Maintaining and repairing your home’s mechanical systems can seem overwhelming, but with the right knowledge, you can easily navigate through the process. Every mechanism consists of several essential elements that work together to ensure smooth functionality. Familiarizing yourself with these key components is the first step toward efficient repairs and proper maintenance.

Knowing the layout and function of each individual part is crucial for troubleshooting any issues that arise. Whether you’re replacing a faulty element or performing routine maintenance, having a clear understanding of how the system is assembled helps you identify what needs attention and when.

By carefully examining each component, you can ensure everything is working properly and efficiently. This article will guide you through the various parts of your system, helping you become more confident in diagnosing and resolving problems as they occur.

Understanding Craftsman Garage Door Openers

The smooth operation of automated home systems depends on a variety of interconnected elements. These systems allow for convenient access to secure areas, providing both functionality and safety. A well-designed mechanism relies on a set of components that work in harmony to deliver reliable performance. To ensure longevity and efficiency, it’s essential to understand how each part contributes to the overall function of the system.

Basic Components and Functions

At the heart of any automated entry system is the motor, which powers the movement of the mechanism. Alongside this, support elements like tracks, rollers, and cables assist in the smooth operation, guiding the motion and ensuring proper alignment. Each piece plays a role in reducing wear and tear, preventing jamming, and facilitating smooth operation over time.

How to Maintain Your System Effectively

Regular inspection and maintenance are key to preventing malfunctions. Ensuring that all components are correctly aligned and lubricated helps avoid unnecessary strain on the motor and mechanical parts. A proactive approach to repairs–such as replacing worn components and addressing any issues before they escalate–can save time and money in the long run. Understanding how each part contributes to the system’s overall function makes it easier to diagnose issues quickly and maintain optimal performance.

Key Components of Craftsman Opener Systems

Every automated access system consists of several essential elements that ensure reliable functionality. These key components each have a specific role in maintaining smooth and efficient operation. Understanding their individual functions and how they interact with one another is critical for both troubleshooting and regular maintenance.

| Component | Function |

|---|---|

| Motor | Drives the movement of the entire system, providing power to the mechanism. |

| Tracks | Guide the movement of the mechanism along a fixed path, ensuring smooth motion. |

| Rollers | Facilitate easy movement along the tracks by reducing friction and wear. |

| Springs | Provide tension to balance the weight of the system, aiding in smooth and controlled motion. |

| Cables | Assist in the lifting and lowering motion by connecting the system’s motor to the moving parts. |

These fundamental components work together to provide seamless operation. Regular maintenance and inspection of each part are essential to ensure the system runs optimally and any issues are caught before they cause significant problems.

