Small engines are integral to many machines, providing the necessary power for various tasks. Understanding the structure and functionality of these power units is essential for anyone involved in maintenance or repair. Having a clear view of each individual element helps to ensure proper care, quick diagnostics, and effective troubleshooting.

Recognizing the specific roles of each part in the system is crucial. By familiarizing yourself with their positions and connections, you can efficiently address common malfunctions and extend the longevity of the motor. Whether you are performing regular maintenance or need to solve a mechanical issue, knowing how the components interact can save both time and effort.

Accurate identification and replacement of malfunctioning components often rely on a detailed reference guide. A well-organized map of these elements allows users to quickly pinpoint issues, minimize downtime, and avoid unnecessary repairs. This practical approach is valuable for both novice enthusiasts and experienced technicians alike.

Understanding Small Power Unit Components

Every mechanical system operates through the coordinated effort of multiple individual elements. These components work together to generate power and facilitate movement or other tasks. A clear understanding of each element’s role is essential for proper upkeep, troubleshooting, and repair. When you can identify the function and location of each piece, maintaining the entire system becomes a much more manageable process.

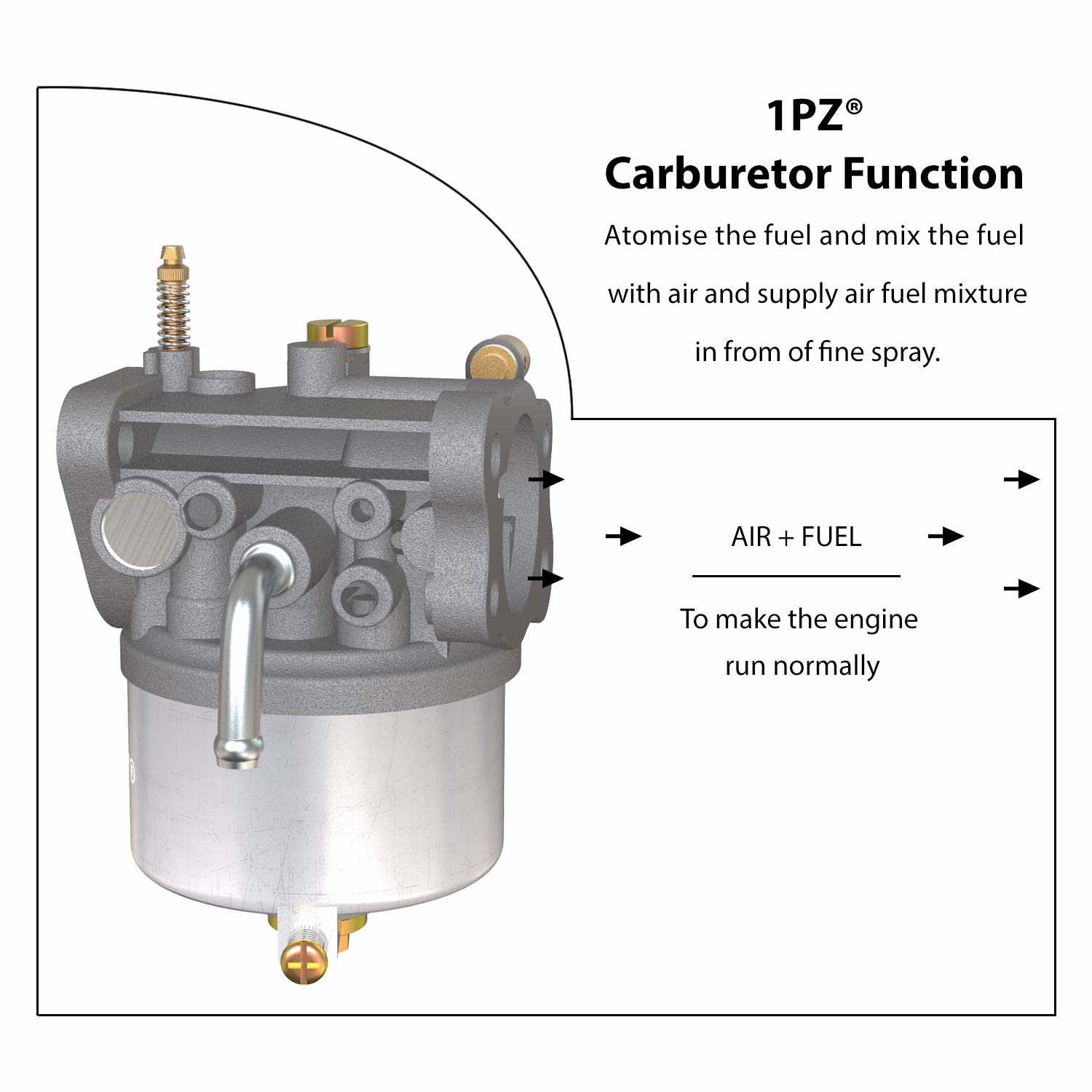

In a small power unit, several key components are critical for optimal performance. These elements include the combustion chamber, fuel delivery system, ignition system, and cooling mechanisms. Each of these parts has a specific job, and failure in any one of them can lead to a breakdown of the entire operation. Understanding their interactions helps to prevent common issues and ensures that the unit runs efficiently.

