When it comes to seated lifting systems, each mechanism and element plays a crucial role in ensuring smooth operation. From the mechanical framework to the control features, understanding how everything works together is essential for effective use and maintenance. This guide explores the essential components that contribute to the overall functionality and provides insight into how they interconnect to create a seamless experience for users.

Key Elements in the Reclining System

Every reclining system consists of several fundamental components, each serving a specific purpose. These pieces work in unison to facilitate movement and adjustability.

- Base Frame: The sturdy foundation that supports all other elements, providing structural integrity.

- Motor and Actuator: The driving forces behind the reclining and lifting motions, controlled by electronic systems.

- Control Panel: The interface that allows users to operate and fine-tune movements, often equipped with buttons or switches for easy access.

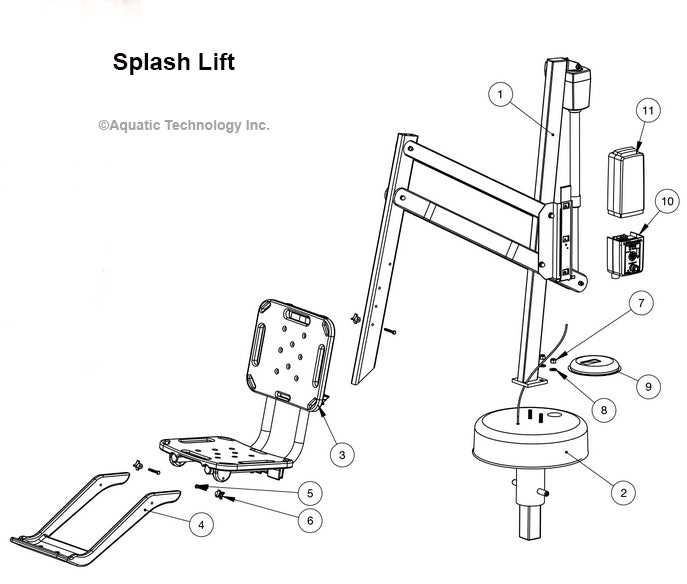

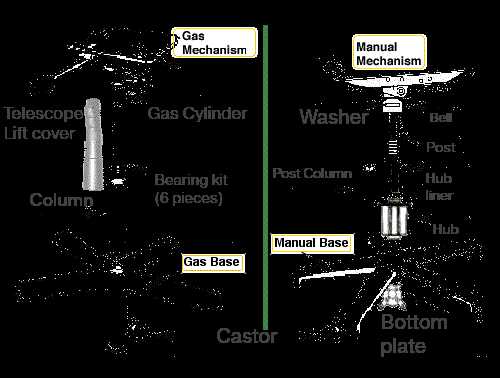

Movement and Support Mechanisms

The support structure includes various systems designed to enable smooth transitions from seated to elevated positions. Understanding their roles can help with diagnosing issues and ensuring that everything functions correctly.

- Hydraulic or Pneumatic Systems: Some systems use fluid or air pressure to assist in shifting positions, offering quiet and efficient operation.

- Linkage System: A set of mechanical arms that connect the base to the upper frame, transferring motion and supporting weight distribution.

Maintenance and Troubleshooting

Over time, components may wear out or malfunction, causing disruptions in performance. Knowing how to troubleshoot these issues can extend the lifespan of your system and ensure continuous comfort.

- Check for Obstructions: Inspecting the area around moving parts for debris or blockages can resolve many issues related to limited mobility.

- Test the Controls: If the system fails to respond, ensure that the control panel is functioning and that there is no electrical issue.

- Examine Wiring: Faulty connections can interfere with proper functionality, so check the wires regularly for wear and tear.

Understanding Reclining System Mechanics and Key Components

In any mechanical seating system designed for assisted elevation, multiple interconnected elements work together to facilitate smooth operation. The synergy between the structural components, electrical systems, and control mechanisms ensures comfort and functionality. In this section, we will break down how these systems collaborate and the specific parts that make them function efficiently.

Core Components of the Mechanism

Several key elements contribute to the seamless movement of the system. These components are designed to support various motions, from reclining to lifting, and ensure optimal performance.

- Base Structure: The foundation that provides support for all other elements, ensuring stability.

- Power Unit: The motor or actuator that enables the movement, providing the necessary force to adjust positions.

- User Interface: The controls used by the user to operate the system, which could be wired or wireless for convenience.

How Movement and Controls Operate Together

The movement of the system relies on the smooth interaction of several parts, with each one supporting a specific function. The power unit is responsible for generating the movement, while the support and linkage structures allow the system to function correctly by transferring motion.

- Hydraulic or Pneumatic Systems: Fluid- or air-based mechanisms can facilitate effortless transitions, often used in high-end models.

- Linkage Mechanism: This system connects all the moving parts, transferring force from the power unit to the desired position.

Wiring and Troubleshooting

The electrical components that power the system are essential for proper operation. It’s important to understand how the wiring and connections function, as well as how to troubleshoot common issues.

- Wiring Integrity: Ensure that the wiring is properly connected and free of damage to prevent malfunctions.

- Control System Issues: If the system fails to respond, check for faults in the control panel or wiring connections.

- Mechanical Wear: Over time, parts such as motors and linkages can wear out, requiring inspection and potential replacement.