When working with lawn equipment, having a clear understanding of its individual components is essential for efficient maintenance and repairs. Knowing how each piece functions together can significantly improve the performance and longevity of your machine. This section will guide you through the essential elements of a trimmer and provide you with a comprehensive approach to managing and fixing it.

By carefully studying the assembly, users can identify which components require attention or replacement. A well-structured breakdown allows for accurate diagnosis and troubleshooting, ensuring your device operates at its best. Whether you’re a seasoned professional or a first-time user, mastering this knowledge is key to keeping your equipment in optimal condition.

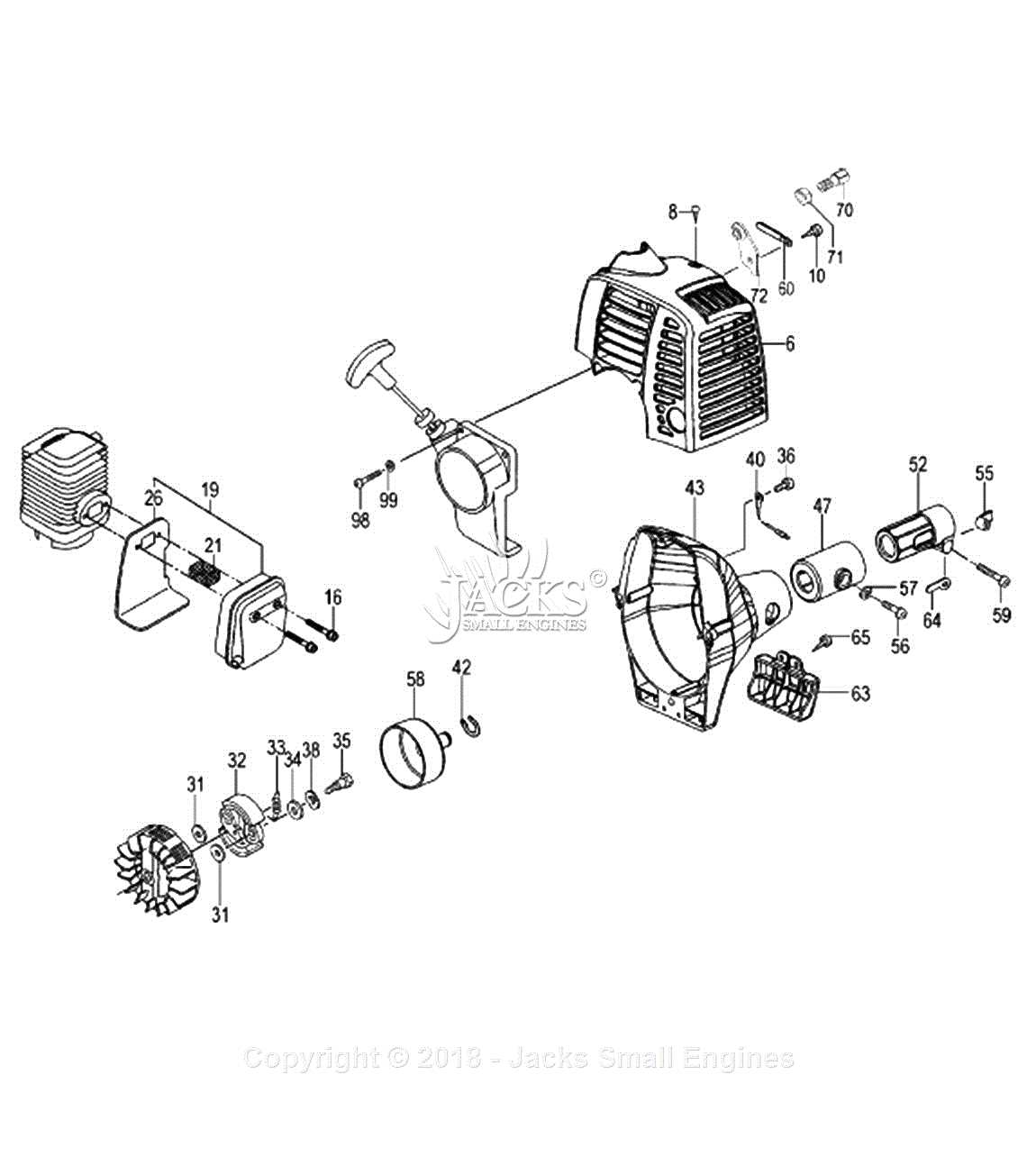

Understanding Trimmer Components

A deep understanding of the various elements that make up a lawn tool is crucial for both troubleshooting and efficient operation. Every piece plays a specific role in ensuring the machine works smoothly. Whether it’s the engine, the cutting mechanism, or the control handles, each component must function harmoniously to achieve optimal results.

Identifying the core sections of the equipment helps in recognizing potential wear and tear. Regular inspection of key parts can save time and money by preventing larger issues down the line. Familiarity with these sections also aids in the quick identification of faulty components that need replacing, keeping your device running at peak performance.

Some essential parts include the power unit, transmission system, and various attachments. Understanding their layout and function helps users make informed decisions about repairs or upgrades. By mastering the components of the tool, you ensure a more productive and efficient experience each time you use it.

How to Identify Components in the Breakdown

To efficiently maintain and repair your lawn tool, it’s essential to know how to properly identify its various components. A visual representation of these parts helps you distinguish between the different sections, ensuring you can easily pinpoint any worn or damaged components. Understanding the labeling system and the layout of these visuals is key for successful maintenance.

Start by familiarizing yourself with the general arrangement of the tool. Each component is typically numbered or labeled for easy reference, making it easier to locate specific pieces. Pay close attention to how each section is connected, as this will guide you in recognizing whether the issue lies in the motor, cutting system, or another part.

By studying these breakdowns closely, you will become proficient in identifying which components need repair or replacement. This process also aids in understanding how each part interacts with the others, ensuring proper functionality once the issue is resolved.

Common Components Replacement Guide

Regular maintenance of your lawn equipment involves replacing worn or damaged components to keep the machine running efficiently. Some sections are more prone to wear due to constant use, and knowing when to replace them can extend the lifespan of the tool. This guide covers the most commonly replaced parts and offers tips for easy replacement.

Engine and Drive Mechanism

The engine and its drive mechanism are crucial for the power and movement of the tool. Over time, parts such as spark plugs, fuel filters, and drive belts may degrade or wear out. Regularly checking these components and replacing them when necessary can prevent performance issues and ensure a smooth operation.

Cutting System and Attachments

The cutting system, including the blades or strings, is often subject to wear due to frequent use. It’s important to inspect these parts regularly for signs of damage. Replacing blades or trimmer heads when they become dull or cracked will keep the tool functioning properly and help you achieve the best cutting results.