By learning how each component contributes to the overall function, users can spot early signs of wear or damage. This knowledge allows for more accurate diagnostics and quicker resolution of any problems that may arise. Regular inspection and maintenance of these key elements will not only keep the unit running smoothly but also prolong its lifespan.

Essential Components for Regular Maintenance

To keep any mechanical system running smoothly, certain elements require regular attention and upkeep. Identifying which parts are most vulnerable to wear and tear allows for proactive care and minimizes the risk of sudden breakdowns. Regular inspection of these key components ensures that the entire mechanism operates efficiently over time.

Among the most critical elements are the fuel delivery system, which ensures proper combustion, and the ignition system, which initiates the power cycle. The cooling system also plays a vital role in maintaining optimal temperature levels and preventing overheating. Thorough cleaning and lubrication of moving components like the crankshaft and pistons are also essential for reducing friction and prolonging their lifespan.

Neglecting any of these components can lead to poor performance or even complete failure. Regular checks and timely replacements of worn-out parts ensure a long-lasting and trouble-free experience. Prioritizing these elements during maintenance tasks guarantees that the unit will continue to deliver reliable results when needed the most.

How to Read an Engine Component Map

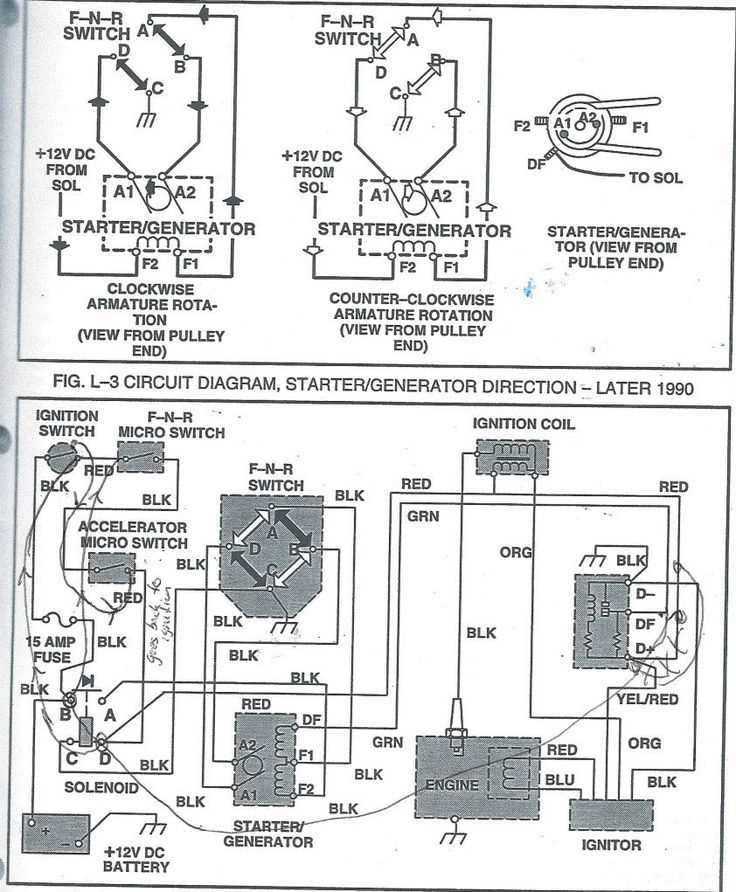

Understanding a mechanical map is essential for anyone looking to maintain or troubleshoot a power unit. These detailed charts provide a visual representation of how each individual element fits within the larger system. By learning to interpret these maps, you can identify components quickly, understand their roles, and pinpoint issues efficiently.

Steps to Interpreting the Map

When first examining the map, begin by familiarizing yourself with the overall layout. Follow these steps for a clear understanding:

- Identify the main sections of the map, which typically represent major systems like fuel, ignition, or cooling.

- Look for labels or numbers that correspond to each component. These identifiers help you find specific parts when referring to a list or manual.

- Study the lines or connections between components. These show how parts interact with each other and help identify potential issues, such as leaks or malfunctions.

Tips for Effective Use

To make the most out of the component map, keep the following tips in mind:

- Use a magnifying glass or zoom tool if the map has small text or intricate details.

- Cross-reference the map with a service manual to get a more thorough understanding of each part’s function.

- Familiarize yourself with common symbols used on the map to avoid confusion.

By following these steps and tips, you’ll be able to decode any component map and gain a deeper understanding of the system’s structure, making maintenance and repairs simpler and more efficient.

