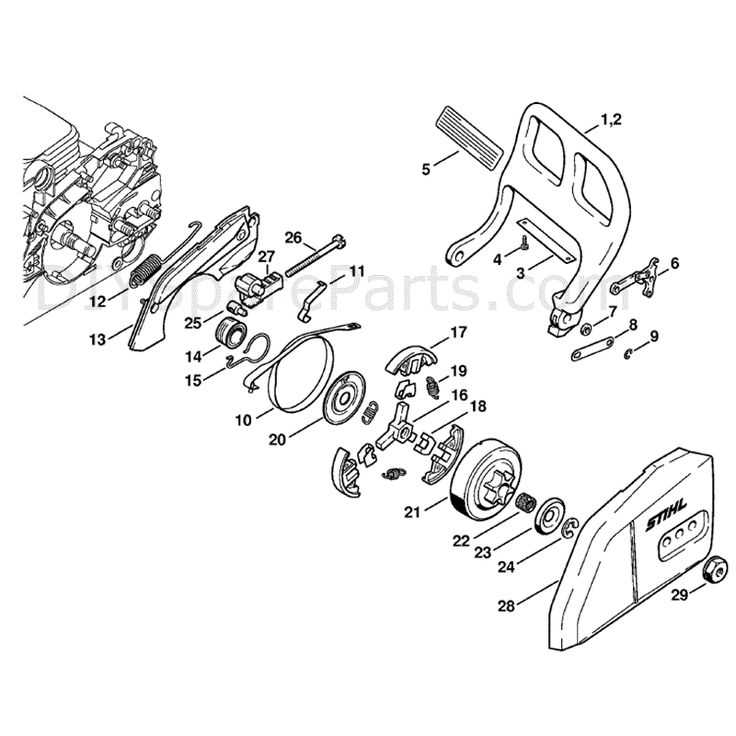

Step-by-Step Guide for Assembly

Assembling a mechanical tool requires attention to detail and methodical steps to ensure everything is properly aligned and functional. Each phase of the assembly process should be approached carefully, ensuring that all components are securely fitted and properly positioned. This guide will walk you through the entire assembly process, step by step, to help you complete it efficiently and accurately.

The first step is to start by gathering all necessary components and tools before beginning the assembly. This ensures that everything is within reach and ready for installation. Begin with the engine unit, making sure that it is placed in a stable position to prevent any movement during assembly. Attach the primary components, such as the fuel system, ensuring that each connection is tight and free from leaks.

Next, move on to the cutting mechanism and related parts. Carefully install the chain or blade assembly, checking that it is aligned correctly and securely fastened. Be sure to adjust tension as needed to avoid any operational issues. Finally, conduct a full inspection to confirm that each part is in place and that the tool is ready for use.