Maintaining a garden tool in optimal condition requires a clear understanding of its individual elements. Knowing how each part functions and fits together ensures proper use and efficient repair when necessary. This knowledge empowers users to address issues independently and enhance the longevity of the equipment.

By reviewing a comprehensive breakdown of the essential elements, owners can easily identify worn or damaged pieces and replace them with minimal effort. It’s crucial to recognize these components to ensure smooth operation and prevent unnecessary wear or malfunction. Regular upkeep also contributes to the overall performance of your tool, keeping it running like new.

Efficient repair relies heavily on the ability to recognize specific components and understand their roles in the broader mechanism. This approach simplifies troubleshooting and helps you make informed decisions about what needs attention, from minor adjustments to complete replacements.

Understanding Trimmer Component Breakdown

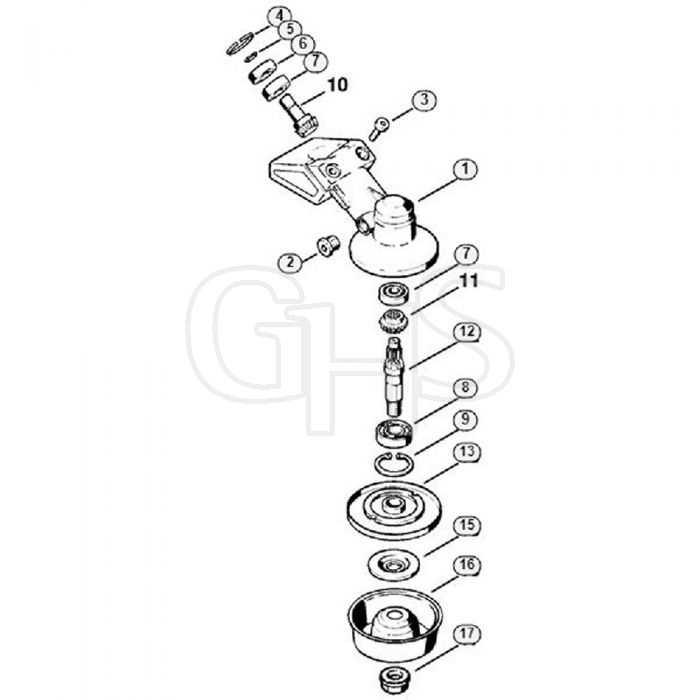

When dealing with a complex garden tool, it’s essential to comprehend how each individual element contributes to its overall function. A visual breakdown or schematic representation can help users easily locate and identify various sections, facilitating smoother repairs and maintenance. This understanding is crucial for ensuring that each part works harmoniously, reducing the chances of malfunctions.

How to Navigate the Schematic

The schematic representation divides the tool into different areas, such as the engine, cutting mechanism, and handle assembly. Each segment is clearly marked, allowing users to pinpoint exactly which components need attention. By becoming familiar with the layout, you can avoid unnecessary disassembly and target only the parts requiring repair or replacement.

Identifying Commonly Replaced Components

Certain components are more likely to wear out over time due to frequent use. These include the cutting head, fuel system elements, and vibration dampers. Recognizing these parts in the schematic allows for a proactive approach to maintenance, helping to keep the tool running efficiently. Early identification of damaged parts ensures timely replacements, minimizing downtime and improving performance.

How to Identify Trimmer Components

To effectively maintain or repair your garden tool, it’s essential to accurately identify the different components within the machine. This allows users to troubleshoot and replace damaged parts quickly. Knowing the specific function of each piece helps avoid unnecessary disassembly and ensures that only the necessary components are addressed.

Begin by familiarizing yourself with the major sections of the tool, such as the engine, fuel system, and cutting mechanism. These are typically the areas most prone to wear. Once you understand where each part is located, the next step is to recognize the unique features that distinguish each component, such as size, shape, or position within the machine.

Some components, like the spark plug, air filter, and drive shaft, are more easily identified due to their distinct shapes. Others, such as small seals or gaskets, may require more attention to detail. Knowing how each piece interacts with the overall mechanism will help when it’s time for maintenance or replacement.

Common Issues and Components Replacement Tips

Over time, regular use of garden tools can lead to wear and tear on various components. Identifying these issues early on allows for efficient maintenance and prolongs the life of the equipment. By understanding common malfunctions and knowing how to replace specific elements, users can avoid costly repairs and keep their tools in top condition.

One of the most common issues is a worn-out cutting head, which can become dull or damaged after prolonged use. Replacing the cutting mechanism promptly is essential to maintain performance. Similarly, fuel lines and filters may degrade, resulting in difficulty starting the engine. These components should be replaced regularly to ensure smooth operation.

Tip: Always use original or high-quality replacement components to ensure compatibility and optimal function. Regularly check for signs of wear, especially in areas exposed to friction or heat, such as the drive shaft and spark plug. By staying ahead of maintenance needs, you’ll reduce the likelihood of unexpected breakdowns.