When it comes to maintaining and repairing your snow vehicle, having a clear understanding of its structure and key elements is essential. A comprehensive breakdown of each component can make troubleshooting and replacing parts more efficient, ensuring your vehicle operates at its best.

Being familiar with the layout of various sections allows you to easily identify potential issues and address them quickly. Whether you’re a beginner or an experienced rider, knowing where each crucial part is located and how it functions is a vital part of keeping your snowmobile in top condition.

Proper care and knowledge are key to extending the life of your machine. By understanding its inner workings, you can perform basic maintenance and repairs with confidence. In this article, we will explore the critical elements and how to maintain them properly.

Understanding Snowmobile Components

Each snow vehicle consists of several interconnected parts that work together to ensure smooth operation. From the engine to the suspension, every component plays a crucial role in the overall performance of the machine. Familiarizing yourself with these essential elements allows for better maintenance and faster troubleshooting when issues arise.

Key Elements of a Snow Vehicle

The primary components of any snow vehicle include the engine, transmission, steering system, and suspension. Each part has its own specific function that contributes to the vehicle’s overall performance. The engine provides the necessary power, while the suspension ensures a smooth ride over uneven terrain. Understanding the role of each element helps you recognize potential problems and address them quickly.

Why Component Knowledge Matters

Having an in-depth understanding of the structure and function of various components can save both time and money in repairs. When you’re familiar with the layout of the machine, you can easily spot worn-out or malfunctioning parts. This knowledge also makes it easier to perform routine maintenance and make informed decisions when purchasing replacement parts.

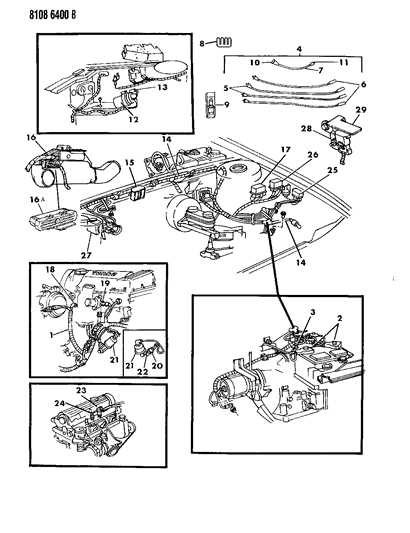

How to Read a Components Layout

Interpreting a visual guide for mechanical elements is crucial when performing repairs or replacements on your snow vehicle. These illustrations help you identify the exact location of each part, allowing you to pinpoint issues or make informed decisions during maintenance. Understanding the way these layouts are organized can simplify the entire repair process.

The layout typically includes a detailed drawing of each section of the vehicle, with labels identifying individual components. Each part is usually numbered or marked, which corresponds to a list of descriptions, making it easy to find specific elements. These visual guides are designed to be as clear as possible, ensuring that anyone, from beginners to experts, can follow the instructions without confusion.

To read these guides effectively, start by familiarizing yourself with the layout’s structure. Notice how the components are grouped and the flow of the system. Pay attention to the connections between parts, as this can provide valuable insights into how the machine functions as a whole. With practice, you’ll be able to quickly locate the parts you need and understand how they fit into the larger system.

Tips for Maintaining Your Snowmobile

Regular maintenance is essential for keeping your snow vehicle running smoothly and extending its lifespan. By performing routine checks and addressing minor issues before they become major problems, you can ensure optimal performance during every ride. Effective maintenance not only helps with the vehicle’s functionality but also promotes safety and reliability.

One of the most important aspects of upkeep is monitoring the engine’s condition. Regularly change the oil and check for any leaks or unusual noises. Keep the fuel system clean, and ensure the spark plugs are in good condition to maintain efficient engine operation. Additionally, inspect the cooling system to prevent overheating, especially during extended use in harsh conditions.

Another crucial area to focus on is the suspension. Ensure that the shocks and springs are functioning properly and are not worn out. Regularly check the track tension and alignment to avoid excessive wear. Finally, always clean and lubricate moving parts to reduce friction and prevent rust, especially after riding in wet or salty environments.