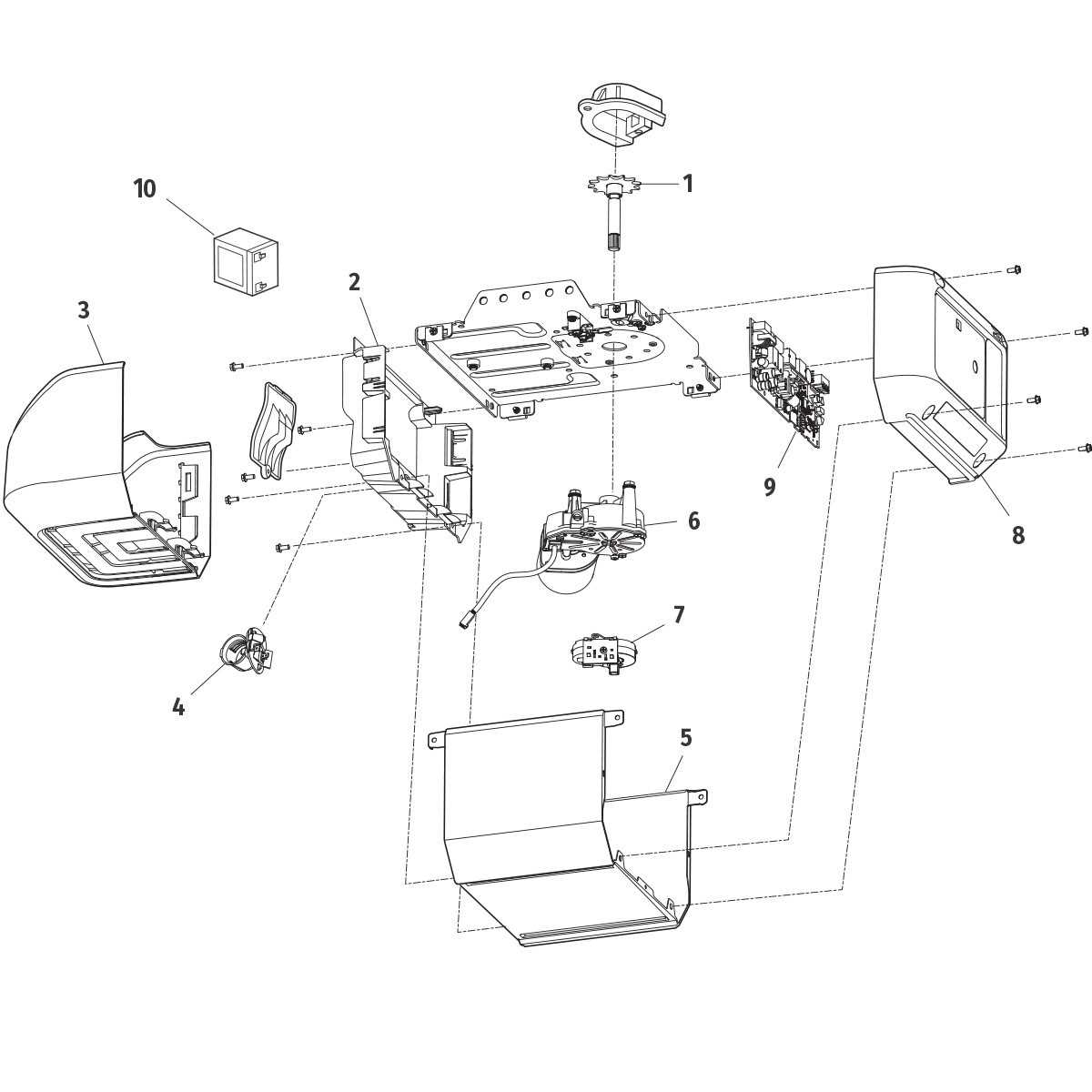

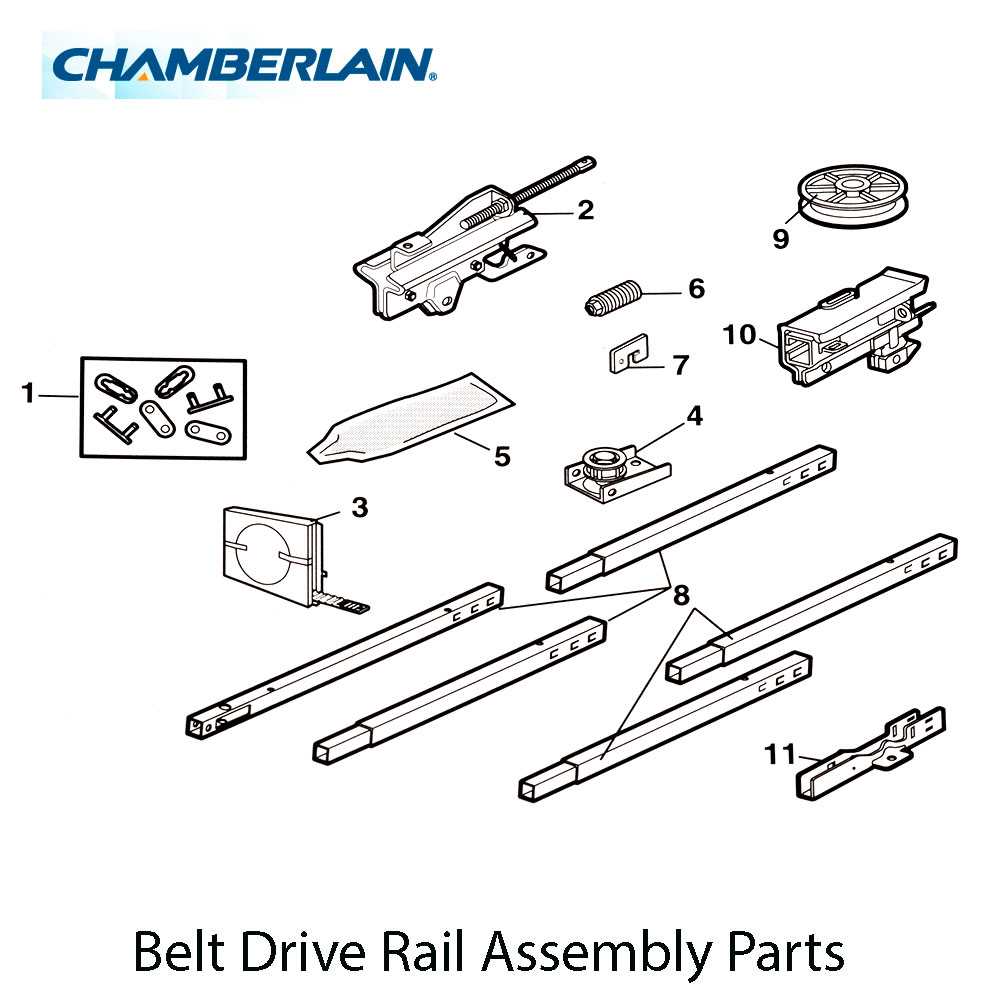

How to Identify Parts in the Diagram

Understanding the layout of a system’s components is essential for both maintenance and repair. A clear visual representation can make it much easier to recognize each element and its role in the overall functionality. Identifying the individual components in these diagrams allows you to quickly locate specific parts when troubleshooting or replacing them.

When reviewing the diagram, start by looking for labels that clearly mark each part. These labels often correspond to part numbers or names, which can help you cross-reference with your manual or replacement guide. Pay close attention to the arrangement of the components, as it will give you an idea of how each one interacts with the others.

In addition, focus on the different shapes and lines used to represent each element. Some diagrams use color coding or patterns to distinguish between mechanical, electrical, and structural parts, making it easier to identify which section requires attention. Once familiar with the key components and their locations, you’ll be able to diagnose issues and perform repairs more efficiently.

Common Issues and Solutions with Parts

Over time, mechanical systems can develop issues that affect their performance. Recognizing common problems and understanding how to address them is key to maintaining proper functionality. Below are some frequent issues that may arise, along with practical solutions to keep everything running smoothly.

- Unresponsive System: If the mechanism is not responding when activated, the issue could be with the motor or the power supply. Check the connections and ensure the motor is receiving power.

- Sluggish Movement: If the movement is slow or jerky, it’s likely due to worn-out rollers or insufficient lubrication. Replace the rollers and apply lubricant to reduce friction.

