When maintaining a chainsaw, having a clear understanding of its internal and external components is essential for optimal performance. The proper functioning of each part plays a significant role in the overall efficiency of the machine. By familiarizing yourself with the key elements, you can ensure that the equipment runs smoothly and lasts longer.

Proper identification of each section allows users to perform routine checks, replace worn-out pieces, and make repairs as necessary. Whether you’re a professional or a hobbyist, knowing what makes up your tool is crucial for effective upkeep.

In this guide, we will break down the important elements of the device and how you can utilize available resources to identify, replace, or troubleshoot any issues. This knowledge empowers users to handle repairs with confidence and reduce downtime during use.

Understanding Chainsaw Components

Every chainsaw is made up of various critical elements, each serving a distinct function to ensure smooth operation. From the engine to the cutting system, understanding these components is essential for maintaining efficiency and preventing issues. Recognizing how each part interacts helps you to troubleshoot and perform necessary repairs with ease.

The engine assembly provides the power needed to drive the tool, while the fuel and ignition systems ensure proper combustion. The cutting mechanism, including the bar and chain, is responsible for the tool’s ability to slice through wood effectively. Additionally, the safety features integrated into the chainsaw help protect the user during operation.

To keep your chainsaw in optimal condition, it’s important to familiarize yourself with each part and its function. Regular inspection and maintenance of these components can prevent breakdowns and extend the life of your equipment.

How to Use the Chainsaw Blueprint

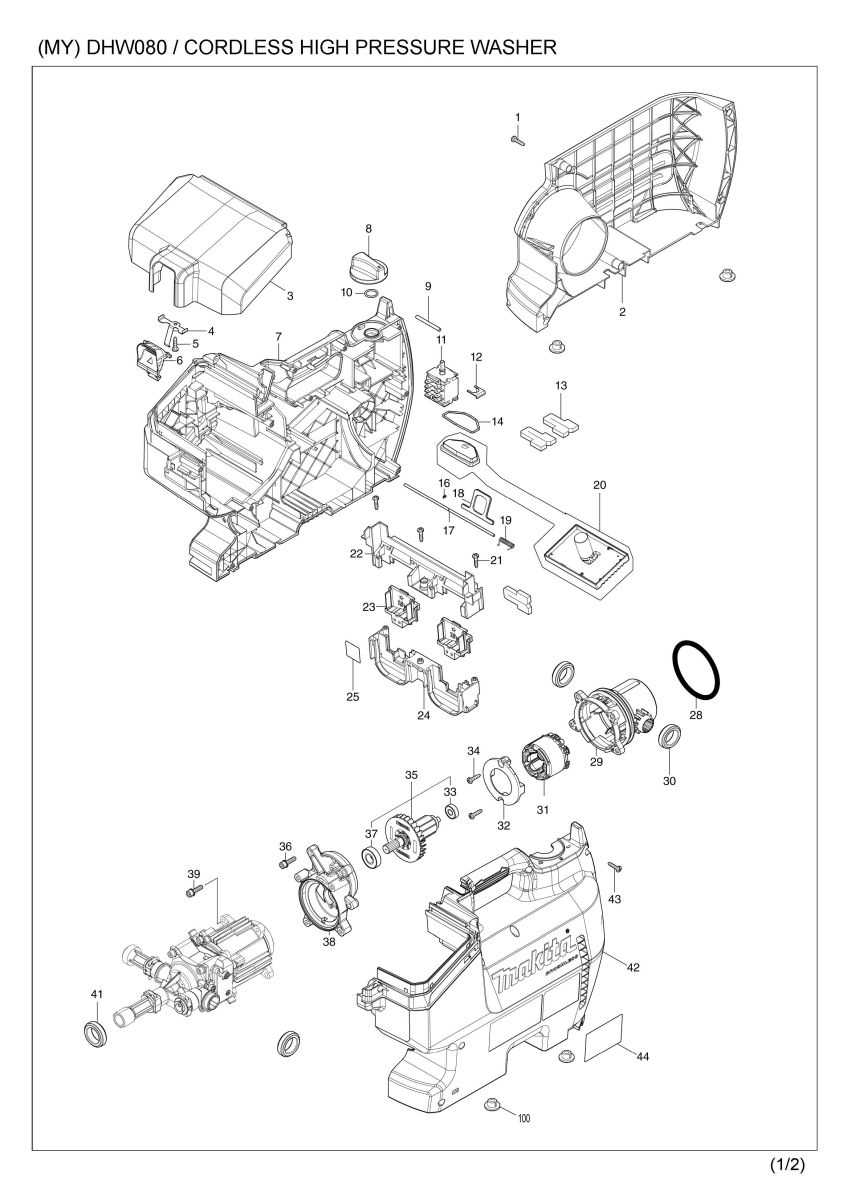

A blueprint or schematic of your chainsaw is an invaluable tool when it comes to maintenance and repairs. It allows you to clearly identify each element, understand its function, and determine where potential issues might arise. Using a detailed schematic helps you follow a structured approach when inspecting or replacing components.

Identifying Key Components

Start by reviewing the layout of major sections, such as the engine, fuel system, and cutting mechanism. The diagram typically labels each part, making it easier to find what you need. This will guide you in pinpointing worn-out or damaged components that need attention.

Following Maintenance Procedures

Once you’ve identified the necessary parts, refer to the schematic to understand how they fit together. This will help ensure that each component is reassembled correctly during repairs. A good understanding of the layout allows you to perform tasks like chain replacement or engine adjustments with greater accuracy and confidence.

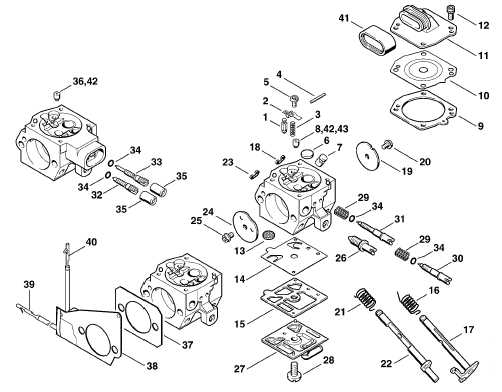

Common Components for Chainsaw Maintenance

Regular upkeep of a chainsaw involves several key elements that require attention to ensure optimal performance. These critical components must be checked periodically to prevent issues during operation and extend the lifespan of the tool. Familiarity with these parts will allow you to perform necessary replacements and adjustments when needed.

Fuel system components, including filters and fuel lines, should be inspected regularly for blockages or wear. A clogged filter can reduce engine efficiency and lead to poor performance. Similarly, the cutting mechanism, including the bar and chain, should be checked for damage or excessive wear to maintain smooth operation.

Air filters are another essential part of maintenance. They keep debris from entering the engine, which can cause overheating and reduced functionality. In addition, examining the ignition system and spark plug helps ensure reliable starting and proper engine combustion.