When it comes to maintaining your cleaning appliance, understanding the individual components is key. Knowing how each part works together ensures optimal performance and longevity of the machine. This guide will provide clarity on the essential elements that make up the device, helping you to troubleshoot and maintain it effectively.

Properly identifying and handling the various pieces of your cleaning tool can significantly improve its functionality. Regular inspection, care, and timely replacement of worn-out components can prevent costly repairs and extend the appliance’s lifespan. By familiarizing yourself with these details, you can keep your device running smoothly for years to come.

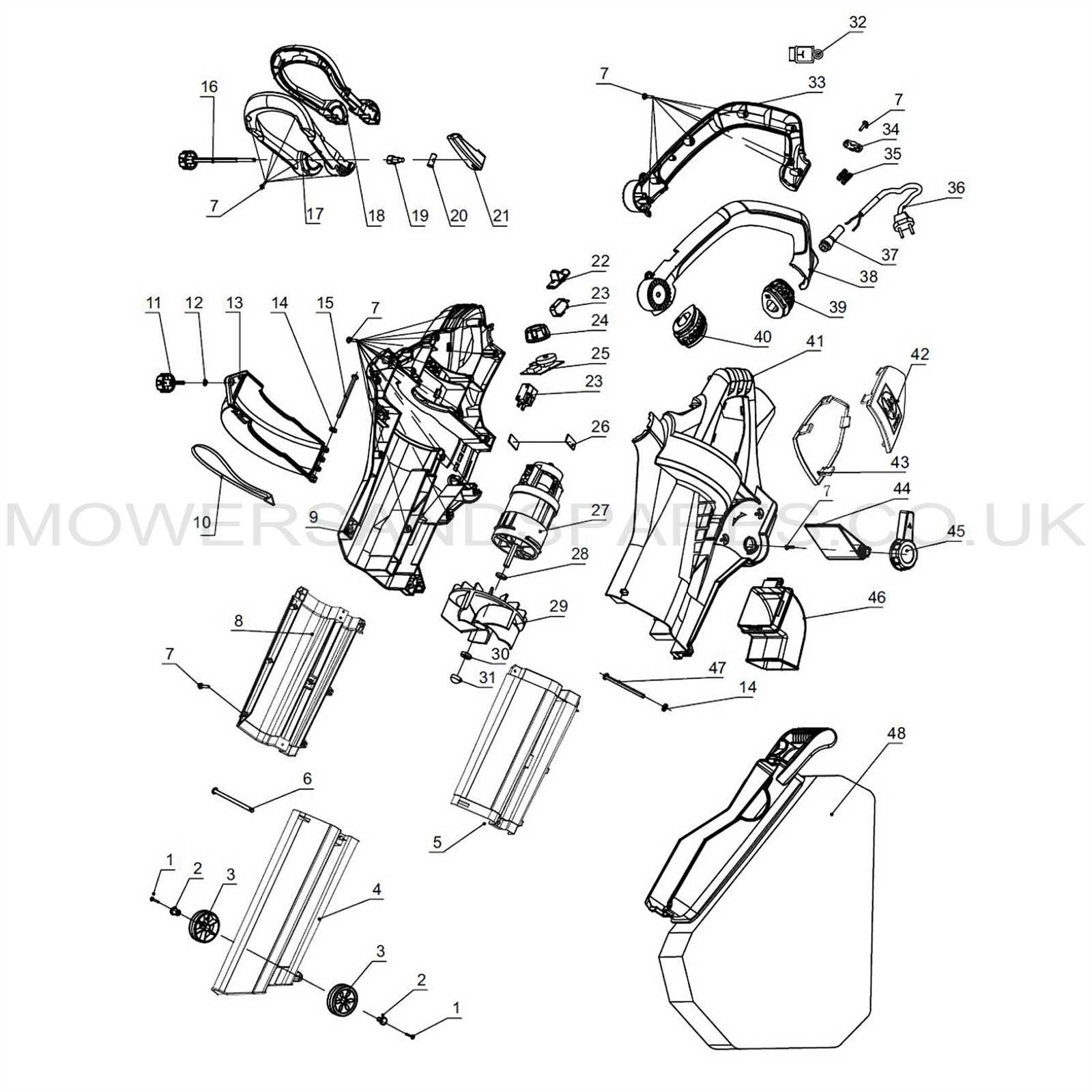

Bissell CrossWave Components Overview

Every modern cleaning device consists of various key elements that work in harmony to ensure effective cleaning. Understanding the structure of these components is essential for maintaining your appliance’s efficiency and performance. Each individual section plays a crucial role in how the machine operates, from suction power to fluid distribution.

The main components include motorized brushes, water tanks, filtration systems, and power controls. These parts are interconnected, enabling the tool to handle both wet and dry messes with ease. Regular checks and maintenance on these crucial elements help prevent breakdowns and ensure consistent results with every use.

Familiarity with each element will also guide you when it comes time to replace or clean specific parts. This proactive approach allows for smoother operation and more effective upkeep. By learning how each part functions, users can troubleshoot minor issues and ensure their device continues to serve its purpose over the long term.

How to Identify Key Parts

Recognizing the crucial components of your cleaning device is an important step in ensuring its optimal functioning. Each part is designed to perform a specific task, whether it’s for cleaning, water management, or power regulation. Knowing what each section does and how to spot them is essential for effective troubleshooting and maintenance.

Begin by identifying the motorized cleaning brushes, which are responsible for agitating dirt and debris. These can usually be found at the base of the unit, designed for easy removal and replacement. Next, focus on the water tanks, which may include separate compartments for clean and dirty water. Ensuring these are properly aligned and cleaned after use is vital for maintaining the system’s efficiency.

Don’t forget the filtration system, which plays a key role in capturing dust and debris. This component can often be located near the suction area, and it may require regular cleaning to maintain optimal airflow. Lastly, examine the power controls and cables to ensure they are intact and functioning, as they regulate the operation of the entire device.

Replacing and Maintaining CrossWave Parts

Regular maintenance and timely replacement of key components are essential for the longevity and performance of your cleaning tool. Over time, certain parts may wear out or become less efficient, which can affect the overall cleaning quality. Staying proactive in replacing these elements ensures your device continues to perform at its best.

Start with the brushes, as they are often the most used parts in the machine. These can become clogged or damaged, reducing their effectiveness. Replacing them periodically ensures that the cleaning surface is adequately agitated, improving results. Likewise, inspect the water tanks and make sure they are clean and free from debris, which can cause blockages in the system.

Maintaining the filtration system is equally important. A clogged filter can hinder suction power and decrease cleaning efficiency. Regularly cleaning or replacing the filter helps maintain consistent performance. Lastly, check the power cords and switches, ensuring they are intact and functioning properly to avoid any interruptions in operation.