Understanding the inner workings of a chainsaw is essential for maintaining its performance and ensuring longevity. Having a clear view of the various parts and how they fit together can make repairs, adjustments, and troubleshooting much easier. This knowledge allows users to identify potential problems and replace faulty components efficiently.

By studying the layout and configuration of the machine, owners can become more confident in their ability to perform routine maintenance or repairs. A visual guide helps break down complex systems into manageable parts, providing clarity for both novice and experienced users.

In this section, we will focus on essential components that keep the chainsaw running smoothly. We will also highlight common issues and the necessary replacements, making it easier to keep your tool in top working condition. Regular maintenance is crucial, and understanding the key elements will help avoid unexpected failures during operation.

Understanding the Chainsaw Components

Every chainsaw consists of several critical elements that work in harmony to ensure smooth operation. These components play distinct roles, from powering the motor to controlling the cutting mechanism. Gaining an understanding of each part’s function allows for better troubleshooting, repair, and maintenance. Familiarity with these key elements will make handling the tool more efficient and reduce the likelihood of malfunctioning.

Engine and Power System

The engine is the heart of the machine, generating the necessary force to drive the chain. It typically includes various components such as the fuel system, spark plug, and ignition system, each playing a crucial role in ensuring smooth startup and consistent operation. Regular inspection of the engine can prevent common issues like poor performance or failure to start.

Cutting Mechanism and Chain Assembly

The cutting system is made up of the guide bar, chain, and sprocket, which are responsible for making precise cuts. The chain, driven by the engine, moves along the bar with the help of the sprocket, which engages with the teeth of the chain. Maintaining the sharpness of the chain and ensuring proper tension are key to achieving clean, efficient cuts. Routine checks for wear and tear on the chain and bar are essential to keep the machine performing at its best.

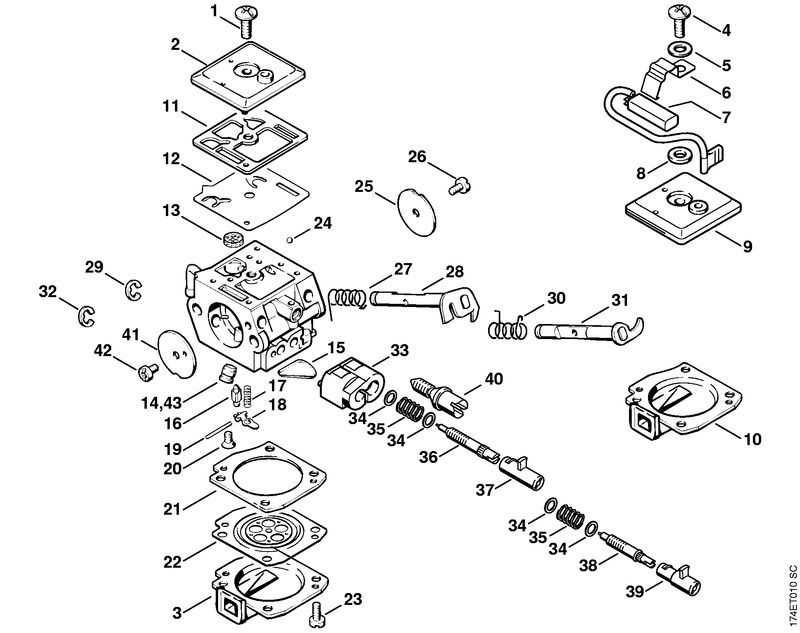

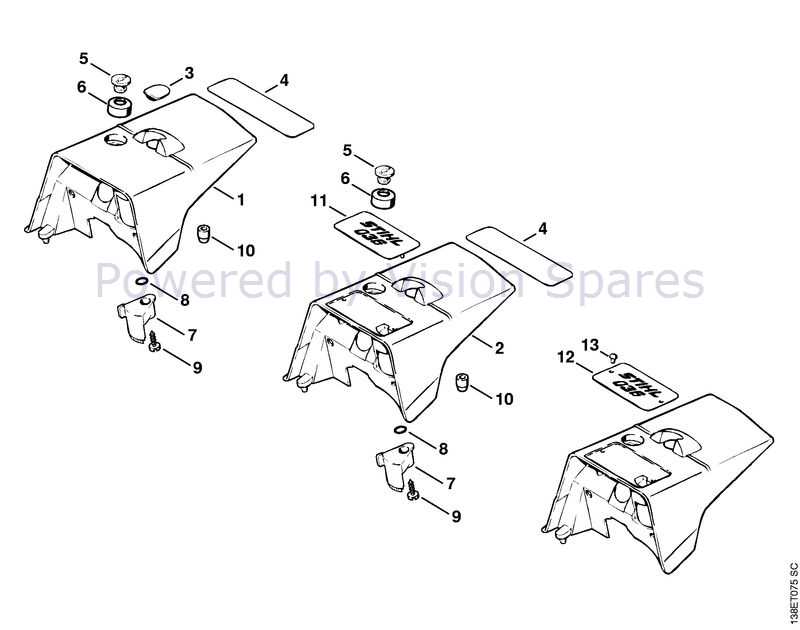

How to Read a Chainsaw Component Layout

Understanding a visual representation of your tool’s components can greatly improve your ability to identify, troubleshoot, and replace parts. These layouts are designed to break down the machine into its essential elements, allowing you to quickly locate specific parts and understand their function within the overall system. Properly interpreting these diagrams is crucial for accurate repairs and effective maintenance.

Identifying Key Components

Each component is usually marked with a number or label, which corresponds to a list of parts, helping you identify the exact piece you need. It’s important to pay attention to the shape and position of each element, as it provides clues about how the parts are assembled and connected. Knowing how to spot these markings will save you time when sourcing replacements or performing repairs.

Understanding Connections and Assembly

Another vital aspect is recognizing how the various parts interact with one another. Lines and arrows often indicate the direction of motion or how pieces connect within the system. By following these connections, you can visualize how the tool functions as a whole and better understand potential areas that may require attention. Clear identification of these relationships ensures efficient repair work and accurate reassembly after any maintenance tasks.

Common Issues and Spare Components for Chainsaws

Even with regular maintenance, tools can experience wear and tear over time. Understanding the common issues that arise with chainsaws is crucial for efficient repairs. Many of these problems are related to specific components that often need replacing or adjustment. Knowing which parts are most likely to fail allows users to quickly address issues and restore functionality.

Frequent Malfunctions

One of the most common issues is difficulty starting the engine. This could be due to a worn spark plug or issues with the fuel system, such as a clogged fuel filter. Another frequent problem is improper chain movement, often caused by a damaged sprocket or chain that has lost its tension. Regular inspection of these areas can help identify problems before they become more serious and expensive to fix.

Necessary Replacements

When it comes to replacements, some components are more likely to need attention than others. The chain, guide bar, and air filter are parts that should be inspected regularly. Additionally, the fuel system, including the fuel lines and carburetor, can deteriorate over time and may need to be cleaned or replaced. Having spare components on hand ensures that you can quickly address any issues without having to wait for parts to be delivered.