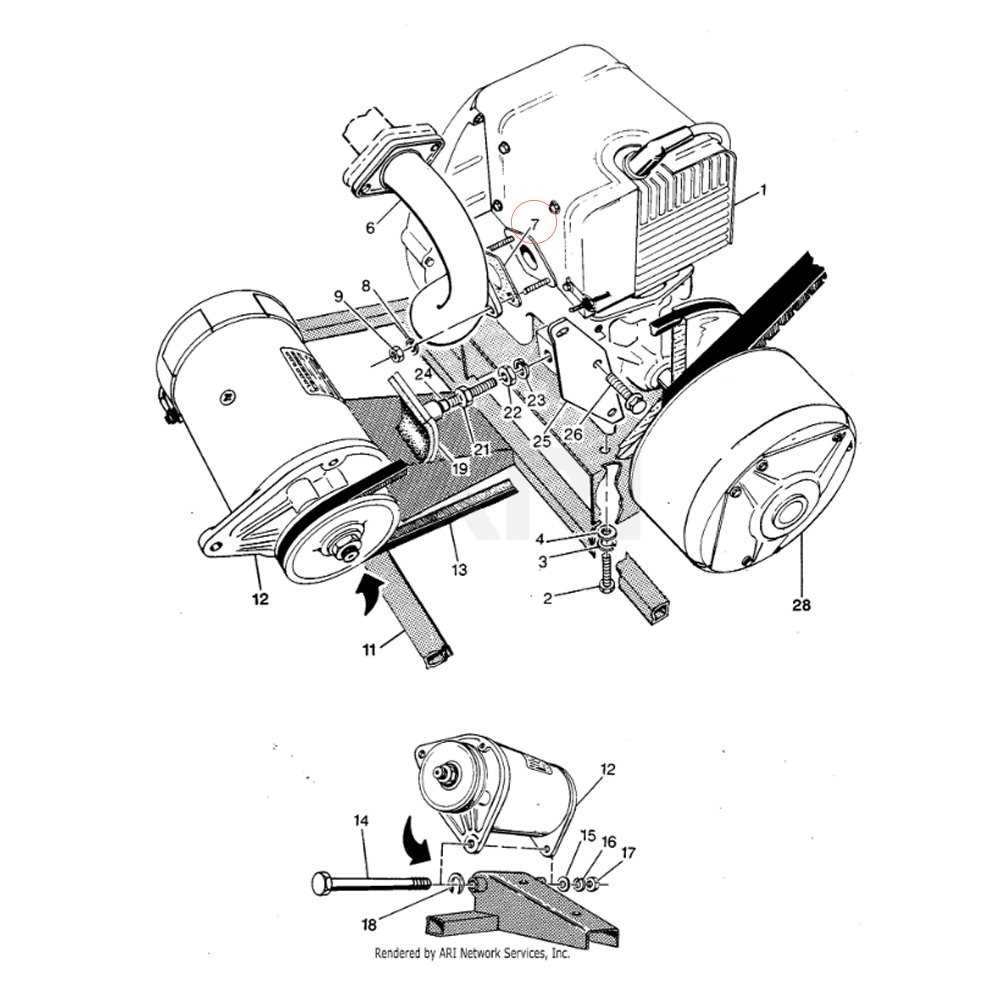

Step-by-Step Guide to Part Identification

Accurately identifying each element within a mechanical system is a crucial skill for anyone involved in maintenance or repair. Proper identification ensures that you can locate issues quickly, choose the right tools, and perform the necessary tasks effectively. This guide will walk you through the process of recognizing key components, helping you understand their functions and how they interact within the system.

Follow these steps to efficiently identify each component:

- Start with the basics: Begin by familiarizing yourself with the system as a whole. Understand the general layout and major sections of the unit.

- Locate key features: Identify larger components first, such as the fuel system, ignition, or exhaust elements. These are usually easier to spot and serve as reference points for smaller parts.

- Check for labels or identifiers: Most systems will have numbers, letters, or symbols near each element. These identifiers are your roadmap to finding the right part in your manual or parts list.

- Follow connections: Observe how components are connected to one another. This will help you understand the flow of energy, fuel, or air throughout the system and identify potential points of failure.

- Cross-reference with a manual: Once you’ve located the parts, refer to the manual or schematic for a more detailed explanation of each component’s role and specifications.

By following this step-by-step approach, you’ll develop a clear understanding of how each element fits into the larger mechanism, making maintenance and repairs more straightforward.

Common Issues with Small Power Units

Like any mechanical system, small power units can encounter a variety of problems over time. Recognizing the signs of these issues early is crucial to ensuring smooth operation and preventing costly repairs. Understanding the most common malfunctions and their causes allows for more efficient troubleshooting and quick resolutions.

Fuel Delivery Problems

One of the most frequent issues with small engines is fuel-related malfunctions. These can stem from clogged filters, dirty carburetors, or improper fuel mixtures. When the fuel system isn’t functioning correctly, the unit may struggle to start, run erratically, or lose power during operation. Regular maintenance, such as cleaning the fuel system and replacing filters, can help prevent these issues.

Ignition System Failures

A faulty ignition system is another common problem that can lead to starting difficulties. Worn spark plugs, damaged wires, or malfunctioning coils can all disrupt the spark needed to ignite the fuel mixture. Symptoms of ignition issues include misfires, backfiring, or the inability to start the unit. Replacing worn parts and ensuring proper connections can restore reliable starting performance.

By staying on top of these common issues and conducting regular maintenance, you can keep your small power unit running at its best and avoid unexpected breakdowns.