Proper knowledge of your boat’s engine and its individual components is crucial for efficient maintenance and smooth operation. Identifying and understanding each part allows boat owners to tackle repairs, improve performance, and extend the lifespan of their vessels.

One of the most effective ways to gain insight into the engine’s design and functionality is by studying its detailed layout. With the right resources, it’s possible to recognize the role of each element and how they work together. This helps in identifying potential issues early and addressing them before they lead to serious damage.

In this section, we will explore how to read and utilize a detailed engine blueprint, highlighting common issues and tips for replacing faulty elements. Whether you’re a seasoned technician or a boat owner handling maintenance yourself, this guide will provide valuable information for ensuring your engine runs smoothly.

Understanding Volvo Penta 5.0 GXI Components

Every marine engine is a complex assembly of interconnected elements, each contributing to its overall functionality. To ensure optimal performance, it’s essential to familiarize yourself with the individual components that work together to keep the engine running smoothly. Understanding the various sections of the engine can also help identify potential issues, making repairs and maintenance much more manageable.

Key Engine Sections

The engine is made up of several key sections, each with specific functions. The power unit, for example, includes the block and cylinder heads, which are responsible for converting fuel into power. The fuel system, exhaust system, and cooling system are equally crucial in maintaining engine efficiency and preventing overheating or blockages. Understanding each system’s role ensures that you can spot issues before they become significant problems.

Critical Components and Their Functions

Among the most important parts are the crankshaft, pistons, and camshaft, which facilitate the engine’s movement and fuel combustion. Other components like the ignition system, fuel injectors, and sensors play vital roles in regulating engine performance, making them essential for reliable operation. A deeper understanding of these elements will help you spot signs of wear or malfunction, allowing for timely intervention and maintenance.

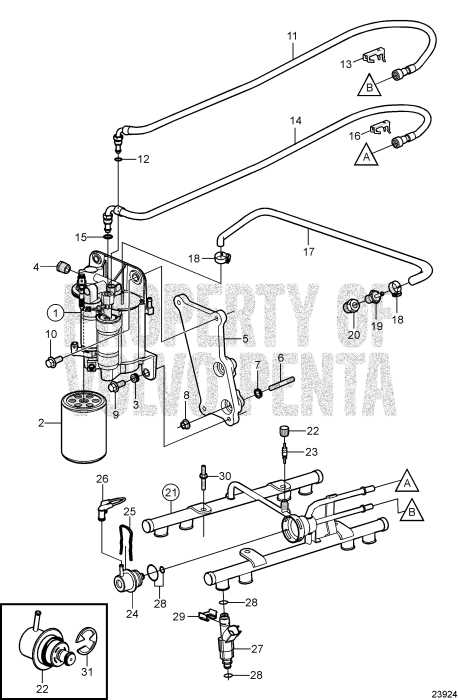

How to Use the Parts Diagram Effectively

Understanding an engine’s internal structure and identifying its components is a critical step in maintaining or repairing any marine engine. A detailed layout can serve as a valuable guide, helping to pinpoint each piece’s role and facilitating troubleshooting. By using these visual references, you can approach repairs with confidence and precision.

Step-by-Step Reference

To make the most of a detailed blueprint, begin by familiarizing yourself with its organization. Typically, the diagram will group parts into logical sections, such as the fuel system, cooling components, and exhaust elements. Start by identifying the larger systems, then drill down to locate smaller components. This will help you understand the overall flow of operations and isolate potential issues.

Common Troubleshooting with Visual References

One of the most effective ways to use a schematic is for troubleshooting. When you notice a problem in engine performance, the diagram allows you to trace the issue back to its source. Whether it’s a malfunctioning part or a worn-out component, identifying the specific part in the visual guide enables faster diagnosis and helps you take the necessary steps to resolve the issue.

Common Issues and Replacement Parts for Volvo Penta

Even the most reliable marine engines can experience issues over time due to wear and tear or environmental factors. Identifying common problems early can save both time and money. Regular maintenance and timely replacements are essential to keep the engine running smoothly and efficiently.

Frequent Problems Encountered

Here are some of the most common issues faced by marine engines:

- Overheating: This often occurs due to a malfunctioning cooling system or a blocked intake. Insufficient water flow can cause significant engine damage if not addressed promptly.

- Fuel System Failures: Issues such as clogged fuel injectors, damaged fuel pumps, or degraded fuel lines can hinder proper combustion and engine performance.

- Exhaust System Blockages: A buildup of debris or corrosion in the exhaust can restrict engine output and reduce efficiency.

- Ignition Problems: Faulty spark plugs, worn ignition coils, or wiring issues can prevent the engine from starting or cause misfires.

Replacement Components for Optimal Functionality

To resolve these issues, certain components will likely need replacement:

- Thermostat and Water Pump: Essential for regulating engine temperature, these components should be checked regularly for signs of wear.

- Fuel Filters and Injectors: Regular replacement of these components ensures optimal fuel flow and engine efficiency.

- Exhaust Manifold and Hoses: These parts are subject to corrosion and wear, so replacing them when necessary is crucial to avoid blockages.

- Ignition Components: Spark plugs, coils, and cables should be inspected frequently for damage and replaced to maintain reliable starting and performance.