When dealing with complex mechanical systems, having a clear visual representation of the internal components is crucial for effective troubleshooting and maintenance. Knowing how each part functions and interacts with the others can save time, prevent errors, and extend the lifespan of the equipment. A well-detailed reference allows both professionals and enthusiasts to ensure smooth operation and quick resolution of issues.

In this guide, we will explore a detailed reference of a specific unit, focusing on its essential elements. This overview will assist you in identifying components, understanding their roles, and providing insights into their proper maintenance. Whether you’re a technician or simply seeking to improve your understanding of the system, this breakdown will be an invaluable resource.

Maintaining the integrity of the system requires more than just knowing what parts are present–it involves understanding how they contribute to overall performance. By familiarizing yourself with the key components, you can ensure that your equipment runs efficiently and reliably.

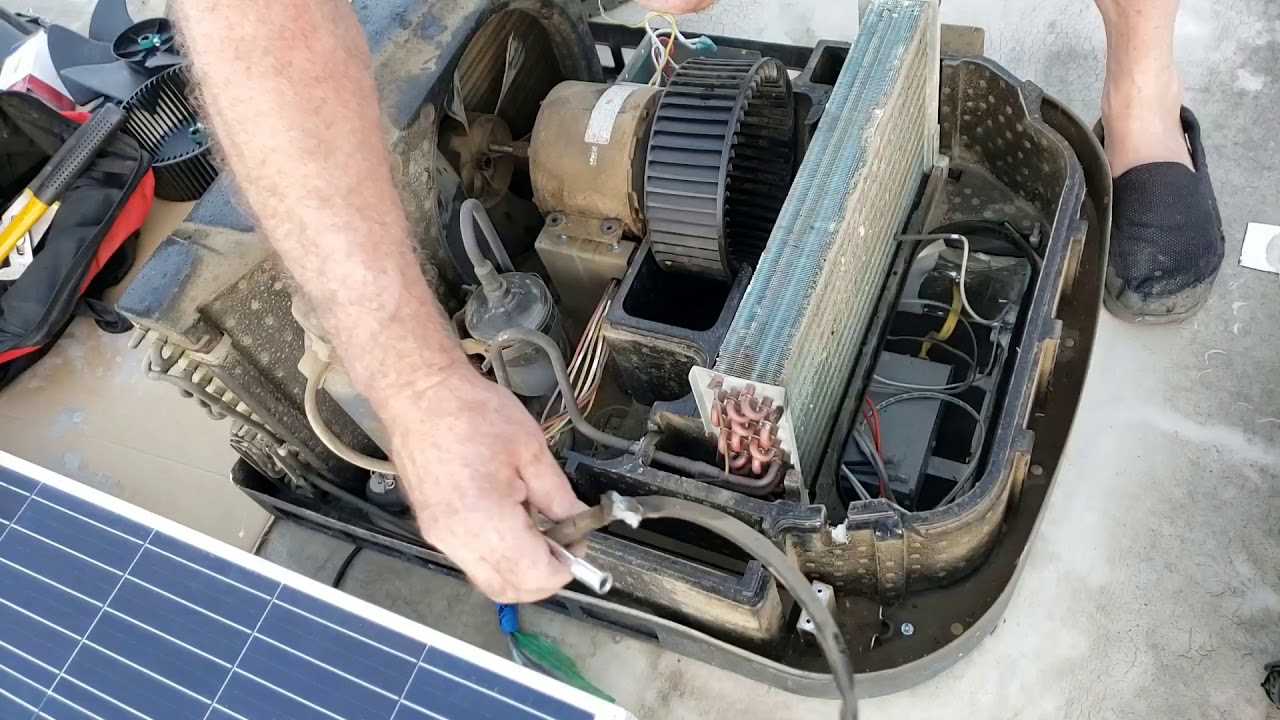

Understanding the System Components

To effectively operate and maintain any mechanical system, it’s essential to understand the individual elements that make it function. Each component plays a crucial role, and without a clear understanding of their interrelationships, troubleshooting and repairs can become unnecessarily complex. Whether you’re working on installation, maintenance, or upgrades, identifying the key pieces ensures a more efficient process.

In the context of this particular model, the various elements work together to ensure optimal performance. These include both mechanical and electrical components, each serving a specific purpose within the larger framework. Understanding how each part contributes to the overall function will help you make informed decisions when performing repairs or adjustments.

Knowing the main components involved gives you the confidence to address issues as they arise. It also helps in recognizing early signs of wear and tear, allowing for preventative measures that can prolong the life of the system. A comprehensive understanding of these elements is the foundation for effective and sustainable operation.

