In construction and heavy machinery, knowing the essential components that make up the equipment is crucial for ensuring efficiency and longevity. A clear understanding of how each element works together helps operators perform tasks with precision and care. These machines are designed to handle tough jobs, but their intricate systems require proper knowledge for effective usage and maintenance.

Every machine consists of several key units, each with a specific role in its operation. Identifying these units and recognizing their functions allows operators to troubleshoot problems, conduct repairs, and perform regular maintenance. From the lifting mechanism to the control systems, each part plays a critical role in the overall performance of the equipment.

By familiarizing yourself with the structure and functionality of these machines, you can gain valuable insights into improving their performance and extending their lifespan. Proper maintenance and timely repairs prevent costly breakdowns and ensure that machinery continues to run smoothly on demanding work sites.

Understanding the Components of a Heavy Machinery Machine

To effectively operate any heavy equipment, it’s essential to understand the core elements that contribute to its functionality. These machines rely on multiple interconnected systems, each responsible for specific tasks that enhance performance. Recognizing how these components interact can lead to more efficient operation and easier troubleshooting when issues arise.

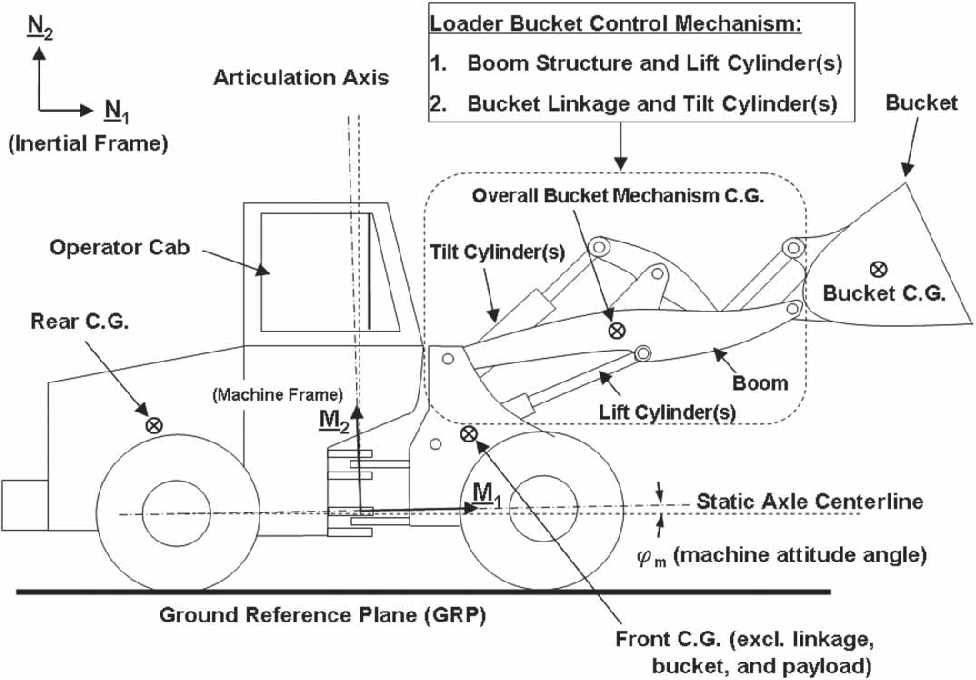

The Hydraulic System

One of the most vital components is the hydraulic system. It allows for the movement of large elements such as the lifting arm and the bucket. By using pressurized fluid, the system converts energy into force, enabling the machine to perform heavy-duty lifting and shifting operations. Proper maintenance of this system is essential to prevent leaks and ensure smooth performance during tasks.

The Steering and Control Mechanisms

The steering and control systems are responsible for maneuvering the equipment with precision. These systems are designed to provide responsive handling, even in tight spaces. A well-functioning control system ensures the operator can adjust movements with ease, making it essential for safety and operational efficiency.

Understanding these core components ensures better handling and maintenance of heavy machinery, prolonging its operational life and preventing costly breakdowns.

