Every modern home relies on an intricate system of components that ensure smooth operation and secure access. This system comprises various elements that work in harmony to facilitate easy and reliable movement. Understanding how these components interact is crucial for maintenance and troubleshooting. With the right knowledge, you can identify potential issues and enhance the overall functionality of the system.

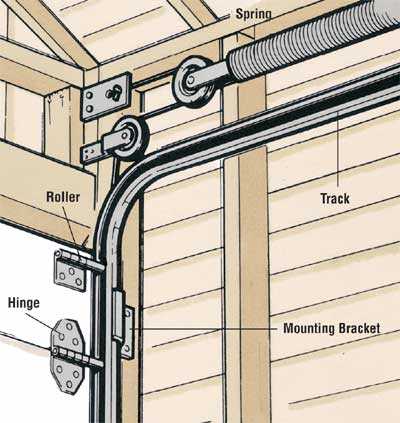

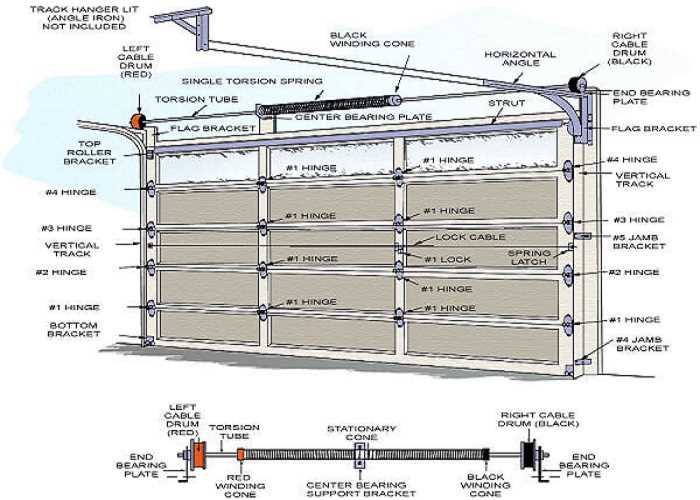

Visual representations of these elements provide a clear view of their arrangement, making it easier to grasp their roles and how they contribute to the efficient working of the system. Whether you’re a first-time homeowner or an experienced technician, a thorough understanding of these mechanisms can save you time and effort when diagnosing problems.

In this guide, we will explore the essential components involved in the operation of an entry system, providing insights into their structure, function, and the typical challenges that may arise over time.

Key Components of a Garage Door

When it comes to automatic entry systems, several essential elements come together to ensure smooth operation. Each component plays a unique role in providing security, convenience, and functionality. These systems are complex, yet understanding the key components is crucial for both maintenance and troubleshooting. Below are some of the main components that work in tandem to ensure reliable performance.

Mechanisms for Smooth Operation

The following are vital components that contribute to the efficient movement of the system:

- Tracks – These guide the movement of the system, ensuring it moves up and down without deviation.

- Springs – These counterbalance the weight, making the lifting and lowering process easier and safer.

- Rollers – These facilitate smooth movement along the tracks, reducing friction and wear over time.

- Motor – The driving force that powers the entire system, enabling automatic opening and closing.

Supporting Structural Elements

- Frame – This provides the structural integrity to hold all components in place.

- Cables – These are responsible for the lifting and lowering actions, working in tandem with the springs for smooth movement.

- Weather seals – These prevent drafts and debris from entering the system, contributing to energy efficiency and cleanliness.

How to Read a Garage Door Diagram

Understanding visual representations of entry systems can be extremely useful when it comes to repairs, maintenance, or installation. These schematics offer a clear and concise way to visualize the arrangement of various elements and how they interact. Being able to interpret these images helps identify issues and understand the relationships between different components, making it easier to perform tasks or troubleshoot problems effectively.

When reading a schematic, it’s important to focus on key features that indicate the function and positioning of each component. Elements are typically represented in simplified forms, with lines, symbols, and labels showing their orientation and interconnections. Pay close attention to the following:

- Symbols – These represent specific elements, such as rollers, springs, or motors. Familiarizing yourself with the standard symbols used can save time and reduce confusion.

- Lines – Lines usually indicate connections between components. Solid lines often represent structural connections, while dashed lines may show movements or other dynamic elements.

- Labels – Clear labels help identify each part, including its name and sometimes its dimensions, function, or specific features.

By carefully studying the diagram and following these basic principles, you can quickly gain a better understanding of how the system functions as a whole. This knowledge is invaluable for proper care and efficient repair work.

Common Issues with Garage Door Parts

Over time, various elements of an entry system can experience wear and tear, leading to common issues that affect performance. Recognizing these problems early on can help prevent further damage and costly repairs. In this section, we will explore some of the most frequent challenges faced with the key components that ensure smooth and reliable operation.

Mechanical Failures

Mechanical failures are one of the most common issues encountered. These can range from problems with movement to full malfunctions of the system. The following are typical mechanical problems:

- Broken springs – Over time, tension can cause springs to snap, affecting the ability to lift or lower the system.

- Damaged rollers – Worn-out rollers can cause noisy or uneven movement, making operation less smooth.

- Motor failure – The motor may stop working due to electrical issues, wear, or overheating.

Structural and Alignment Issues

Improper alignment or structural damage can lead to more serious functional problems. These issues often cause the system to operate incorrectly or unevenly. Common concerns include:

- Misaligned tracks – If tracks are bent or shifted out of place, the system may not move smoothly, or it might get stuck.

- Loose components – Loose bolts or fasteners can affect the stability of the structure and cause components to malfunction.

- Worn-out cables – Damaged cables can result in the system becoming imbalanced and prevent proper operation.

Identifying these issues early allows for quicker intervention, improving the longevity and efficiency of the entire setup.