When it comes to maintaining your outdoor machinery, knowing its components is key to ensuring smooth operation and longevity. Whether you’re looking to replace a worn-out piece or troubleshoot an issue, understanding the layout of your equipment’s system can make all the difference.

In this section, we will explore how identifying individual elements of your device can help you recognize potential issues and find the right solutions. Proper knowledge of its structure allows for efficient repairs and helps prevent future complications.

Familiarity with each component ensures that you’re prepared to tackle basic maintenance tasks or more advanced fixes. The more you understand about the internal workings, the easier it becomes to make informed decisions about care and upgrades.

Understanding Craftsman M220 Parts Layout

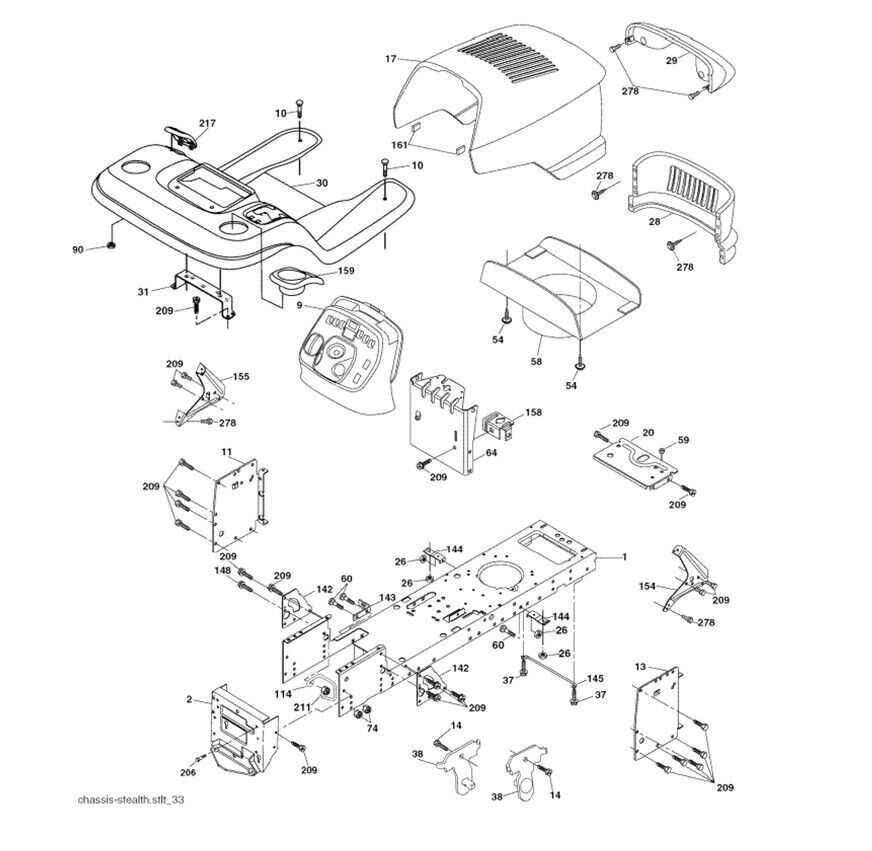

Understanding the configuration of the components in your outdoor equipment is essential for efficient maintenance and repair. By familiarizing yourself with the layout, you can easily identify the most critical elements and troubleshoot effectively when issues arise. A well-organized system ensures the smooth functioning of all moving parts, making it easier to pinpoint problems and carry out repairs when necessary.

Key Elements of the System

Every machine has its key components, each serving a specific function that contributes to overall performance. From the engine to the cutting mechanism, understanding how these elements work together ensures proper upkeep. Regular checks of these parts will help you identify wear and tear before they lead to more significant issues.

Maintaining a Proper Setup

Proper assembly and maintenance are crucial in keeping the equipment functioning optimally. Ensuring all parts are in the correct position and well-maintained prevents unnecessary breakdowns. Regular maintenance can also help avoid costly repairs and increase the lifespan of your tool.

