When it comes to maintaining your snow clearing equipment, having a clear view of the essential components is crucial. Knowing how each part functions and where it fits helps ensure smooth operation throughout the winter season. With the right tools and knowledge, repairs and upkeep become simpler tasks.

Exploring the individual elements of your machine can guide you in diagnosing issues quickly. Familiarizing yourself with the key mechanisms allows you to address problems effectively, whether it’s a broken drive system or a malfunctioning chute. A proper understanding of the machine’s layout saves time and minimizes repair costs.

By carefully studying the various components, you can easily pinpoint the cause of any malfunction. Whether it’s replacing a worn-out gear or fixing a misaligned motor, a clear understanding of how each part interacts will simplify your maintenance process, ensuring your equipment lasts longer and performs better.

Understanding the Snow Blower Components

For optimal performance and smooth operation, it’s essential to have a clear understanding of the main components within your snow clearing equipment. Each part plays a specific role in the overall functionality, from the engine to the chute. Familiarity with how these pieces work together helps in performing accurate diagnostics and repairs.

The core elements of the machine include the motor, auger, impeller, and drive system. Each of these components contributes to the efficiency and power of the snow blower. By learning about their functions and positions, users can quickly spot any areas that may need attention.

In addition to mechanical parts, electrical components are also vital to the system’s operation. The ignition system, wiring, and safety mechanisms ensure that the equipment starts and functions correctly. Understanding the integration of both mechanical and electrical systems can aid in troubleshooting and maintenance tasks.

How to Identify Components in the Blueprint

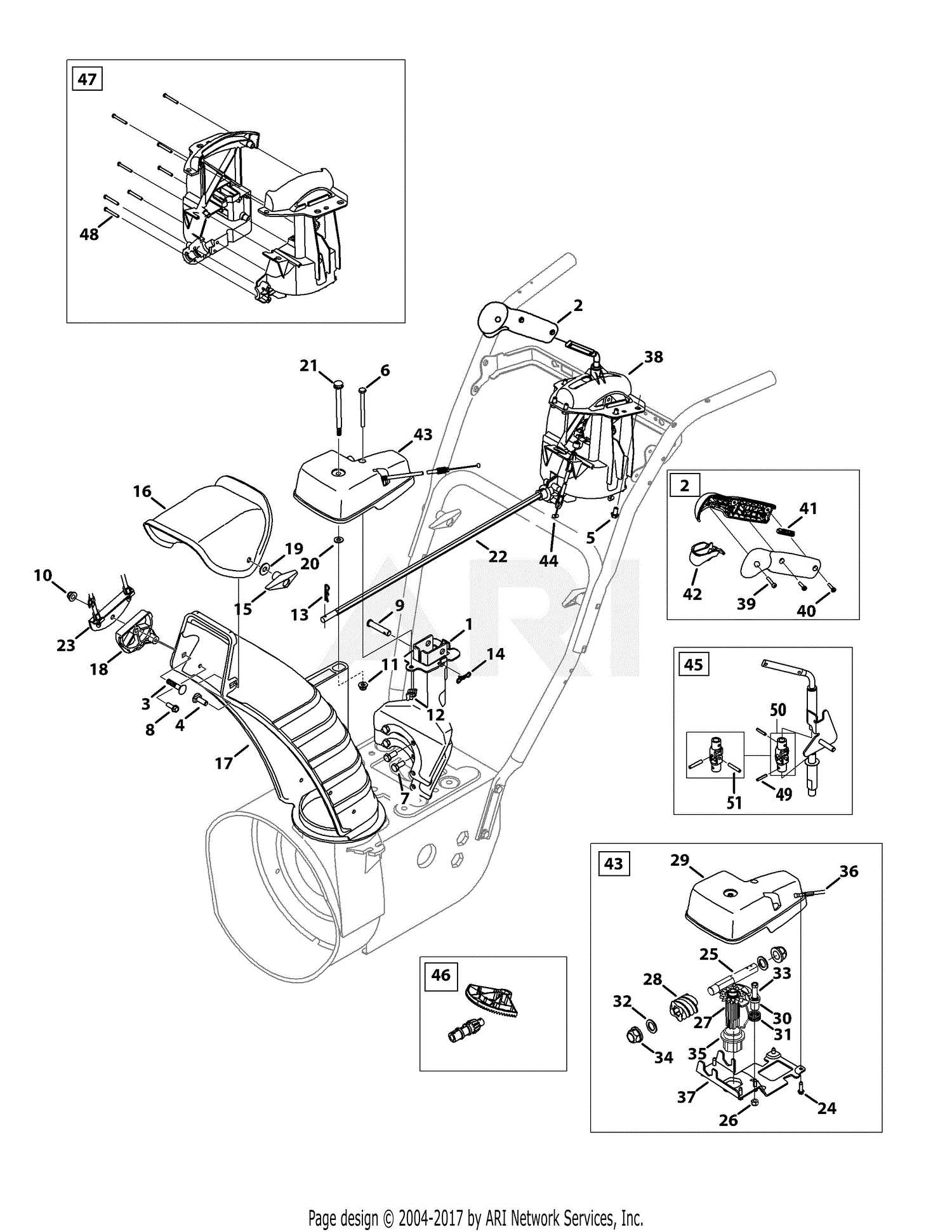

Identifying individual elements in your snow clearing equipment’s blueprint is a crucial step in understanding how everything fits together. Each part is represented with specific labels and numbers, allowing you to easily locate, compare, and replace components as needed. Familiarity with these symbols and identifiers makes the repair process more straightforward and efficient.

Recognizing Key Symbols and Labels

Every machine blueprint includes a set of standardized symbols and labels that correspond to different components. These symbols are designed to help users quickly identify each part. Pay close attention to these labels, as they typically include reference numbers that can be matched to a parts list, simplifying the search for the exact component you need.

Cross-Referencing with Manuals

Once you’ve identified the key components, cross-referencing the blueprint with the manufacturer’s manual is essential. The manual often provides additional details, including part numbers, sizes, and installation instructions. This reference ensures you select the correct replacement parts and helps avoid common errors during repairs.

Common Repairs with Snow Clearing Equipment

Regular maintenance is essential for ensuring the longevity and performance of your snow blower. Some common repairs can be easily handled by understanding the machine’s structure and knowing where issues typically arise. Familiarity with frequent problems allows users to take proactive steps in maintaining their equipment, avoiding costly repairs and downtime.

Fixing a Jammed Auger

A jammed auger is one of the most frequent issues encountered with snow blowers. It usually happens when debris such as ice, twigs, or rocks gets caught in the auger blades. Clearing the blockage often involves removing the debris and inspecting the auger’s blades for any signs of damage. Regularly checking this component and ensuring it’s free from obstructions will reduce the risk of jams.

Repairing the Drive System

If the drive system stops working, it can prevent the machine from moving forward or backward. This issue is often caused by worn-out belts, loose connections, or malfunctioning motors. Diagnosing the problem requires inspecting the belts for wear and tear and checking the motor and drive gears for proper function. Replacing a worn-out belt or tightening loose connections usually solves the issue.