Every mechanical system that involves a retractable feature relies on a specific set of components that work together to ensure smooth operation. These systems are commonly found in various industries, such as recreational vehicles, trailers, and other heavy-duty equipment. Understanding these components is essential for maintenance, troubleshooting, and repair. With the right knowledge, users can easily identify potential issues and handle them effectively.

Key Components of Retractable Mechanisms

Retractable mechanisms consist of multiple parts that must function in sync. These include motors, tracks, drive components, and linkages. Each of these elements plays a crucial role in ensuring the device moves smoothly and securely. Recognizing the purpose of each part helps in diagnosing malfunctions and selecting the correct replacement parts when necessary.

Motor and Drive Components

The motor is the heart of the mechanism, providing the necessary power to move the system. It works in conjunction with the drive components, such as gears or belts, to transmit movement efficiently. Over time, motors can wear out, leading to reduced performance. Regular inspection of these parts ensures that they are functioning correctly.

Tracks and Linkages

Tracks guide the movement of the mechanism, ensuring it operates in a straight line. Linkages connect different parts of the system and facilitate coordinated movement. If these parts become misaligned or damaged, it can cause the system to jam or malfunction. Proper lubrication and alignment are essential to keeping these parts in optimal condition.

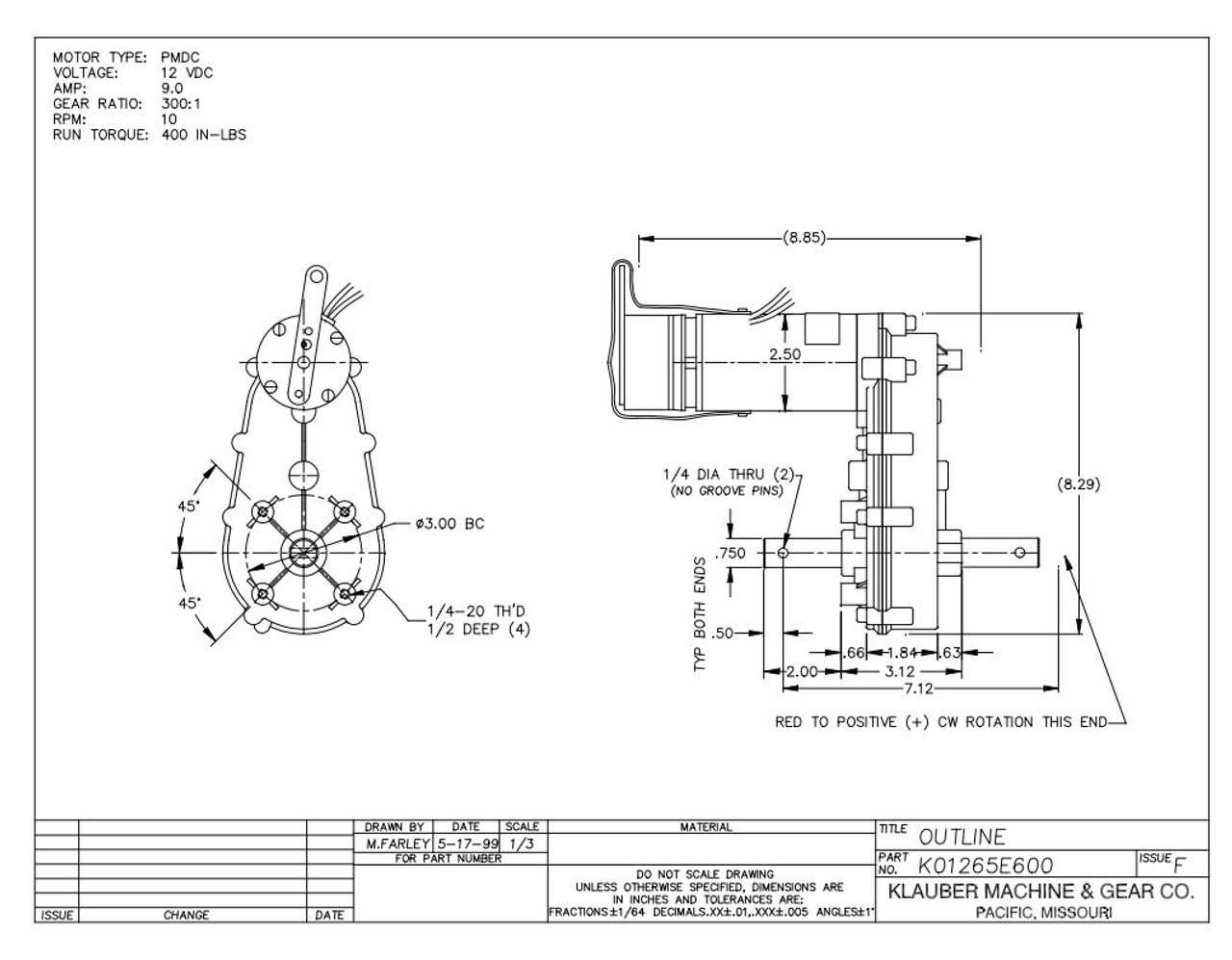

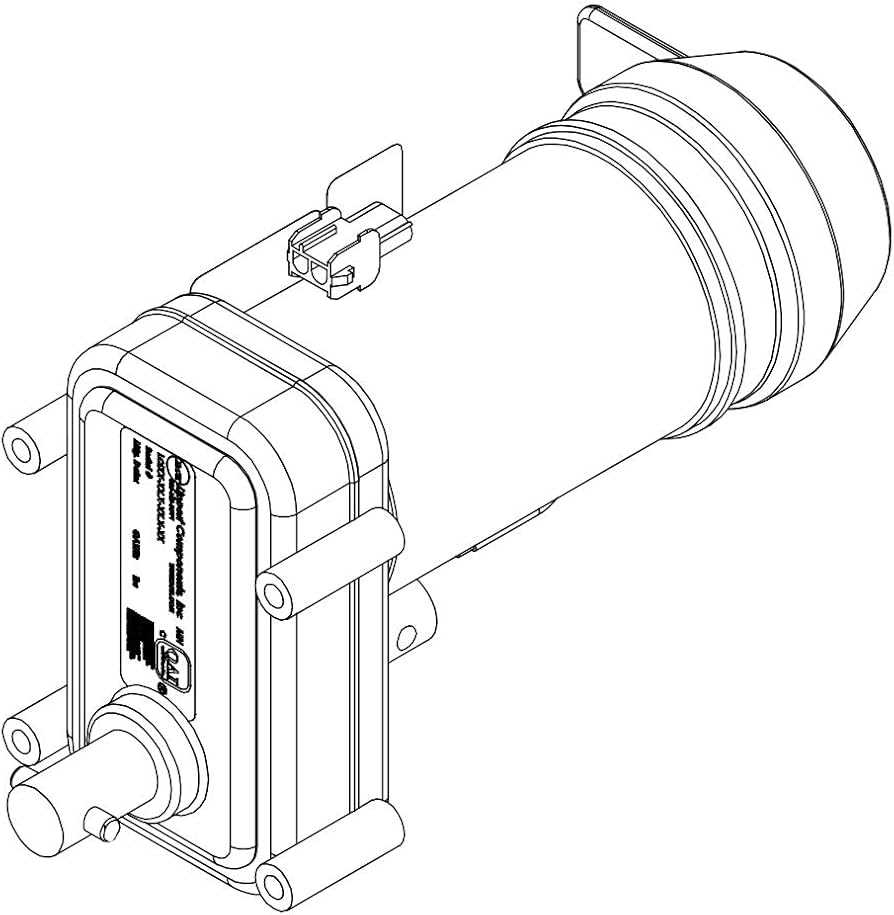

Using Diagrams for Easy Identification

Using detailed schematics or illustrations helps users quickly identify each component in a mechanical system. These visuals provide a clear representation of how parts are connected and function together. By referencing such resources, individuals can perform accurate assessments, replace defective components, and prevent further damage to the system.

Maintenance and Troubleshooting

Maintaining the system involves regular checks for wear and tear, ensuring that all parts are functioning as expected. Understanding how the individual components interact allows users to troubleshoot effectively. Whether it’s a minor adjustment or a significant repair, having a clear understanding of how everything fits together makes the process more straightforward and less intimidating.

Replacing Defective Parts

When parts need to be replaced, it’s important to use high-quality replacements that match the original specifications. Using incorrect or low-quality parts can cause long-term damage to the system, leading to costly repairs. Always refer to the system’s manual or detailed diagrams to ensure the proper fit and compatibility of each part.

