Maintaining and repairing outdoor tools requires a clear understanding of their internal structure and the individual elements that contribute to their functionality. Knowing the layout and connections between different components is essential for ensuring efficient operation and easy troubleshooting. Whether you’re a professional or an enthusiast, having a solid grasp of how parts are organized can save time and reduce errors during repairs.

Detailed visual references are invaluable in this process. They offer an intuitive guide to each part’s location, making it easier to pinpoint issues and identify the correct replacements. With these references, users can gain confidence in their ability to perform maintenance and handle repairs with precision.

Having access to a comprehensive guide that outlines each section’s function allows for greater efficiency when disassembling or reassembling the machine. This knowledge helps avoid unnecessary confusion and contributes to the longevity and optimal performance of the equipment.

Understanding the Equipment’s Components

Familiarizing yourself with the internal structure of your outdoor tool is crucial for proper handling and maintenance. Recognizing how each element fits together and serves a specific function ensures the device operates at its best and helps you address any malfunctions quickly. Knowledge of the individual elements enhances overall efficiency and ease during repairs or replacements.

Each section of the tool is designed with specific tasks in mind. From the power source to the intake and exhaust systems, each piece contributes to the overall performance. By understanding these components, you can identify potential problems early and ensure the proper functioning of the machine.

Having a clear view of the internal setup also aids in troubleshooting. With the right insight into where each part is located and how it interacts with the rest, you’ll be better equipped to perform maintenance and repairs without unnecessary delays or mistakes.

How to Read the Equipment Layout

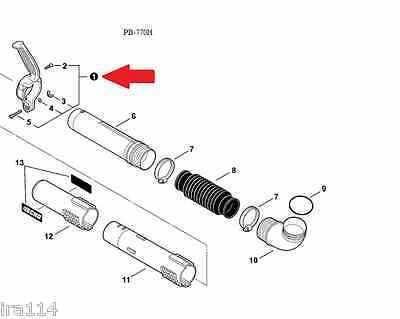

Interpreting visual guides of your outdoor tool’s internal structure is key to understanding its setup and performing repairs. These illustrations provide a comprehensive view of each component’s position, making it easier to identify issues and source replacements. Knowing how to read these references will empower you to tackle maintenance tasks with confidence and precision.

Understanding the Symbols and Labels

The first step in reading these guides is to familiarize yourself with the symbols and labels used. Each component is represented by a unique shape or icon, often accompanied by a number or name. Pay close attention to these markings, as they directly correspond to the physical elements within the tool. This system allows you to match the visual reference with the actual part you need.

Identifying Connections and Assembly

Once you’re familiar with the symbols, focus on how the various components are connected. Lines and arrows are often used to illustrate how different parts interact or fit together. Look for these connections to understand how the tool functions as a whole. This will help you navigate the guide more effectively when reassembling or troubleshooting the device.

Common Issues and Replacement Parts

Every machine, regardless of its design, is susceptible to wear and tear over time. Understanding the typical malfunctions and knowing which components are most likely to need replacing can help you keep your equipment in top condition. Identifying these common issues early on ensures you can address them before they affect the tool’s performance or cause further damage.

One of the most frequent problems with outdoor tools is a clogged or damaged intake system. This can lead to poor performance and reduced efficiency. Another common issue is a malfunctioning fuel system, which can cause difficulty starting the engine or irregular operation. In both cases, knowing which components are vulnerable to damage allows for quick troubleshooting and the timely replacement of the affected parts.

For effective maintenance, it’s important to keep a list of the most commonly needed replacements. These typically include filters, seals, and fuel lines. Keeping these components on hand can prevent downtime and ensure that your equipment remains operational even when parts need to be swapped out.