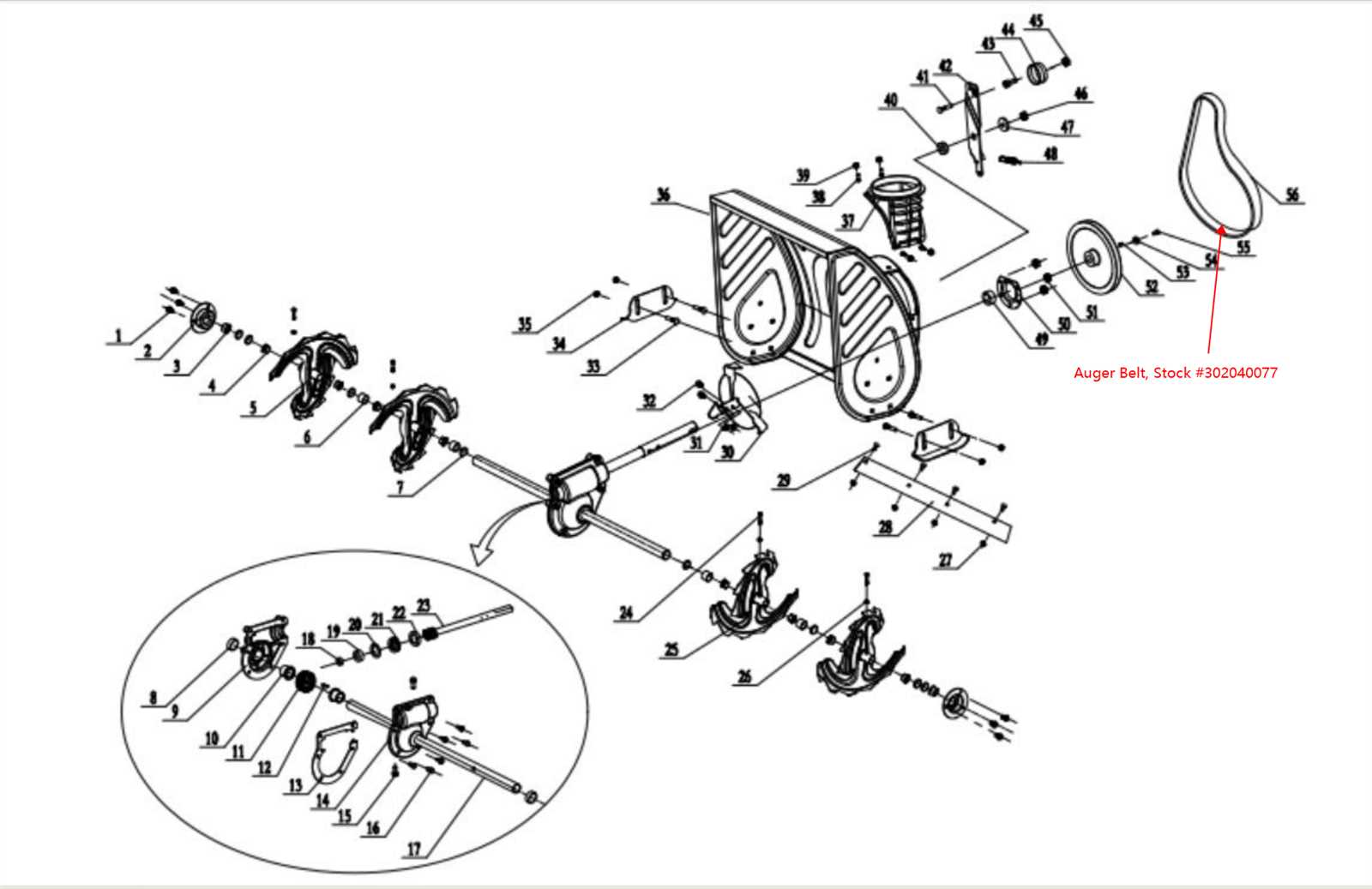

Understanding the individual elements of a machine is crucial for ensuring its proper functioning and longevity. Knowing how each piece contributes to the overall performance allows for effective troubleshooting and repairs. Whether it’s replacing a faulty part or performing routine checks, recognizing the key components plays a vital role in maintaining efficiency.