- Misalignment: Misaligned tracks can cause operational problems. Inspect the tracks for bends or obstructions, and adjust them as necessary to restore alignment.

- Strange Noises: Unusual sounds often indicate issues with the springs or cables. These components should be inspected for wear, and damaged parts should be replaced to prevent further damage.

- Overheating Motor: If the motor is overheating, it could be due to an overworked system or insufficient cooling. Ensure the motor is properly ventilated and not overburdened with too much weight or friction.

By addressing these common problems early on, you can extend the lifespan of the system and ensure it continues to function reliably. Regular maintenance and early intervention are essential for avoiding major repairs in the future.

Maintaining Your System

Proper upkeep is essential for ensuring the longevity and efficient performance of your automated system. Regular maintenance helps identify potential issues early, reducing the risk of major repairs. By performing simple checks and taking preventive measures, you can keep your system running smoothly and avoid unexpected disruptions.

Start by inspecting the key components for wear and tear. Look for signs of rust, corrosion, or misalignment that could hinder operation. Clean and lubricate moving parts, such as rollers and tracks, to reduce friction and extend their lifespan. Tighten any loose bolts or screws to ensure all parts are securely in place.

It’s also important to regularly check the tension of the supporting elements, such as springs and cables. Over time, these can lose their effectiveness, causing strain on the motor and other parts. Replace them when necessary to maintain optimal performance. Finally, test the system periodically to ensure everything is functioning as expected and address any issues promptly before they escalate.