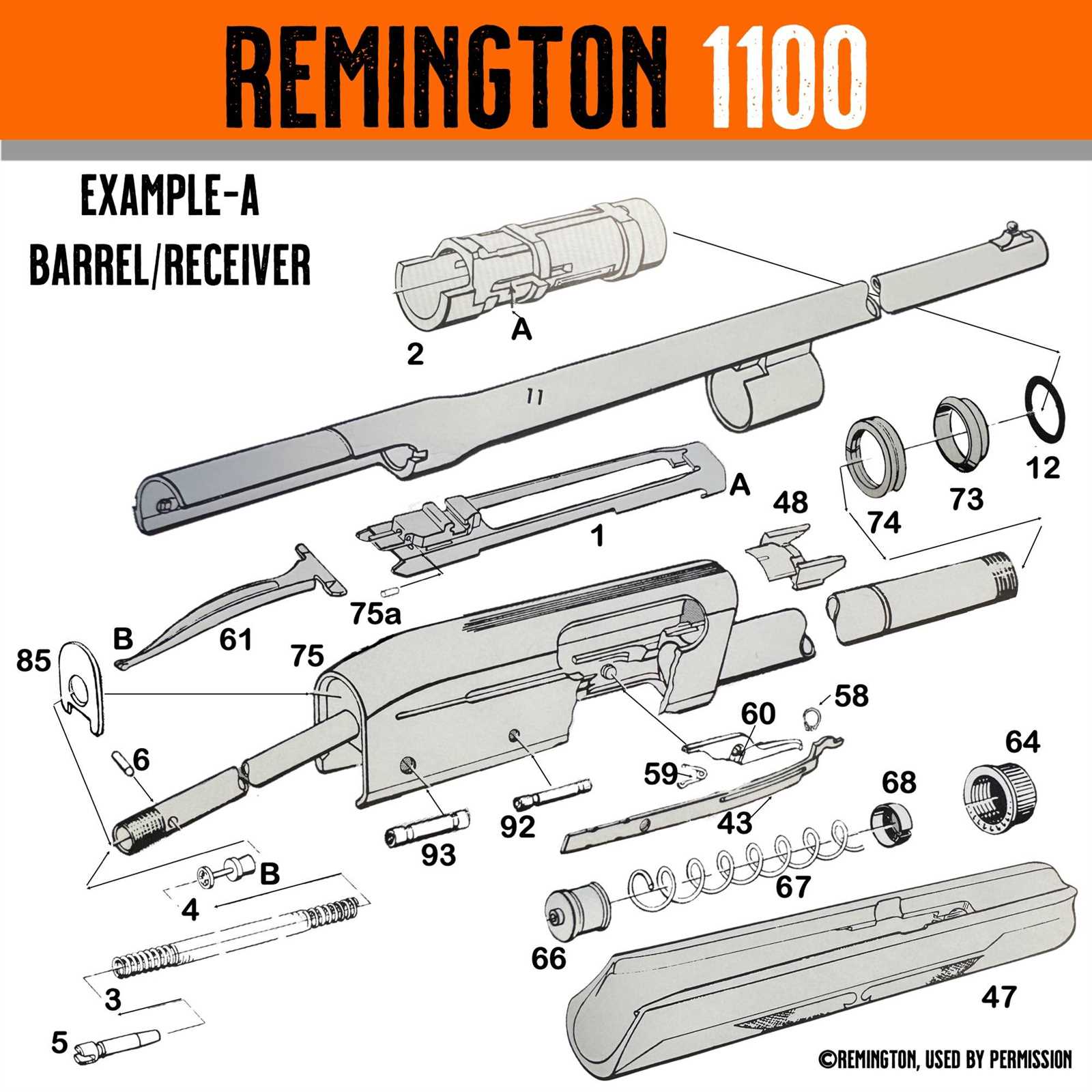

When it comes to maintaining and repairing firearms, understanding the intricate details of their construction is crucial. A clear representation of a firearm’s internal and external components helps enthusiasts, technicians, and owners ensure everything functions optimally. Each part plays a vital role in the overall operation, and a proper guide can significantly ease the troubleshooting process.

Accurate illustrations of the assembly provide a detailed view, assisting with identification and the identification of potential issues. Whether you’re assembling or replacing specific elements, these guides make the process more efficient and less prone to errors.

Knowing where each piece fits and how they interact with one another is essential for a smooth repair or upgrade. This article will explore how these layouts work and what makes them so valuable for firearm maintenance.

Understanding Shotgun Component Layout

A well-constructed firearm relies on the precise arrangement of various components. The successful operation of each mechanism depends on how these elements fit together, working in harmony to ensure efficiency and safety. Understanding the layout of these critical pieces is essential for both regular maintenance and troubleshooting. By familiarizing yourself with how each element interacts, you gain a clearer perspective on what to look for when addressing issues or upgrading your firearm.

The Importance of a Structured Guide

Detailed illustrations of a shotgun’s internal and external systems serve as an invaluable reference. These visual guides help users quickly locate each piece, reducing confusion during maintenance or reassembly. Knowing the exact placement of every component allows for easier identification of wear and tear, which can be crucial in preventing malfunction. Whether dealing with a malfunction or preparing for routine cleaning, such guides provide clarity and confidence in the process.

Component Functionality and Relationships

Each element in a firearm’s design has a specific purpose, and understanding these functions is key to effective use. Components work together in a delicate balance to control the flow of energy and ensure reliable performance. By recognizing how each part contributes to the system, you can identify potential issues more efficiently. This knowledge is invaluable when making decisions about repairs, upgrades, or even custom modifications.

How to Use the Assembly Layout Effectively

Having a clear visual reference for your firearm’s components can make all the difference when it comes to maintenance and repairs. A detailed layout provides a roadmap for identifying each piece and understanding how they interact with one another. To use this resource effectively, it’s important to approach it with a clear purpose, whether for assembly, troubleshooting, or part replacement.

Start by carefully examining the layout to familiarize yourself with the arrangement of internal and external elements. Pay close attention to the positioning of each part in relation to others. This helps in identifying potential areas of concern, such as misalignment or wear. Additionally, these illustrations typically highlight key components that require regular attention, guiding you through common maintenance procedures with precision.

When using the guide for repairs or upgrades, take time to compare the visual reference with the actual components you are working with. This comparison ensures that everything is placed correctly and can help avoid mistakes during reassembly. Whether you’re replacing a worn part or upgrading a specific function, an accurate reference is indispensable for a successful outcome.

Common Issues and Component Replacements

Like any mechanical device, firearms are subject to wear and tear over time. Understanding the typical problems that can arise and knowing which elements to replace is essential for maintaining optimal performance. Common issues often involve malfunctioning components that affect the firearm’s reliability, but with the right knowledge, repairs can be straightforward.

Misfires and ejection failures are among the most frequent problems, often caused by worn-out springs or a misaligned gas system. In these cases, replacing the trigger mechanism or gas piston can resolve the issue. Regular inspection of these components can prevent more serious malfunctions down the line.

Another common issue involves the wear of internal seals and springs, which may cause the firearm to fail to cycle properly. Replacing these elements with high-quality, durable parts is crucial for restoring functionality. Ensuring these components are in top condition helps maintain smooth operation and prevents excessive damage to other internal systems.