Maintaining your lawnmower or garden machinery requires a clear understanding of its internal structure. Knowing how each component fits together ensures smoother operation and helps avoid costly repairs. This section will guide you through the essentials of your equipment’s build, focusing on how to identify and troubleshoot various parts effectively.

Familiarizing yourself with the layout of the machine’s elements can significantly improve your ability to handle issues as they arise. By recognizing key components, you gain the confidence to perform routine maintenance or make informed decisions when replacements are needed.

Regular inspection and care of the machinery can enhance its longevity, reduce the risk of sudden failures, and ensure that it continues performing efficiently throughout the year. In the following sections, you will learn how to navigate the different systems that contribute to the functionality of the engine.

Understanding the Machine’s Components

Every machine is composed of various key elements that work together to ensure optimal performance. By understanding the layout of these components, users can improve their maintenance practices and troubleshoot issues more effectively. Each part plays a vital role, from the engine system to the transmission, ensuring the device operates as expected.

Key Elements of the Equipment

One of the first steps in understanding the machine is familiarizing yourself with its core components. This includes the engine, drive system, and control mechanisms. By knowing where each piece fits into the system, it becomes easier to diagnose problems and perform necessary repairs.

Efficient Maintenance Practices

Regular inspection and upkeep are essential for ensuring the longevity of the equipment. Knowing how to check the individual components for wear and tear helps prevent major breakdowns. Simple actions like lubricating moving parts or tightening loose connections can extend the machine’s lifespan and keep it running smoothly.

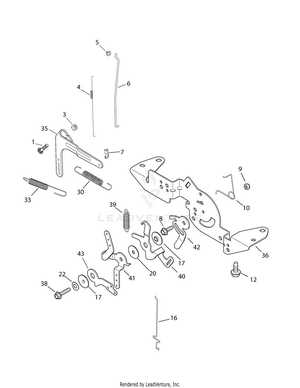

How to Read the Components Layout

Understanding how to interpret a machine’s component layout is crucial for proper maintenance and repair. These visual guides provide a clear representation of where each part fits within the overall structure, making it easier to identify what needs attention. Familiarity with these charts can help in diagnosing problems quickly and ensuring that repairs are made accurately.

When reading the layout, start by recognizing the main sections of the machine. These typically include the engine, transmission, and control elements. Each part is labeled with numbers or codes, which can then be cross-referenced with the manual or parts list to ensure you are addressing the correct item. Paying attention to the positioning of these components allows for a more efficient and informed approach to maintenance and troubleshooting.

Common Repairs and Replacements for SLTX 1050

Routine maintenance is essential for ensuring smooth operation and preventing breakdowns. Several components within the machinery may need regular attention or replacement after extended use. Knowing which parts are most susceptible to wear can help you address issues promptly and keep your equipment running efficiently.

Here are some common repairs and replacements that may be necessary:

- Drive Belt Replacement: Over time, the drive belt can wear out or become damaged, affecting the power transfer to the wheels. Replacing it regularly can prevent unexpected failures.

- Air Filter Cleaning: A clogged air filter reduces engine efficiency and may cause overheating. Regular cleaning or replacing the filter helps maintain optimal engine performance.

- Battery Maintenance: The battery can lose its charge or become corroded. Ensuring it is properly charged and maintaining clean connections extends its lifespan.

- Blade Sharpening: Dull blades can affect cutting efficiency and damage the lawn. Regular sharpening ensures the mower operates at its best.

By keeping an eye on these frequently replaced items, you can avoid unnecessary downtime and ensure that your machine stays in top condition. Always refer to the manufacturer’s guidelines for specific maintenance schedules and procedures to follow.