To master the art of creating yarn, it’s essential to understand the intricate mechanisms of the traditional tool that has been used for centuries. Each component plays a vital role in ensuring smooth operation and efficient production of thread. This knowledge is crucial for both beginners and experienced users alike, as it aids in maintaining and troubleshooting the equipment.

When examining this ancient instrument, the design may seem complex, but breaking it down into its key sections reveals how each element contributes to its functionality. Understanding how these pieces work together can enhance both the user experience and the quality of the finished product.

Identifying each section and its role in the spinning process helps users to better navigate its use and resolve any issues that may arise during operation. With a clear comprehension of these components, mastering the tool becomes a more intuitive and rewarding experience.

Understanding the Spinning Wheel Components

The functioning of the traditional yarn-making tool relies on the collaboration of various interconnected elements. Each section, although different in its purpose, contributes to the overall process of converting fiber into thread. Gaining a deeper understanding of these elements can greatly improve both the handling and maintenance of the equipment.

Key Mechanisms and Functions

The main sections of the tool include the drive system, the tensioning components, and the drafting mechanism. Each of these plays a distinct role in managing the fiber, ensuring smooth operation and quality output. The drive system transfers energy, while the tensioning elements control fiber tightness, and the drafting mechanism guides the fibers into uniform strands.

How Components Interact

When put together, these components work seamlessly to transform raw fiber into thread. Understanding how they interact allows the user to identify issues that may arise and to fine-tune the tool for more precise results. Whether adjusting tension or ensuring smooth motion, familiarity with these mechanisms can significantly enhance the crafting process.

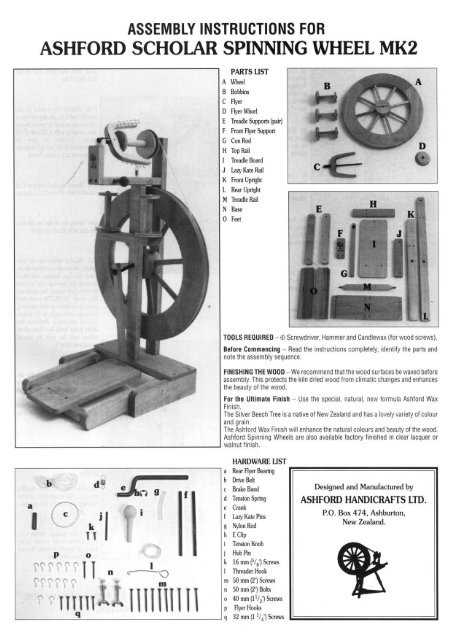

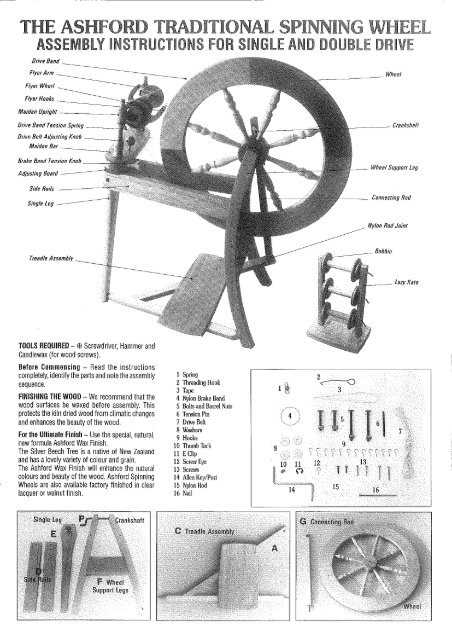

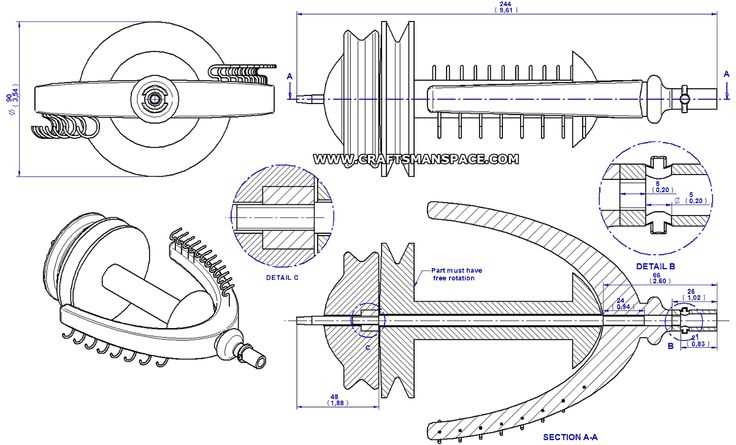

How to Read Spinning Wheel Diagrams

Visual representations of the tool’s structure can provide invaluable insight into its function and maintenance. By analyzing these illustrations, users can better understand the mechanics behind each element, making it easier to operate and troubleshoot the equipment. These drawings often contain labels and annotations that clarify the role of each section, ensuring a clearer comprehension.

Interpreting Key Labels and Symbols

In these visuals, key symbols and labels help distinguish various sections and their specific roles. Identifying these markers allows users to quickly recognize how each component contributes to the overall process. Understanding these symbols is essential when attempting to repair or adjust any part of the system.

Understanding Component Relationships

These diagrams also highlight how different sections interact with one another. Recognizing the relationships between components provides a better grasp of how the machine operates as a whole. This knowledge is crucial when fine-tuning adjustments or solving potential problems in the process.

The Function of Each Spinning Wheel Part

Each section of the traditional yarn-making tool has a distinct function, contributing to the overall efficiency and effectiveness of the process. Understanding how these elements work independently and together is essential for smooth operation and optimal results. A deep knowledge of each part’s role can significantly enhance both the crafting experience and the quality of the final product.

The drive mechanism serves as the heart of the system, transferring energy and enabling the tool to function. It powers the rotation needed to draw fibers together. The tensioning system ensures the right amount of fiber tightness, controlling consistency and preventing breakage. Meanwhile, the drafting system controls the thickness of the yarn, shaping it as it passes through the tool. All of these components must work in harmony to produce a continuous, even thread.

Each individual section plays a crucial role, but their true strength lies in how they interact with each other. For example, adjusting tension can affect the drafting process, influencing the final product’s texture and strength. Understanding these relationships allows for better customization and maintenance of the tool.