Maintaining and repairing machinery can often be a challenging task, but having a clear understanding of its internal components simplifies the process. Proper knowledge of how different elements work together is essential for effective repairs and replacements. Whether you are a professional or an enthusiast, it’s crucial to have the right resources at your disposal.

Accurate identification of each machine component is vital for determining the necessary steps to restore functionality. Accessing comprehensive guides and resources ensures that you can pinpoint potential issues with precision and avoid unnecessary confusion. The right approach can save both time and money.

By learning more about the mechanical structure and key features of any machine, you can confidently address any issues that arise. This foundational knowledge helps you make informed decisions, enhancing the reliability and longevity of your equipment.

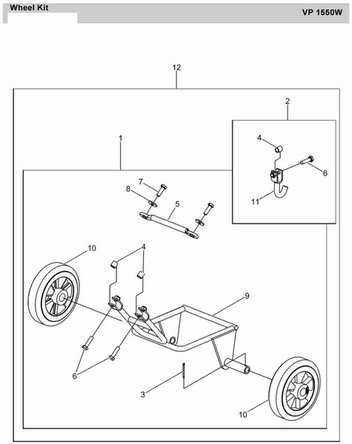

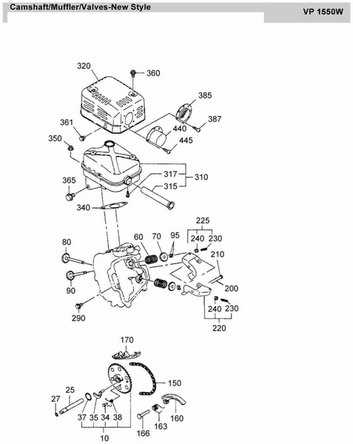

Wacker WP1550 Parts Breakdown

Understanding the internal structure of any mechanical system is essential for efficient repair and maintenance. Each machine contains several interconnected components that contribute to its overall functionality. Recognizing the key elements helps in diagnosing issues, sourcing the right replacements, and ensuring long-term performance.

By breaking down the system, it’s easier to pinpoint specific sections, such as the engine, transmission, and auxiliary components, which play critical roles in the machine’s operation. Each part serves a unique function, and when one fails, it can impact the entire system. Therefore, a clear understanding of each part’s role is vital.

Having a detailed breakdown not only assists in repairs but also helps in routine maintenance. Regular inspection of these components can prevent unexpected failures and extend the lifespan of the equipment. Knowing where each part is located and how it interacts with others makes any task more straightforward, reducing downtime and costs.

Identifying Key Components in WP1550

To ensure smooth operation, it’s crucial to understand the primary elements of any mechanical system. By identifying the core components, one can easily assess their condition and make informed decisions about repairs or replacements. These essential parts work in harmony to maintain efficiency, so recognizing each one’s purpose is key to successful maintenance.

Engine and power systems are often the heart of any equipment, providing the necessary force to perform tasks. Alongside the power source, control mechanisms and transmission components play an equally important role in directing and regulating that power. A proper understanding of these systems helps identify potential areas for failure.

The auxiliary parts and support systems also deserve attention. These parts often include vital accessories that contribute to the overall functioning of the machine, from cooling mechanisms to safety features. Regular checks on these elements help to keep operations running smoothly and prevent more serious malfunctions.

Understanding Wacker WP1550 Repair Parts

Knowing the available repair components for any machine is essential for ensuring it continues to function properly after a failure. Each component serves a unique purpose, and understanding these roles can significantly impact the ease and success of the repair process. Whether it’s for a minor fix or a major overhaul, having the right parts is key to restoring the equipment to optimal performance.

Replacement elements range from small connectors and seals to larger, more complex mechanical systems. These components are designed to fit seamlessly into the machine, allowing for smooth operation once replaced. In many cases, the quality of the replacement directly impacts the longevity of the machine.

Access to genuine or compatible replacements ensures that the equipment performs at its best, maintaining its efficiency and preventing further breakdowns. Having a clear understanding of the necessary repair elements not only speeds up the repair process but also prevents errors in selecting inappropriate components for the job.