Every machine is made up of several key elements that work together to deliver performance. Understanding how these components interact can greatly improve your ability to troubleshoot and maintain the device. Knowing where each piece fits and how it functions can save time, reduce repair costs, and enhance longevity.

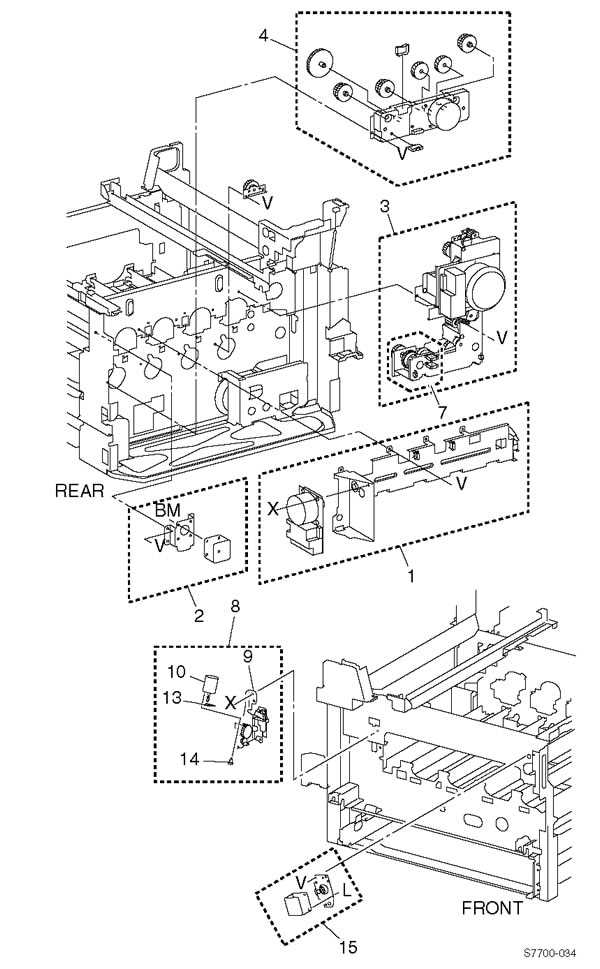

Knowing the layout of internal components is crucial for both simple maintenance and complex repairs. Recognizing each part’s role can also help you identify malfunctions early. Having a clear picture of how everything connects will enable you to address issues promptly, whether it’s replacing a malfunctioning element or performing regular checks.

By studying the detailed structure and function of your equipment, you can confidently handle maintenance tasks. Being prepared with this knowledge ensures you’re never caught off guard and can keep your device running smoothly for years to come.

Understanding Key Components of Brother Printers

Every device contains several integral elements that contribute to its overall function. Understanding these elements helps in recognizing how they work together to perform complex tasks. Familiarity with the internal structure ensures more efficient troubleshooting, repair, and regular upkeep.

Main Internal Functions

The core of any machine lies in its main components, which include the motor, rollers, and sensors. These elements work in harmony to manage tasks such as movement, paper handling, and input detection. Without them, the system would be unable to process documents effectively.

Supporting Components and Their Roles

Alongside the major components are the supporting units, such as the control board, power supply, and connection ports. These play a crucial role in ensuring smooth operation by managing power flow, executing commands, and establishing communication between different parts of the system.

How to Identify Printer Parts Easily

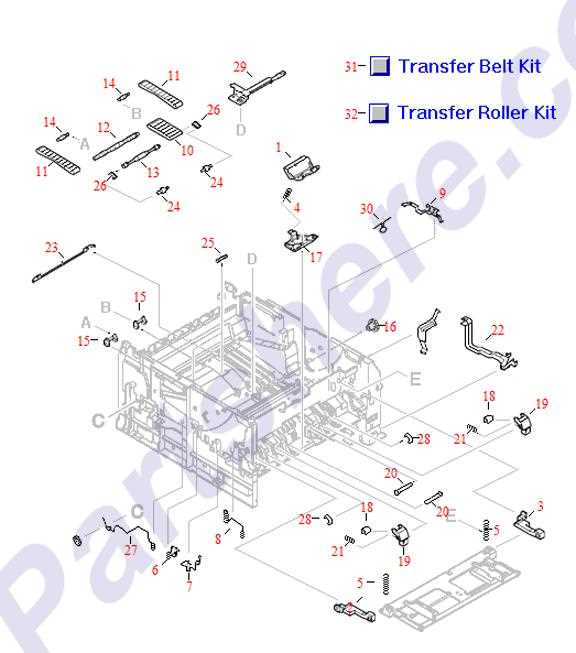

Identifying the components within your device is an essential skill for performing maintenance or troubleshooting. Being able to quickly recognize each element can save you time and effort when dealing with issues. With the right approach, you can easily determine which part needs attention.

