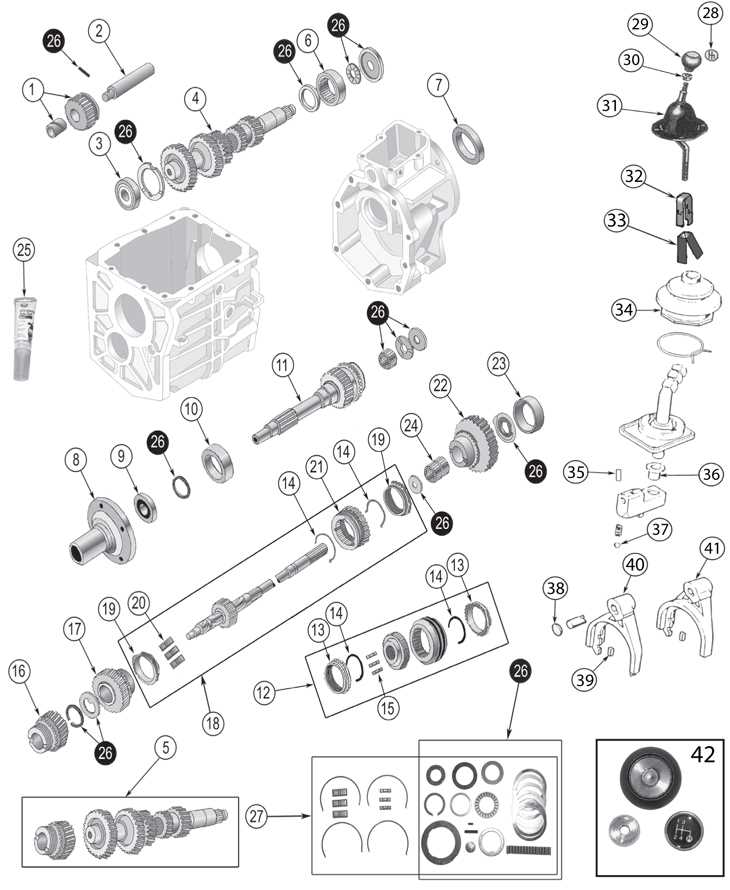

When working with vehicle transmissions, it’s essential to have a clear understanding of the individual components that make up the system. Each part plays a crucial role in the proper functioning of the mechanism, and knowing how they interact can significantly aid in maintenance and repairs.

The intricate layout of these components can sometimes be challenging to decipher, especially for those unfamiliar with mechanical systems. Having a detailed illustration or reference guide allows for a clearer perspective and helps prevent mistakes during disassembly or reassembly.

Maintaining a transmission requires careful attention to each element. From small gears to larger structural components, understanding their placement and function ensures that repairs are conducted correctly. This guide provides insights into the construction and typical issues, aiming to simplify the process for both novice and experienced technicians.

Understanding Transmission Components

In any manual transmission system, numerous components work together to ensure smooth shifting and overall functionality. These elements include everything from the gears and shafts to the synchronizers and bearings. Each piece has a specific role, and when maintained correctly, they ensure the transmission operates efficiently. Understanding how these parts interact with one another is vital for anyone working on or repairing transmissions.

Key Mechanical Elements

The primary components that contribute to the transmission’s effectiveness include the gear sets, input shafts, and output shafts. These pieces are responsible for transmitting the power from the engine to the wheels, allowing for proper acceleration and deceleration. Gears within the system are arranged in a manner that facilitates different speeds and torque distribution. Additionally, the use of synchronizers enables smooth gear shifts without grinding or jamming.

Challenges in System Assembly

When disassembling or reassembling the system, it is crucial to understand how each component fits together. Improper assembly can lead to a host of issues, including misalignment, excessive wear, or even complete failure. Attention to detail and a comprehensive understanding of each component’s role will prevent common mistakes and ensure longevity for the system.

How to Read the Transmission Assembly Breakdown

When working with a mechanical system, understanding its layout is essential for any repair or maintenance task. A clear illustration of the system’s components allows technicians to identify each part and its relationship with the others. Learning to read and interpret such diagrams is a key skill in ensuring accurate assembly and troubleshooting.

Identifying Components and Their Functions

Each symbol or label on an assembly guide corresponds to a specific component. It’s crucial to understand what each symbol represents, as well as how the parts fit together. The guide often includes detailed views of individual parts, showing their orientation and how they interact with the other elements within the system. Understanding these references will allow you to follow the system’s layout efficiently and avoid confusion during repairs.

Understanding Reference Numbers and Labels

Most diagrams include reference numbers or codes next to each component. These numbers link directly to parts lists or detailed descriptions, making it easier to source replacements or understand a part’s function. Attention to these details ensures that the assembly is carried out with precision, reducing the likelihood of errors during the reassembly process.

Common Issues with Transmission Components

Like any mechanical system, the components of a manual transmission can experience wear and tear over time. These issues can lead to performance problems and, in some cases, complete failure of the system. Identifying common faults early can prevent costly repairs and improve the lifespan of the transmission. Understanding the typical problems that occur with these elements is essential for effective maintenance.

Gear Wear and Misalignment

One of the most frequent issues is the wear of the gears due to prolonged use or improper lubrication. Over time, gears may become misaligned, leading to slipping or difficulty in shifting. Misalignment can cause grinding noises and even lead to complete transmission failure if left unaddressed. Regular inspections and proper maintenance can help prevent these issues from becoming severe.

Clutch and Synchronizer Problems

Another common issue is related to the clutch and synchronizer rings, which play a key role in smooth gear shifts. These parts can wear out or become damaged due to constant engagement and disengagement. Damaged synchronizers can cause hard shifting, while a faulty clutch may result in slipping or failure to engage certain gears. Timely replacement of these components is crucial to ensure smooth operation.