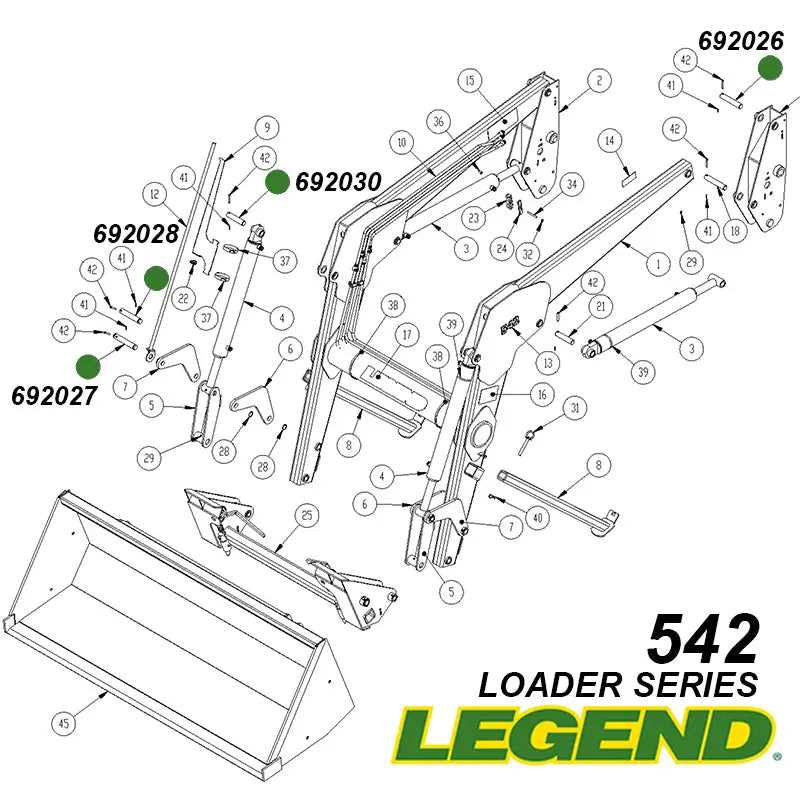

How to Identify Key Loader Components

Recognizing the essential elements of a heavy machine is crucial for ensuring proper operation and effective maintenance. By identifying key components, operators can better understand how each part contributes to overall performance and troubleshoot potential issues more efficiently. A comprehensive knowledge of these critical units can prevent costly repairs and improve machine longevity.

Visual Inspection of the Hydraulic Arm

The hydraulic arm is a primary element that facilitates lifting and lowering of materials. Inspecting this unit involves checking the hydraulic cylinders, hoses, and joints for any signs of wear, leaks, or damage. Ensuring these components are intact helps avoid malfunctions during operation and ensures the machine performs optimally under heavy loads.

Examining the Wheel and Steering Assembly

The wheel and steering system plays a crucial role in the machine’s maneuverability. Identifying key components within this system includes checking the tires, axles, and steering mechanisms for any unusual wear or misalignment. Regular inspection of these parts ensures smooth navigation on job sites, especially in tight spaces or rough terrain.

By familiarizing yourself with these components, you can identify issues early on, reducing downtime and improving the overall efficiency of the machine.

Importance of Proper Maintenance for Heavy Machinery Components

Regular upkeep of a machine’s vital components is essential for ensuring reliable performance and preventing unexpected failures. Consistent maintenance not only extends the lifespan of the equipment but also helps maintain its efficiency and safety. Neglecting essential servicing can lead to costly repairs and downtime, which could impact overall productivity.

Preventing Wear and Tear

Routine checks and maintenance of high-stress components, such as the hydraulic system and mechanical joints, are critical in preventing excessive wear and tear. By replacing worn parts and addressing minor issues early, operators can avoid major breakdowns and reduce the likelihood of machine failure during critical tasks.

Ensuring Operational Efficiency

Maintaining key units like the engine, steering mechanism, and lifting system ensures that the machine operates smoothly and efficiently. Proper lubrication, timely fluid changes, and routine inspections keep these systems functioning at peak performance. Well-maintained machinery uses less fuel and minimizes the chances of unexpected interruptions during operations.

Incorporating regular maintenance schedules into the operation of heavy machinery leads to significant cost savings and more productive work environments.