Exploring the inner workings of a compact cooling system provides valuable insights into its efficiency and performance. Knowing the different elements involved and how they interact helps in maintaining the device and diagnosing potential issues. Proper comprehension of these key elements is crucial for anyone looking to optimize their system’s lifespan and functionality.

In this section, we will examine the crucial components that contribute to the smooth operation of small refrigeration units. From electrical connections to thermal management, each part plays a significant role in ensuring the unit operates efficiently. A detailed look at these elements not only aids in troubleshooting but also provides clarity on their individual functions.

Understanding the structure of these systems is essential, whether for repairs, upgrades, or simple maintenance. As you familiarize yourself with these features, it becomes easier to identify problems early, saving both time and resources. With this knowledge, you’ll be better prepared to handle challenges that may arise throughout the system’s life cycle.

Key Components of a Compact Cooling System

The functionality of a small cooling unit relies heavily on the cooperation of its essential components. Each element has a unique role in maintaining temperature control and ensuring energy efficiency. Understanding these components is critical for both troubleshooting and proper maintenance. These parts work in harmony to achieve the desired cooling effect and prevent system failure.

Refrigeration Cycle Elements

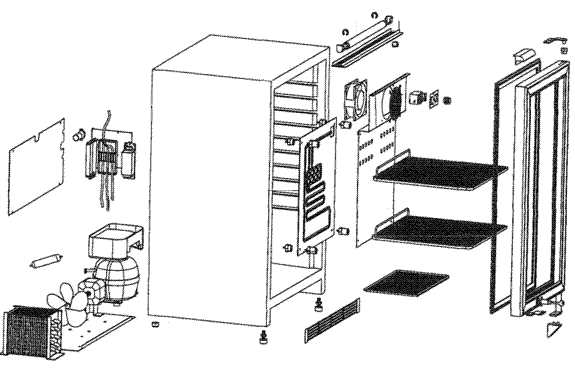

At the core of the system’s operation are the elements that drive the refrigeration cycle. This includes the compressor, condenser, expansion valve, and evaporator. The compressor circulates refrigerant through the system, while the condenser dissipates heat, and the expansion valve regulates pressure. Together, these parts enable the unit to maintain a stable internal environment.

Electrical and Control Systems

The electrical systems within a compact cooler are responsible for powering the mechanical components and ensuring proper functionality. This includes the thermostat, which controls the internal temperature, and the circuit board that manages the system’s operation. In addition, safety features like fuses and overload protectors are essential to prevent electrical malfunctions, maintaining both efficiency and safety.

How a Compact Cooling Unit Works Internally

At the heart of a small refrigeration system lies a complex internal process that keeps the temperature low and ensures efficiency. The entire cycle involves various stages, each essential to maintaining a constant internal environment. By manipulating refrigerant flow, pressure, and temperature, these systems create the ideal conditions for cooling. Understanding how these processes unfold within the unit can help with troubleshooting and optimizing performance.

The Refrigeration Cycle Explained

The refrigeration process begins when the compressor pumps refrigerant gas into the condenser. As the gas travels through the condenser coils, it cools and condenses into a liquid. This high-pressure liquid then flows through an expansion valve, where it experiences a sudden drop in pressure and temperature. The refrigerant then enters the evaporator coils, where it absorbs heat from the surroundings, causing the liquid to evaporate and re-enter the compressor. This cycle repeats, maintaining a consistent cooling effect.

Thermal Management and Temperature Regulation

Temperature control within a cooling unit is facilitated by the internal thermostat. This component monitors the internal environment and activates the compressor when the temperature rises above the set level. Once the temperature drops, the thermostat signals the compressor to stop, preventing overcooling and ensuring energy efficiency. This delicate balance between cooling cycles is key to maintaining the desired temperature while conserving power.

Identifying Issues Through Component Breakdown

Understanding the inner workings of a cooling unit is essential for diagnosing malfunctions and addressing potential problems. A breakdown of each element in the system allows for a clearer view of where issues might arise. By analyzing the relationship between the various components, it becomes easier to pinpoint the source of common faults, whether they involve temperature control, power failure, or poor efficiency.

One of the most effective ways to detect problems is by examining the functionality of each part in the system. Issues such as a malfunctioning compressor, clogged condenser, or faulty thermostat can be identified through systematic inspection. Knowing where each component fits within the overall operation helps in isolating the specific area requiring attention, making repairs faster and more accurate.