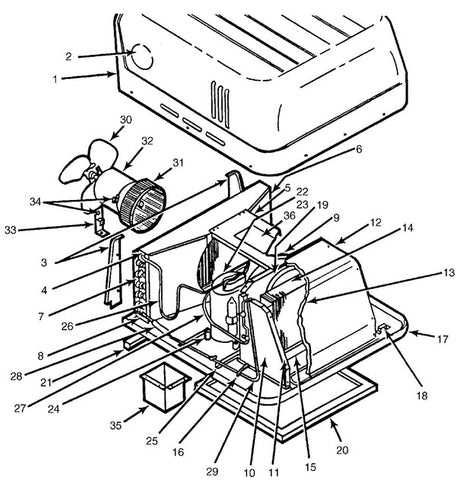

How to Interpret the System Layout

Understanding the layout of a mechanical system can greatly simplify the process of diagnosing and repairing issues. A clear representation of the system’s components allows you to visualize their arrangement and how they interact with one another. By examining this visual reference, you can quickly identify each element and its function within the whole structure.

When interpreting this layout, it’s important to pay attention to the labels and connections shown between each element. Each component will typically be numbered or marked, with lines indicating their relationship to other parts. Recognizing these connections is key to understanding the flow of power, data, or movement within the system, which helps in troubleshooting any faults that may arise.

Moreover, these representations often include helpful annotations that offer insights into each component’s role. These notes can guide you through installation, replacement, or maintenance tasks by explaining the specific requirements or limitations of each element. Becoming familiar with this layout is essential for anyone looking to ensure the proper functioning of the system over time.

Common Issues and Solutions with the System

Like any mechanical unit, issues can arise over time with various components. Identifying these common problems early on can prevent further damage and ensure the system continues to operate smoothly. In this section, we will explore some frequent issues encountered and provide practical solutions to resolve them.

Overheating or Poor Cooling Performance

One of the most common problems with this system is overheating or reduced cooling efficiency. This issue often arises due to insufficient airflow or blocked vents. Inadequate maintenance, such as failing to clean air filters or ducts, can also contribute to poor performance.

| Issue | Possible Cause | Solution |

|---|---|---|

| Overheating | Clogged filters or blocked airflow | Clean filters and ensure proper ventilation |

| Poor Cooling | Low refrigerant levels or malfunctioning fans | Check refrigerant levels, replace malfunctioning components |

Electrical Failures

Electrical malfunctions can occur, especially if connections become loose or components degrade over time. These failures can cause the system to shut down unexpectedly or fail to start properly. Regular inspection and maintenance of the wiring and electrical components are crucial in preventing such issues.

| Issue | Possible Cause | Solution |

|---|---|---|

| Failure to Start | Loose electrical connections or faulty power supply | Inspect and tighten all electrical connections |

| Inconsistent Power | Damaged wires or components | Replace damaged components and check for continuity |

By addressing these common issues promptly and performing routine maintenance, the system can continue to operate effectively and efficiently for years to come.

Maintaining and Replacing Key Components

To ensure a system operates at its best, regular maintenance and timely replacement of crucial elements are essential. Keeping these components in good condition not only improves performance but also helps avoid costly repairs in the future. In this section, we’ll focus on the key components that require attention and the steps involved in their upkeep.

Routine Maintenance Tips

Routine maintenance plays a critical role in extending the lifespan of the system. Neglecting basic upkeep can lead to unnecessary wear and malfunctioning parts. Here are some important tasks to include in your maintenance routine:

- Clean air filters regularly to ensure proper airflow and cooling efficiency.

- Inspect wiring connections to prevent loose or frayed wires from causing electrical issues.

- Lubricate moving parts to reduce friction and prevent excessive wear.

- Check and replace any worn-out seals or gaskets to maintain system integrity.

Replacing Worn or Malfunctioning Components

While maintenance can keep parts in working order, certain components may eventually need to be replaced due to age or wear. Recognizing when it’s time to replace a part is key to avoiding system failure. Common components that require replacement include:

- Cooling fans: If fans become noisy, unresponsive, or stop functioning altogether, replacement is necessary.

- Power supply units: Over time, electrical components may degrade, leading to power issues or system shutdowns.

- Filters and vents: Dirty or clogged filters can reduce efficiency and lead to overheating if not replaced promptly.

By following these guidelines for maintaining and replacing essential components, you can ensure the long-term reliability of the system while avoiding unexpected failures.

Benefits of Accurate Component Identification

Accurately identifying each element in a mechanical system is crucial for efficient troubleshooting, maintenance, and repair. When every part is easily recognizable, it ensures that the right solution is applied at the right time, minimizing downtime and avoiding unnecessary replacement of intact components. Proper identification also helps improve the overall longevity of the system by addressing issues quickly and effectively.

Improved Efficiency in Repairs

One of the main advantages of accurate component identification is the ability to perform repairs more efficiently. Knowing exactly which part needs attention eliminates guesswork, speeding up the process. Technicians can quickly locate faulty components and replace or repair them without wasting time on unnecessary steps.

Cost Savings and Avoiding Mistakes

Proper identification reduces the risk of purchasing the wrong replacement parts, saving both time and money. Incorrectly replacing a component can lead to further damage and additional repair costs. Furthermore, accurate recognition of parts helps ensure that only those truly in need of replacement are addressed, preventing unnecessary expenses.

In summary, accurate component identification not only enhances operational efficiency but also contributes to cost-effective management and prolongs the life of the system.