Proper care and understanding of machine components are crucial for ensuring longevity and optimal performance. Knowing how each part fits into the system can save both time and effort during repairs. It is vital to be familiar with every element, its role, and how it interacts with others to maintain smooth functionality.

In this section, we will explore the critical components involved in the operation of outdoor power equipment. Understanding their structure and how to identify them will empower you to handle maintenance tasks with confidence. By familiarizing yourself with the assembly, you can ensure a more efficient and effective repair process.

Knowing these elements not only enhances repair accuracy but also helps prevent common issues that may arise from improper handling. Familiarity with the assembly leads to smoother maintenance sessions and can ultimately save money on costly repairs.

Understanding Key Components for Maintenance

To effectively maintain and repair any outdoor machinery, it’s essential to grasp the basic structure and function of each individual component. Each part plays a crucial role in the smooth operation of the system, and understanding their relationships helps ensure that the equipment runs optimally. By familiarizing yourself with these components, you can more easily troubleshoot issues and perform maintenance tasks.

Core Elements of the Assembly

The assembly consists of various elements that are responsible for power delivery, control, and safety. These components interact in a carefully engineered way, making it important to recognize how each contributes to the machine’s functionality. Understanding the layout of these parts helps in diagnosing common problems and ensures proper handling during maintenance.

Impact of Proper Handling

Handling each part correctly can significantly extend the life of the equipment. Whether it’s regular cleaning or replacing a worn-out component, knowing what to focus on can prevent damage to other parts. With proper care, you can maintain peak performance and reduce the likelihood of unexpected breakdowns.

Essential Components for Effective Maintenance

Effective upkeep of outdoor machinery relies on understanding and maintaining key elements that ensure proper functionality. Regular attention to specific components not only improves the lifespan of the equipment but also enhances its performance. Focusing on essential parts helps avoid larger issues down the line and ensures smooth operation during use.

Key Mechanisms to Prioritize

Among the various mechanisms, those that manage power flow, air intake, and fuel efficiency should be closely monitored. These are often the most susceptible to wear and tear, so they require regular checks. Keeping these parts in optimal condition can prevent system failures and keep everything running efficiently.

Maintenance Strategies for Longevity

Adopting regular maintenance routines focused on cleaning, lubrication, and timely replacement of worn parts will minimize costly repairs. By maintaining the most critical parts, you’ll ensure that the equipment remains in top shape and performs effectively over time.

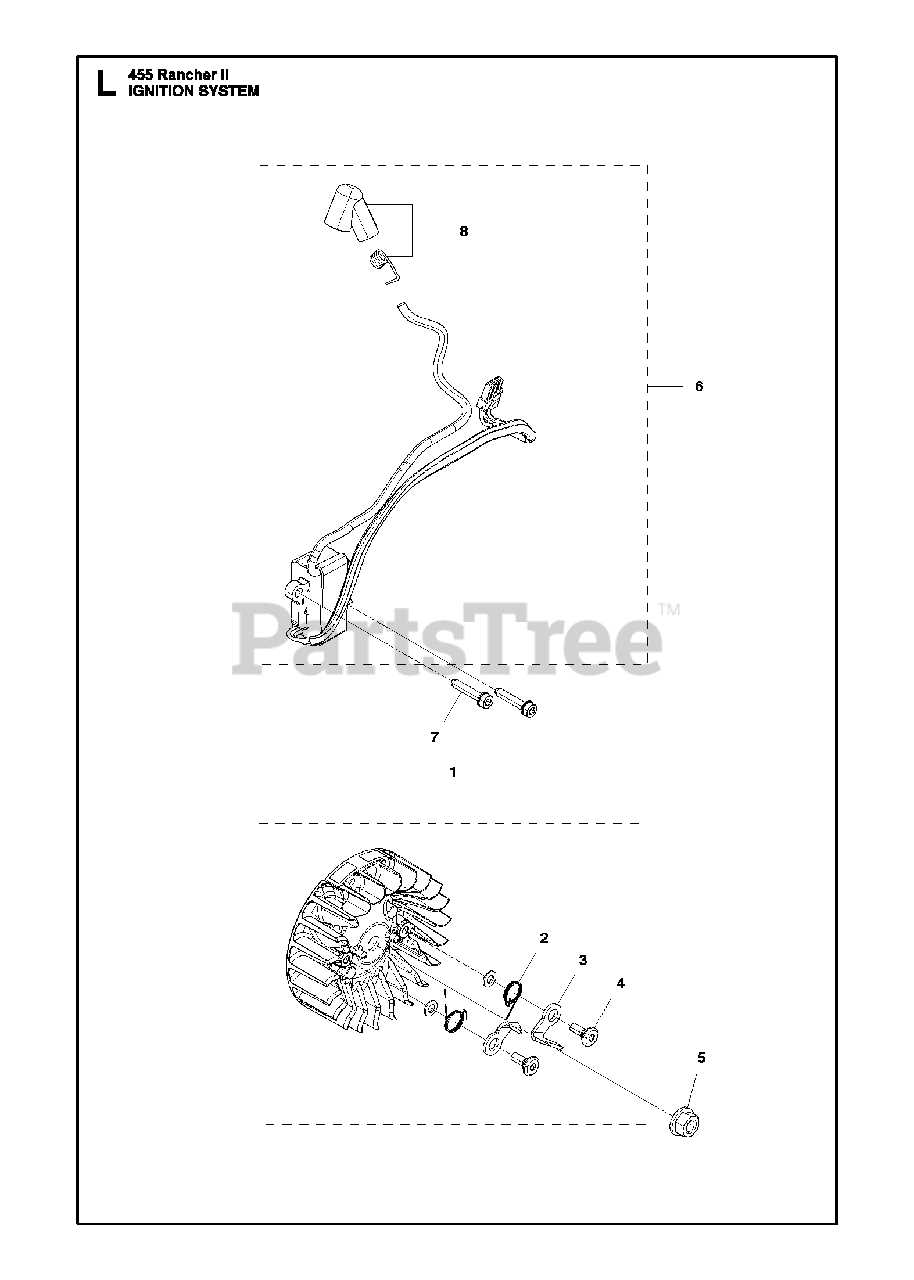

How to Interpret the Assembly Overview

Understanding the visual representation of machinery components is essential for proper assembly and repair. These illustrations provide a clear and organized way to see how each element fits within the system, allowing for easy identification of parts and their respective placements. Knowing how to read these visuals helps simplify maintenance tasks and enhances the overall efficiency of repair work.

When interpreting these visual guides, pay close attention to labels and identifiers that correspond to each component. These indicators make it easier to match physical elements with their respective locations. The layout of the diagram is designed to offer a comprehensive understanding of how everything connects, ensuring that each part is accounted for during maintenance or assembly.