Maintaining your outdoor equipment requires a clear understanding of its essential elements. Knowing how each part functions and interacts is crucial for effective troubleshooting and repair. This knowledge not only helps ensure smooth operation but also extends the life of the machinery.

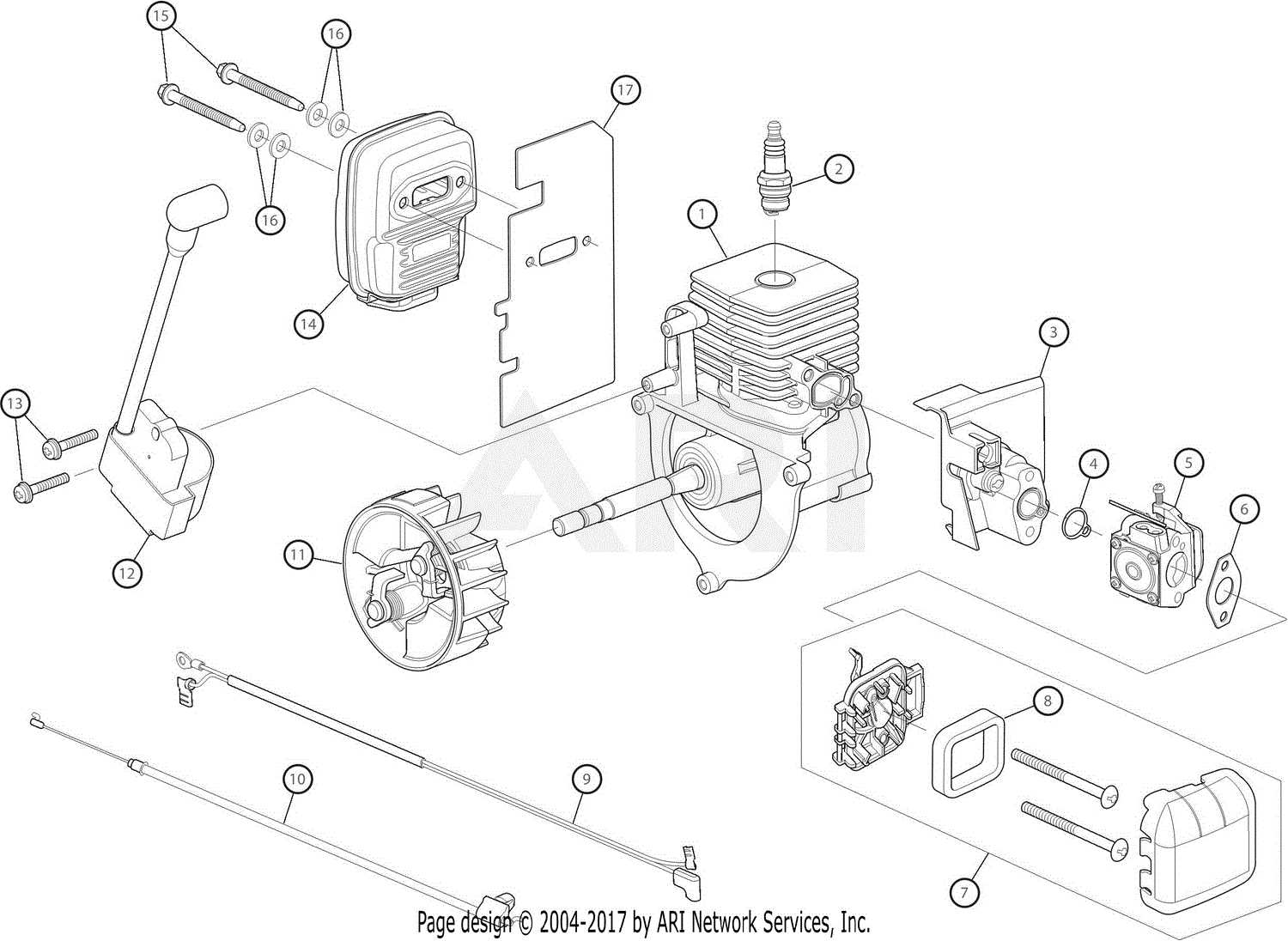

Identifying individual components is the first step in making repairs or adjustments. With a detailed visual guide, it becomes easier to pinpoint the exact piece needing attention. Whether it’s for replacing a worn-out element or upgrading a section, the process becomes straightforward.

Knowing how to navigate these guides and being familiar with the key components empowers you to take action promptly, avoiding delays in wintertime tasks. This approach allows for greater efficiency and better handling of equipment issues when they arise.

Understanding Key Components of Winter Machinery

Efficient operation of winter equipment depends on a solid understanding of its essential parts. Each piece plays a crucial role in ensuring that the system runs smoothly, from the power source to the moving components. Familiarizing yourself with these elements helps in troubleshooting and maintaining functionality over time.

Recognizing how the main sections work together allows for easier identification of issues. Whether it’s related to the engine, drive system, or clearing mechanism, understanding their specific tasks makes it simpler to detect when something is malfunctioning.

By becoming acquainted with the layout and role of each element, you’ll be better equipped to perform necessary repairs. This knowledge enhances your ability to keep the equipment in optimal condition, even through heavy usage during the colder months.

How to Read Machinery Component Illustrations

Understanding how to interpret visual guides for your equipment can significantly improve your maintenance experience. These illustrations are designed to provide clear identification of each element, making it easier to find the part you need for repairs or replacements. Properly reading these charts saves both time and effort when handling your equipment.

Identifying Key Sections

Start by identifying the major groups within the diagram. Often, the most important components are shown in distinct sections or grouped together for easy recognition. Look for labels or codes that correspond to each part, ensuring you can match them with the actual components of your equipment.

Understanding Part Numbers and Labels

Each component is usually assigned a unique identifier, often a number or letter code. These identifiers make it possible to locate specific items when ordering replacements or performing maintenance. Pay close attention to these labels, as they help in quickly pinpointing the exact part in need of attention.

Common Components for Equipment Maintenance

When maintaining your outdoor machinery, certain elements are more frequently involved in the upkeep process. These components endure significant wear and tear due to their constant use, making regular checks and replacements essential for optimal performance. Understanding which parts need the most attention can help keep your equipment running smoothly throughout the season.

Here are some of the most common components that require maintenance:

- Drive Belts: These are crucial for transmitting power to the working parts. Over time, they can wear out or snap, necessitating replacement.

- Clearing Mechanism: The blades or auger systems used for clearing snow or debris often need regular inspection for damage or build-up.

- Engine Filters: These components ensure proper airflow to the engine. Dirty or clogged filters can reduce performance and cause overheating.

- Fuel System: Components like fuel lines, valves, and tanks should be checked for leaks, cracks, or blockages that could affect fuel flow.

- Chassis and Frame: Keeping the main structure intact and free from rust is essential to prevent future breakdowns.

Routine inspection of these components will help identify potential issues early, preventing costly repairs or failures later on.