In this guide, we will explore a detailed breakdown of essential parts that make up the core of your equipment. From identifying each unit to understanding its role, you will gain insights into the proper handling and care necessary for smooth operation. By following these steps, you can easily manage maintenance and repairs, keeping your machine in top condition for longer use.

Understanding these parts and their functions empowers you to address any issues promptly. Armed with this knowledge, you can confidently tackle repairs and avoid unnecessary delays, ensuring your equipment operates at its best.

Understanding Mower Components

To ensure smooth and efficient operation, it is important to familiarize yourself with the different elements that make up your machine. Each component serves a specific function and contributes to the overall performance. Recognizing these parts will help in diagnosing issues, performing necessary repairs, and carrying out routine maintenance.

Key Elements of the Equipment

Various parts such as the engine, blades, and wheels work together to provide the necessary power and functionality. The engine is responsible for generating power, while the blades perform the cutting task, and the wheels facilitate movement. Understanding how these components interact helps in identifying the root causes of potential issues.

Maintenance and Troubleshooting

Regular inspections of the individual units can prevent many common problems. For example, keeping the engine clean and ensuring it runs smoothly can reduce the likelihood of breakdowns. Similarly, checking the blades for damage or wear allows for proper cutting performance. Routine care and prompt attention to worn-out components are key to extending the life of your machine.

How to Identify Key Equipment Components

Properly identifying the essential elements of your machine is crucial for effective maintenance and repairs. Recognizing the role and function of each unit helps in diagnosing issues quickly and accurately. By knowing what each piece does, you can make informed decisions when troubleshooting or replacing components.

Start by familiarizing yourself with the main functional components. The engine is the powerhouse, responsible for generating the energy needed for operation. The blades are responsible for cutting, and they should be checked regularly for damage or dullness. The chassis holds everything together, and the wheels enable movement across various terrains.

Once you understand these key components, you can easily locate them within the machine, ensuring you know where to look when performing inspections or repairs. Regular identification and inspection will keep your equipment running smoothly and prevent unexpected issues.

Step-by-Step Equipment Breakdown

Understanding the inner workings of your machine is essential for effective troubleshooting and repairs. A clear, step-by-step breakdown of its structure allows you to easily identify each component and how they fit together to ensure proper function. This guide will walk you through the process of recognizing each part and its specific role within the overall system.

Start by examining the core units of the machine. First, identify the power source that drives the entire system. Once that is clear, move on to the cutting mechanism, which is typically the most critical part in ensuring functionality. Afterward, check the mobility system–the wheels and any other parts that allow movement and adjustment of the machine.

By breaking down the equipment in this manner, you’ll gain a comprehensive understanding of its structure. This approach makes it easier to identify potential issues, replace worn-out components, and perform regular maintenance to keep everything working smoothly.

Essential Parts for Maintenance and Repair

Proper upkeep and timely repairs are crucial for the longevity of any equipment. Identifying the right components for regular maintenance ensures that your machine operates at its best. Knowing which units require the most attention helps in preventing unnecessary breakdowns and extending its lifespan.

Key Components to Monitor

Focus on the engine, as it is the source of power. Regular checks on its performance, including cleaning and oil changes, prevent malfunctions. The blades are another critical part that needs periodic inspection to maintain cutting efficiency. Worn or damaged blades should be replaced promptly for optimal operation.

Parts Needing Regular Attention

Other essential components include the wheels, which ensure smooth movement, and the belts that transfer power from the engine to other parts. These should be examined for wear and adjusted or replaced as necessary. By focusing on these key areas, you can ensure reliable performance and minimize the risk of future problems.

Common Equipment Issues and Solutions

Like any machine, regular use can lead to various issues that affect performance. Recognizing the most common problems early on allows for quick fixes, preventing further damage and ensuring the continued functionality of your equipment. Below are some typical problems and their respective solutions.

- Engine Won’t Start: This could be caused by a variety of factors such as a dead battery, fuel issues, or a faulty ignition system. Check the fuel level and ensure the battery is charged.

- Unusual Noises: Uncommon sounds often indicate loose parts or worn-out components, particularly in the blades or belt areas. Tightening bolts or replacing the affected units can resolve this issue.

- Uneven Cutting: If your machine is leaving uncut patches, the blades may be dull or damaged. Sharpen or replace the blades for a smoother, more efficient cut.

By staying alert to these common issues and addressing them promptly, you can avoid costly repairs and maintain optimal performance. Regular maintenance and checks are key to keeping your equipment in top shape.