Maintaining a lawn tractor requires a clear understanding of its internal structure. Whether you’re performing routine maintenance or dealing with a breakdown, knowing the specific elements and how they interact is essential for efficient repairs. A visual representation of the various components can help ensure you’re selecting the right parts for replacement or repair.

Proper knowledge of the layout aids in troubleshooting common issues, saving both time and money. By following the outlines provided, you can avoid confusion and make repairs that restore your equipment’s functionality with confidence. This approach will guide you through identifying the right components to focus on, enabling smoother repair processes.

Familiarity with the assembly and internal workings will also prevent errors in maintenance and ensure the longevity of your equipment. Understanding how each piece fits together and its role in the overall system is crucial for tackling any potential problems effectively.

Understanding Tractor Components

To properly maintain and repair a lawn tractor, it is important to have a thorough understanding of its key elements. These machines are built with various interconnected systems, each playing a critical role in the overall function. By familiarizing yourself with the structure and functions of these components, you can ensure that you are always prepared for maintenance tasks.

Each component serves a specific purpose, whether it’s related to power generation, movement, or control. Familiarizing yourself with the engine, transmission, and steering elements, for example, is essential for diagnosing issues and performing repairs. Additionally, understanding how the parts work together allows for more precise troubleshooting, reducing downtime.

Recognizing the functions of individual elements can help you detect wear or failure signs early, allowing for timely interventions. Knowing where each piece is located and how it contributes to the overall performance of the machine provides a clear path to resolving issues, from simple maintenance to complex repairs.

Identifying Key Parts in the Diagram

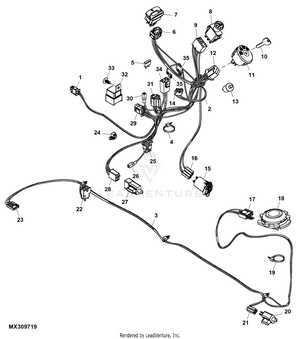

Recognizing the main components of a lawn tractor is a crucial step in ensuring proper maintenance and repair. Understanding which parts are responsible for essential functions helps to streamline the process of diagnosing issues and replacing damaged pieces. A detailed visual guide can provide clarity on how these elements fit into the overall system.

When identifying components, focus on the following categories:

- Engine components: These include the motor, carburetor, and spark plug, which are responsible for generating power.

- Transmission system: Key parts such as the gearbox and drive belts control the movement of the tractor.

- Steering mechanism: The steering column, rack, and pinion help guide the tractor’s direction.

- Electrical system: The battery, wiring, and alternator manage the power flow to various electrical components.

- Hydraulic parts: These include the lift arms, cylinders, and valves that enable the operation of attachments.

Each of these components plays a vital role, and understanding their function within the system can make troubleshooting much easier. By focusing on these key areas, you can identify issues quickly and confidently, ensuring your equipment remains in optimal working condition.

How to Use the Parts Diagram

Utilizing a visual guide for the internal structure of a lawn tractor can greatly simplify the process of finding and replacing faulty components. Understanding how to read and interpret these diagrams ensures that you focus on the correct parts, reducing errors and saving time during repairs.

Understanding the Layout

A well-structured illustration will categorize parts into sections based on their function. For example, engine components will be grouped together, while transmission and steering elements will be shown in different areas. This organization helps users quickly locate the component they need to inspect or replace.

Following the Legend and Symbols

Every diagram will include a legend or key that explains the symbols used for various components. Make sure to refer to this legend to correctly identify parts. Symbols may indicate the type of connection, whether it’s a screw, bolt, or clip, and highlight the orientation or arrangement of each element.

| Symbol | Meaning |

|---|---|

| Tool required for installation | |

| ⚙️ | Mechanical part (gear, bearing, etc.) |

| Electrical component (battery, wiring) |

By following these steps, you will be able to efficiently identify and understand the components within the visual guide, making the process of maintenance and repair straightforward and accurate.

Steps for Effective Maintenance and Repair

Proper upkeep and repair of machinery require a systematic approach to ensure longevity and optimal performance. By following a series of well-defined steps, you can prevent unexpected breakdowns and maintain the functionality of your equipment over time. Understanding the key components and their specific needs is essential to making the right decisions during maintenance and repair tasks.

The first step is to regularly inspect the equipment for any visible signs of wear or damage. This includes checking belts, filters, and fluid levels. It is important to clean and replace filters as needed to maintain air and fuel efficiency. In addition, tightening any loose bolts or fasteners ensures that the equipment remains in good working order.

The next step involves diagnosing potential issues based on the equipment’s behavior. If the machine is experiencing performance issues, refer to the specific components that might be affecting operation, such as the engine, transmission, or electrical systems. Referencing an illustration of the internal layout helps pinpoint the problem area more accurately.

Once the faulty component is identified, carefully disassemble the relevant parts, keeping track of screws, bolts, and other small elements to ensure proper reassembly. Always use appropriate tools and follow the correct procedures to avoid causing further damage. Replace the broken or worn parts with new ones that match the specifications of the original components.

Finally, after completing the repair, conduct a thorough test to ensure the machine is functioning as expected. Regularly servicing the equipment and addressing small issues promptly can prevent larger, more costly problems down the line.

Common Issues and Solutions

Machinery, like any complex system, is prone to wear and occasional malfunction. Identifying common issues early on and knowing how to address them can save both time and money. By focusing on the symptoms and understanding the underlying causes, many problems can be easily resolved through simple maintenance or part replacement.

Engine failure is a common issue that often arises from improper maintenance or fuel-related problems. If the engine is not starting, check the fuel lines for blockages, and ensure the battery is fully charged. If the engine sputters or runs unevenly, it may be due to a clogged air filter or spark plug. Replacing the filter and cleaning or replacing the spark plug should resolve the issue.

Transmission problems can lead to difficulty in moving the machine. This is often caused by worn-out belts or improper lubrication of moving parts. Regularly checking and replacing the drive belt, as well as ensuring proper lubrication of the gearbox, will prevent this issue. If the transmission is making unusual noises, it may indicate a more serious problem, such as a damaged gear, which will require professional attention.

Electrical issues are another common problem, particularly with wiring or battery connections. If the machine fails to start or lights flicker, inspect the battery for corrosion and ensure all wiring is properly connected. If the wiring is damaged or frayed, it should be replaced to prevent further electrical failures.

Regular inspections and proactive maintenance can help mitigate these issues, ensuring that the equipment continues to operate smoothly for years to come. Understanding these common problems and their solutions will make troubleshooting and repairs much more manageable, keeping your equipment in top shape.