Understanding the components of your tractor’s control system is essential for proper maintenance and smooth operation. This system ensures that all parts work in unison, providing accurate handling and maneuverability. Knowledge of how each element functions can help prevent wear and tear, saving both time and money in repairs.

The tractor’s control assembly consists of multiple elements, each playing a vital role in the overall functionality. From the primary connections to the secondary linkages, it’s crucial to be familiar with the specific parts that contribute to its movement. Regular inspection and identification of potential issues can lead to timely solutions and prevent costly breakdowns.

In this guide, we will explore how these parts interact, common issues that arise, and how to manage replacements effectively. A clear understanding of each section can lead to improved tractor performance and longevity, ensuring that your equipment remains in optimal condition for years to come.

Understanding Tractor Control System Components

Every tractor features a system that governs its movement, ensuring precise direction and stable operation. The components of this system work together to allow the operator to control the machine with ease. Understanding how these elements interact is key to keeping the equipment functional and efficient.

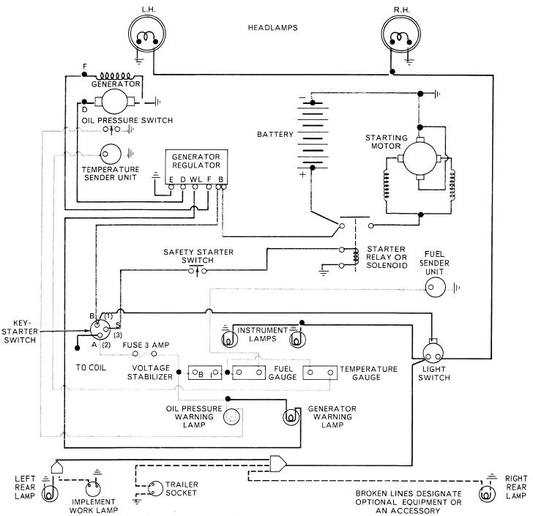

The core elements of this system include several interconnected rods, linkages, and gears. These components are designed to facilitate smooth transitions between turning and straight-line movement, while maintaining the overall integrity of the tractor’s handling. Each part must be in optimal condition to avoid issues such as loss of responsiveness or poor alignment.

When inspecting the system, it’s important to focus on the key elements that contribute to the smooth functioning of the tractor. Knowing where potential wear can occur and recognizing the signs of malfunction will allow for early intervention and the preservation of the vehicle’s long-term performance.

Common Issues with Control System Components

Like any mechanical system, the control mechanism in tractors is prone to wear and tear over time. Several factors can contribute to malfunctions or a decrease in performance, affecting the machine’s handling and maneuverability. Identifying and addressing these issues early can help prevent more serious damage and costly repairs.

One common problem is the loosening of connections between key elements, such as linkages and rods. Over time, vibrations and constant use can cause these connections to weaken, leading to imprecise movement or excessive play in the system. Worn-out bushings and corroded components are also frequent culprits that lead to poor alignment and reduced responsiveness.

Another issue that frequently arises is the accumulation of dirt and debris within the system. Dust, mud, and moisture can get trapped in various components, leading to friction and premature wear. Regular cleaning and lubrication are essential to prevent this buildup. Leaks in hydraulic systems are also a common issue, which can significantly affect performance if left unaddressed.

How to Replace Tractor Control System Components

Replacing worn or damaged components in a tractor’s control system requires attention to detail and the right tools. The process ensures that the machine will continue to function smoothly, improving its handling and responsiveness. Proper replacement not only restores performance but also extends the life of the equipment.

Before starting, it’s essential to safely raise the tractor and secure it on a stable surface. Begin by inspecting the system to identify the specific components that need replacement, such as worn linkages or damaged rods. Remove any parts that are obstructing access to the affected areas. Using the appropriate tools, such as wrenches or hydraulic jacks, carefully detach the old components while keeping track of the order and orientation of each part.

Once the damaged components are removed, install the new ones by following the reverse order of removal. Ensure that all connections are tight and properly aligned. After installation, check the system for proper movement and make necessary adjustments. Finally, test the tractor to confirm that the control system is functioning smoothly and without any issues.