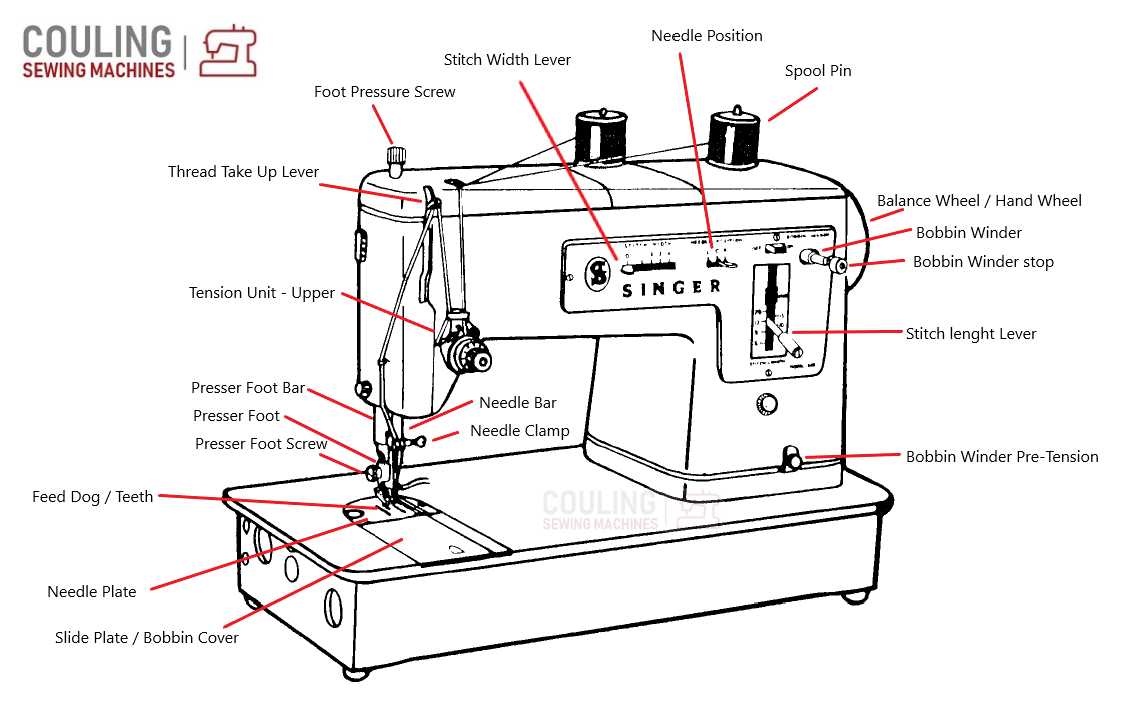

Start with the External Elements

The first step in identifying a malfunctioning element is to inspect the exterior. Common external parts include trays, buttons, and display screens. These components are easy to spot and serve as the interface between the machine and the user, providing a quick way to understand its status and functionality.

Look Inside for Internal Components

Once the exterior is examined, it’s time to focus on the internal workings. Key internal components such as the motor, sensors, and rollers can usually be identified by their shape, size, and location within the device. Referencing a guide or using a labeled chart can be extremely helpful in pinpointing each part’s function.

Common Issues and Part Replacement Tips

Even the most reliable devices can experience issues over time. Identifying common problems and knowing how to replace faulty elements is crucial to maintaining efficient operation. This section highlights frequent malfunctions and offers guidance on how to handle replacements effectively.

One common issue is paper jams, often caused by worn-out rollers or misaligned components. If you encounter this problem, inspect the rollers for damage and clean them thoroughly. If the problem persists, replacing the rollers might be necessary. Additionally, components like the control board can fail due to electrical issues, requiring replacement to restore functionality.

Another issue involves poor-quality output, which could be linked to a damaged imaging unit or toner cartridge. Replacing these elements is relatively straightforward, but ensuring proper installation is key to resolving the problem. Always check for any signs of leakage or wear before replacing.