Maintaining and repairing any equipment requires a clear understanding of its internal structure. Knowing how the various elements of a machine are interconnected can make troubleshooting and upkeep much easier. Properly identifying each part is crucial to ensure the device functions optimally over time.

In this section, we will explore the layout of the essential components within a high-performance cleaning device. By referencing a well-organized schematic, users can familiarize themselves with the core sections of the machine. This understanding provides both the confidence and knowledge needed for effective maintenance or repairs.

Knowing the functions of each individual component and how they work together will enhance the user’s ability to spot issues before they become serious. Furthermore, such diagrams serve as an invaluable tool for efficient troubleshooting, enabling swift identification and resolution of problems.

Understanding Ex-cell 2500 Parts Layout

To maintain and repair a high-performance cleaning unit, it’s essential to have a clear view of its internal structure. A well-constructed schematic allows users to identify each component, making it easier to locate issues and ensure proper functionality. Understanding how these elements are arranged and connected is vital for anyone involved in upkeep or troubleshooting.

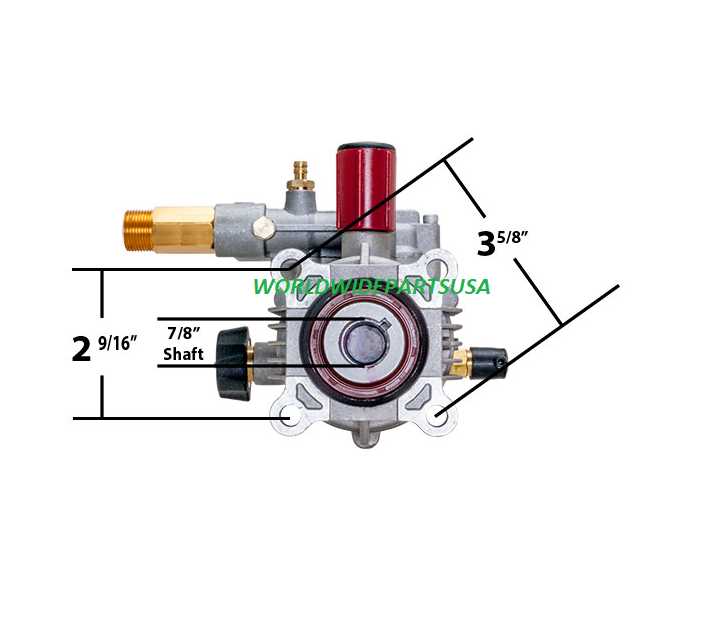

The layout of the machine includes several key sections, each responsible for specific tasks. From the motor assembly to the nozzle configurations, each part plays an important role in the unit’s overall operation. By familiarizing oneself with this organization, users can more effectively navigate the machine’s internal workings.

Knowing the precise location of each component ensures that repairs can be made efficiently, reducing downtime. Whether performing routine maintenance or resolving specific issues, a solid grasp of the machine’s structure supports quick and accurate actions, leading to optimal performance and longevity.

Key Components of Ex-cell 2500 Washer

The functionality of any cleaning unit depends on its various integral components, each designed to serve a specific role. Understanding these parts is crucial for effective maintenance and troubleshooting. By identifying the core elements that drive the machine’s performance, users can better manage its upkeep and ensure long-lasting reliability.

The motor is the heart of the system, providing the necessary power for operation. The pump works in conjunction with the motor to move water efficiently, while the spray gun and nozzle configurations control the direction and intensity of the flow. Additionally, hoses, filters, and pressure regulators are vital in ensuring consistent and safe operation.

Each component plays a significant role in the overall functionality of the unit. Regular inspection and understanding of how these parts interact can help identify potential issues early and allow for prompt resolution, maintaining the equipment’s optimal performance over time.

How to Use the Parts Diagram Effectively

Utilizing a visual guide of the internal components of a device is an essential step in performing maintenance and repairs. These schematics offer a clear view of the machine’s structure, allowing users to quickly identify specific areas that require attention. Understanding how to read and interpret these guides can greatly enhance troubleshooting efficiency and accuracy.

Begin by familiarizing yourself with the layout and labeling conventions used in the guide. Pay close attention to the numbers and names of each part, as these will help in locating components during disassembly or reassembly. A thorough understanding of the diagram ensures you can pinpoint issues and verify the correct replacement or adjustment of specific parts.

Additionally, the schematic can assist in preventive maintenance by showing wear-prone areas or parts that require periodic checks. By referring to it regularly, users can stay ahead of potential problems, ensuring the longevity and smooth operation of the equipment.