When it comes to maintaining outdoor machinery, knowing the essential components and how they fit together is crucial for smooth operation. This guide explores the key elements that contribute to the efficient functioning of your device, helping you identify, maintain, and replace specific parts when needed.

How to Identify Different Parts

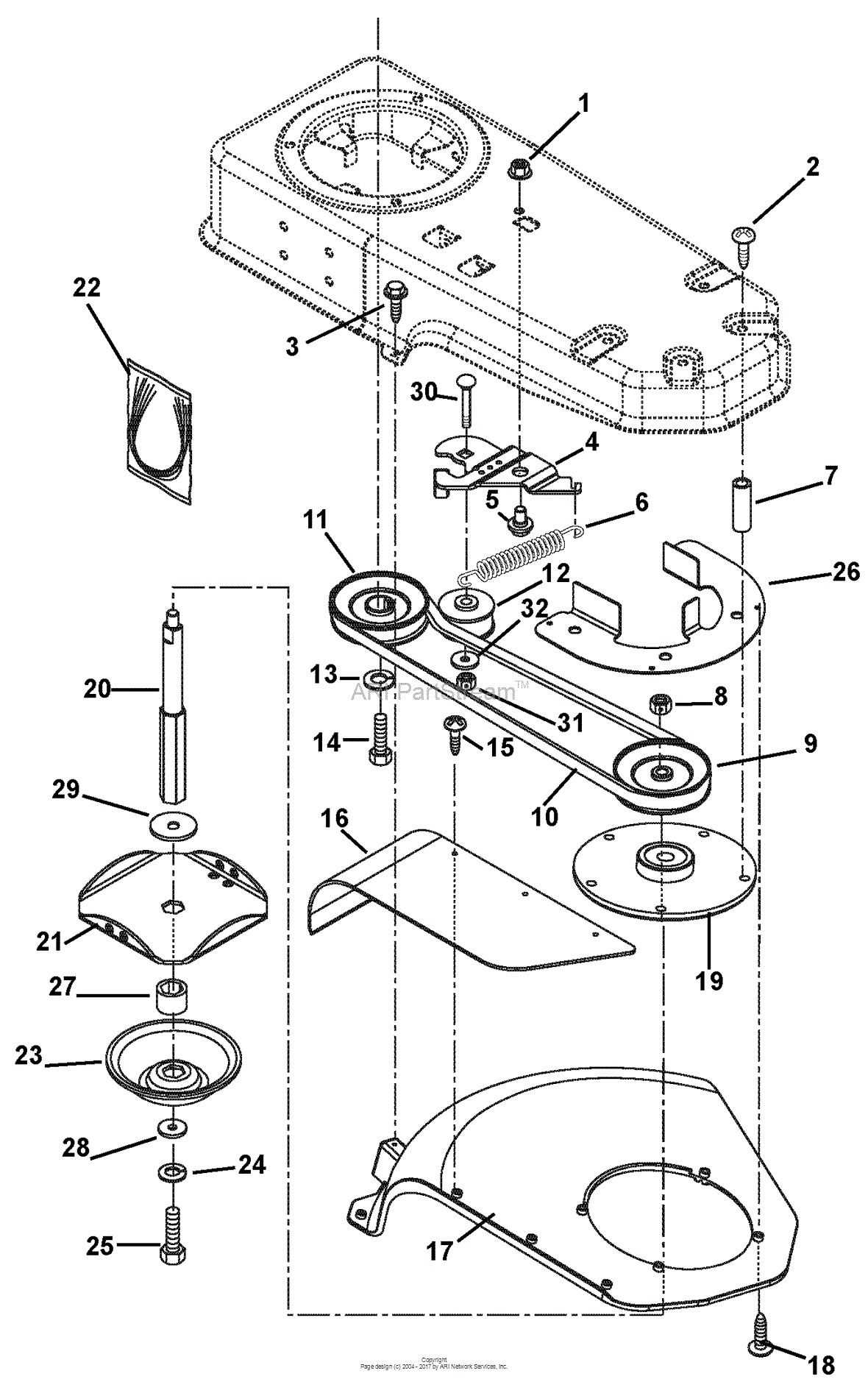

Each machine is made up of various elements, each with a distinct role. By understanding the layout and design, you can easily spot which part might be causing issues or needs attention. The components are usually labeled, but having a clear understanding of their functions makes diagnosis quicker and easier.

Commonly Found Elements

- Engine components: Vital for driving the machine and powering other parts.

- Auger system: Responsible for breaking down snow or debris into smaller pieces.

- Chute: Directs material away from the machine after it’s processed.

Identifying and Replacing Damaged Parts

Sometimes, a malfunction can be traced back to a specific part. If you know what each piece does, you can narrow down the source of the problem. It’s always a good idea to inspect the components regularly for wear and tear, and replace them as soon as issues are identified.

Steps to Take for a Smooth Repair

- Refer to the equipment manual to locate the exact part needing replacement.

- Disconnect power sources and remove any covering to access the faulty part.

- Carefully remove and replace the damaged component with a new one.

- Reassemble and test the device to ensure it’s working properly.

Maintaining Equipment Efficiency

Regular maintenance is essential to keep your device running at its best. Routine cleaning, lubrication, and part checks can prevent most problems from arising. Make it a habit to inspect your machinery after each use to spot potential issues early.

Understanding Key Machine Components and Their Maintenance

Properly maintaining outdoor equipment relies heavily on understanding how each individual element works together. By being familiar with the main components, users can easily identify problems, perform necessary repairs, and ensure the device operates at peak efficiency. This section will guide you through the main components, offer insights into common issues, and explain how to interpret visual guides for easy identification.

How to Interpret the Visual Guide

Every device has a specific arrangement of parts, and understanding this structure is essential for quick troubleshooting. The visual guide helps users pinpoint each key component and its function, making it easier to diagnose problems. It’s essential to follow the layout step-by-step, ensuring all elements are accounted for, from the engine to the mechanisms that process debris.

Common Issues and How to Fix Them

Over time, parts may wear out or become damaged due to regular use. Identifying issues such as a malfunctioning engine, clogged mechanisms, or broken connectors is easier when you understand the role of each component. In many cases, worn-out elements can be replaced or repaired to restore full functionality.

To replace a damaged piece, simply refer to the guide, locate the faulty element, and swap it out with a new one. Regular checks can help catch minor issues before they turn into more significant problems, saving both time and money.

Maintenance Tips for Longevity

Routine maintenance is the best way to extend the lifespan of your equipment. Keep all moving parts lubricated, clean out any debris after use, and check for signs of wear regularly. A well-maintained machine not only lasts longer but also works more efficiently, reducing the risk of costly repairs.