Common Issues and Replacement Parts

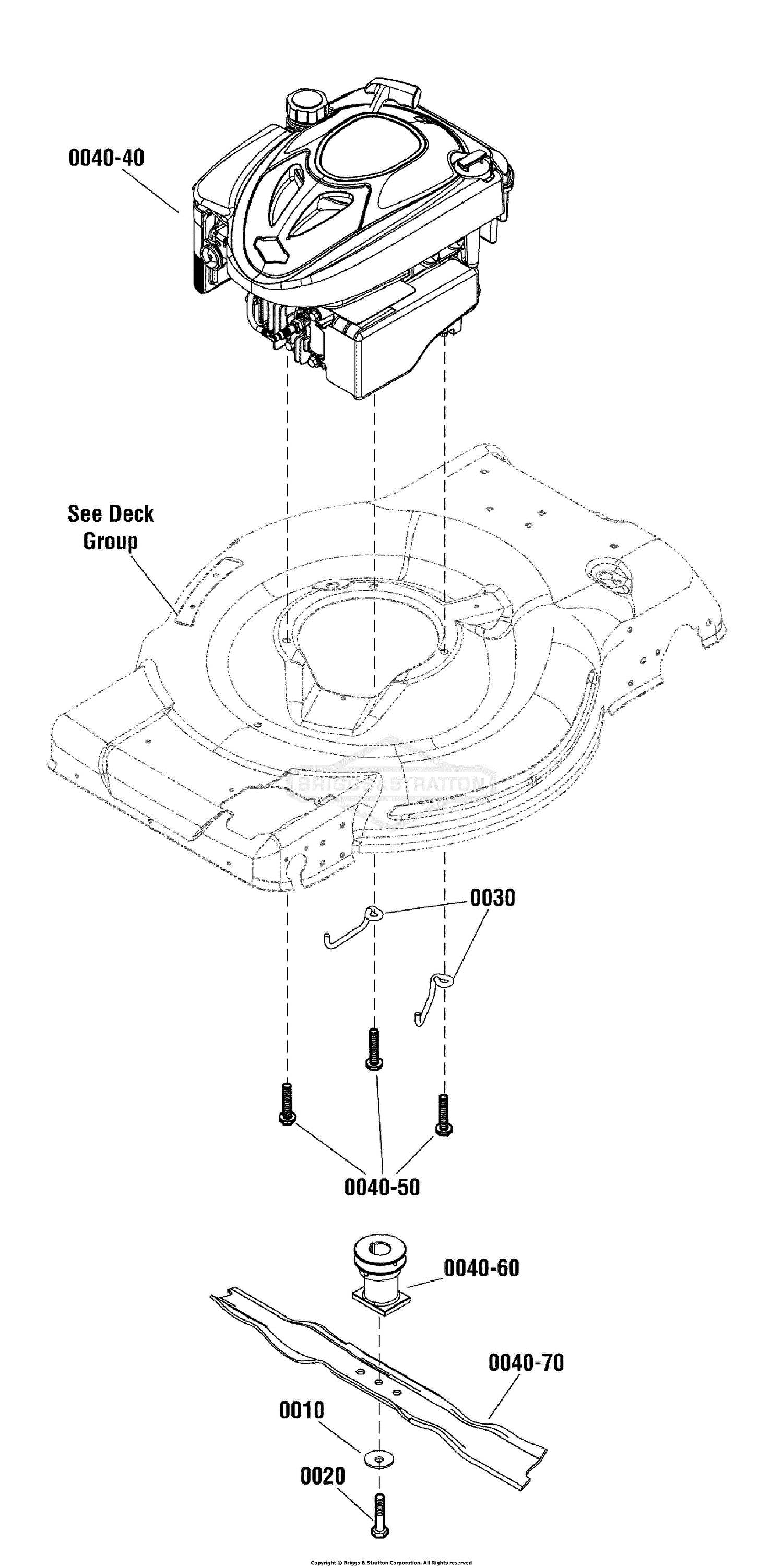

Every outdoor tool experiences wear and tear over time, which can result in common issues affecting performance. Recognizing these problems early allows you to replace the damaged components before they lead to more serious malfunctions. Identifying the specific part that needs replacement is a key factor in maintaining the tool’s efficiency and extending its lifespan.

Common Problems and Their Causes

One frequent issue is difficulty starting the machine. This can often be traced to a faulty ignition system or a clogged fuel filter. Another common concern is irregular or uneven cutting, which may indicate a dull or damaged blade. Ensuring these components are in top condition is crucial for optimal performance.

Replacing Worn-Out Components

Once you’ve identified the damaged components, replacing them with the appropriate substitutes is essential. High-quality replacements can restore the functionality of your tool, helping it to operate like new. Whether it’s a blade, belt, or filter, choosing the correct replacement ensures that the tool continues to perform efficiently, reducing the risk of further damage.

Step-by-Step Guide to Assembly

Assembling your outdoor equipment correctly is essential for ensuring safe and efficient operation. A clear understanding of the assembly process can save time and prevent common mistakes. By following a systematic approach, you can ensure that each component is properly connected and functions as intended, helping you avoid potential issues down the line.

Preparing the Tools and Components

Before starting the assembly, gather all necessary tools and components. This includes the engine, frame, cutting mechanism, and any additional accessories that need to be installed. Ensure all parts are in good condition and free of any debris that could interfere with assembly.

Assembling the Key Elements

Begin by attaching the main structural components, such as the frame and engine, ensuring all connections are secure. Next, install the cutting system or other mechanisms, following the manufacturer’s guidelines. Double-check each step as you proceed to ensure everything is aligned correctly, and tighten all bolts and screws to prevent future loosening.