Maintaining your lawn equipment is crucial for ensuring its longevity and efficiency. Understanding the layout of essential components can help identify problems early and prevent costly repairs. With proper knowledge, you can easily locate and replace any faulty parts on your mower. This guide will assist you in navigating through various sections and components of your equipment to make the process smoother.

Each machine comes with an intricate system of parts that work together to provide optimal performance. Recognizing each component’s function and knowing how to access them can make a significant difference when troubleshooting or performing routine maintenance. Whether you’re a seasoned professional or a first-time user, this guide offers clear insights into keeping your lawn mower in top condition.

Understanding the John Deere X300R Parts

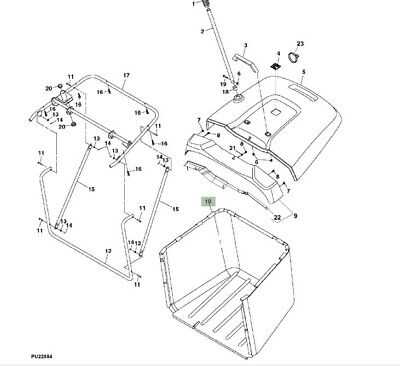

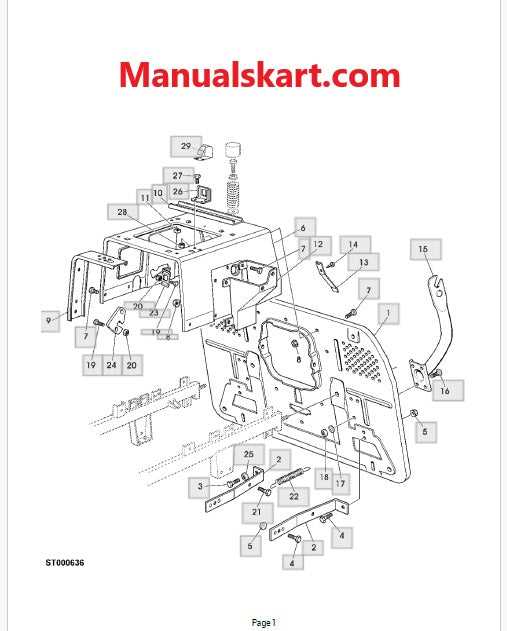

Every lawn mower consists of multiple interconnected components that serve specific functions. A clear understanding of these parts is essential for efficient maintenance and troubleshooting. By knowing how each part interacts with the others, users can easily identify issues and determine the best course of action for repair or replacement. This section will guide you through the key elements of the machine, providing clarity on their roles and how they contribute to the mower’s overall performance.

Among the various components, some are responsible for power transmission, while others handle cutting mechanisms or offer support for the mower’s structure. Each of these plays a vital role in ensuring smooth operation. For instance, the engine components drive power through belts and gears, while the blade system ensures a clean and precise cut. Understanding how these parts work together helps in diagnosing problems and preventing wear or damage to the machine.

How to Read the Parts Diagram

Interpreting a visual representation of machine components can be challenging, especially when it involves various intricate parts. However, understanding how to read these schematics is crucial for identifying and locating each element. A clear guide to reading these visual layouts can help simplify repairs, replacements, and maintenance tasks.

To effectively read such illustrations, follow these essential steps:

- Familiarize yourself with the symbols: Different symbols represent various components such as bolts, belts, or motors. Make sure to identify each before attempting to understand the layout.

- Understand the part numbering system: Components are usually labeled with a unique number. This allows you to quickly reference the part in a list or order it for replacement.

- Follow the flow: The layout often shows the relationship between parts. Pay attention to how the components connect and the direction of operation, which can help in diagnosing issues.

- Check the key or legend: The key provides explanations for symbols, lines, and numbers used in the diagram. Always consult it to avoid confusion.

By mastering these steps, you’ll be able to navigate the schematics confidently and efficiently, streamlining the process of identifying and fixing issues with the machine.

Common Issues and Replacements for X300R

Every piece of equipment undergoes wear and tear over time, leading to potential malfunctions. Understanding common issues and knowing how to replace worn-out components ensures smooth operation and extends the machine’s life. Whether it’s a problem with the engine, drive system, or cutting blades, early detection and timely replacement can prevent further damage.

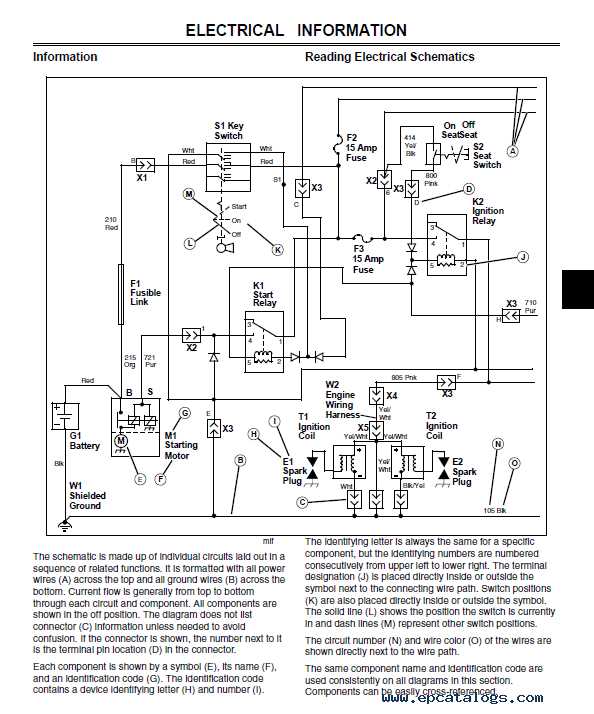

Engine and Power Issues

One of the most common problems involves engine performance. Over time, components like the spark plug, fuel filter, or air filter may become clogged or damaged, causing the engine to run inefficiently or fail to start. Replacing these parts with high-quality, compatible replacements is essential for restoring the engine’s performance. Regular maintenance, such as cleaning the air filter and changing the spark plug, can help prevent these issues from occurring.

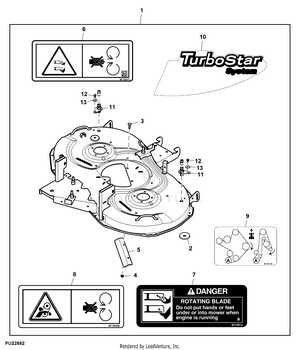

Cutting System and Blade Wear

The cutting system is another area prone to wear. Blades can become dull or damaged, leading to uneven cuts and reduced efficiency. If you notice the blades not cutting properly, it’s essential to inspect them for cracks or excessive wear. Replacing the blades or sharpening them can restore optimal performance. Additionally, ensuring that the belt and pulleys connected to the cutting mechanism are in good condition will prevent unnecessary strain on the engine.