Understanding Retractable Mechanism Systems and Troubleshooting

In many modern systems involving retractable components, precise synchronization of different mechanical elements is crucial for optimal performance. These systems are used in various applications, such as mobile homes, trailers, and industrial machinery, and their effective operation depends on the seamless interaction of numerous parts. Identifying issues and understanding how the system works allows for better maintenance and quicker repairs.

Common Problems in Retractable Mechanisms

Over time, mechanical systems designed for extending and retracting can face several issues, from motor failure to misalignment of tracks. One of the most frequent problems is wear on the moving parts, which can cause reduced performance or complete malfunction. Additionally, electrical or control system faults may result in erratic movement or the inability to retract or extend fully. Identifying these issues early on can prevent further damage and ensure smooth operation.

Identifying Key Components in Mechanical Systems

Retractable systems comprise several key components, each of which plays a vital role in the system’s functionality. These include motors, actuators, tracks, rollers, and control units. Understanding each component’s role allows for a better grasp of how the system operates and can guide users when troubleshooting or performing maintenance. If a specific part is damaged or malfunctioning, knowing its function can help in identifying the root cause of the problem.

How to Read Mechanical System Illustrations

Using detailed illustrations of the system can simplify the troubleshooting process. These visuals represent the parts and their connections, providing a clearer understanding of how the system works. By reviewing these drawings, users can quickly locate each component and understand its relationship with other parts. This knowledge can be crucial when diagnosing issues, replacing components, or performing maintenance.

Step-by-Step Guide to Repairs

When facing issues with a retractable system, having a clear, step-by-step repair guide can save time and effort. Start by identifying the problem through visual inspection or diagnostic tools. Once the issue is found, refer to the system’s diagram for guidance on disassembling and reassembling the components. Ensure you use the correct tools and replacement parts for a successful fix. Regularly maintaining the system by cleaning, lubricating, and inspecting key components will help prolong its lifespan and prevent future malfunctions.