Every piece of outdoor equipment has a unique set of components that work together to ensure smooth operation. Understanding how these elements are structured and connected is essential for effective maintenance and repair. This guide aims to provide clarity on the various parts and their functions, helping users keep their equipment in top condition.

Proper knowledge of each individual element will not only assist in troubleshooting common issues but also in performing regular upkeep tasks. By referencing visual aids that showcase the specific arrangement of components, you can easily identify areas needing attention and ensure that everything is functioning as intended.

With a clear understanding of the tool’s internal and external parts, users can confidently engage in the necessary repairs or replacements, extending the life of their equipment. This comprehensive breakdown serves as a valuable resource for anyone looking to enhance their maintenance skills and keep their tool operating at its best.

Understanding the Tool’s Components

Every piece of equipment consists of several essential elements that work together to provide reliable performance. Understanding how these components interact is crucial for proper maintenance and functionality. In this section, we will explore the key components that make up the tool, helping you identify and troubleshoot any issues more effectively.

Main Elements of the Equipment

The core structure of the tool includes a combination of mechanical and electrical components, each playing a specific role in its operation. These elements are designed to ensure smooth power transfer and efficient performance. Familiarity with their functions will help you recognize when maintenance is required and which part needs attention.

Critical Components to Focus On

Among the most important elements are those responsible for the power system, control mechanisms, and safety features. Understanding the role of each part ensures that you can maintain the tool properly and avoid unnecessary damage. Regular checks and timely replacements of worn-out components will contribute to the longevity of the equipment.

Key Parts for Maintenance and Repair

Regular maintenance is essential for keeping your outdoor equipment running smoothly. Some components require more attention than others to ensure optimal performance. Identifying and focusing on these key elements will help you extend the lifespan of your tool and prevent common malfunctions.

The following list highlights the most important parts to monitor and maintain:

- Fuel System: Regularly clean and replace filters to avoid clogging and ensure proper fuel flow.

- Ignition System: Inspect the spark plug and wires for signs of wear to maintain smooth starting and operation.

- Air Intake: Ensure the air filter is clean to prevent dust and debris from entering the engine, affecting performance.

- Blades and Cutting Mechanisms: Check for any damage or dullness that could reduce cutting efficiency.

- Throttle and Controls: Make sure the throttle mechanism is responsive and free from obstructions for accurate control.

By regularly inspecting and maintaining these vital components, you can ensure that your equipment remains reliable and performs at its best when needed most.

How to Read the Components Illustration

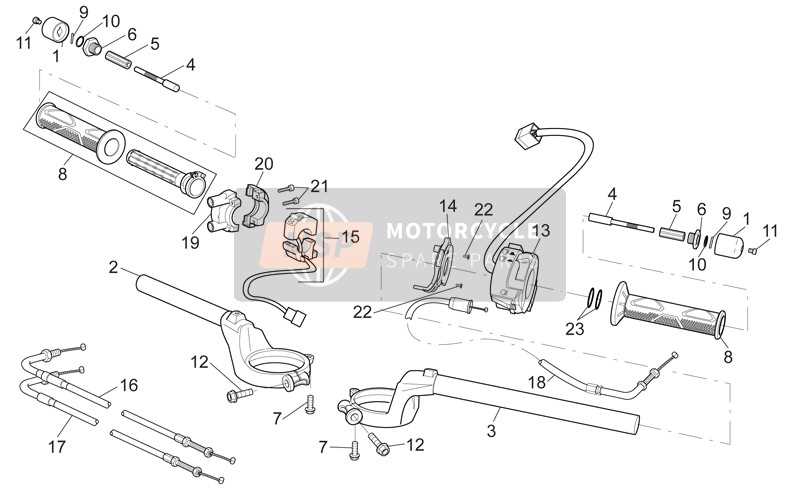

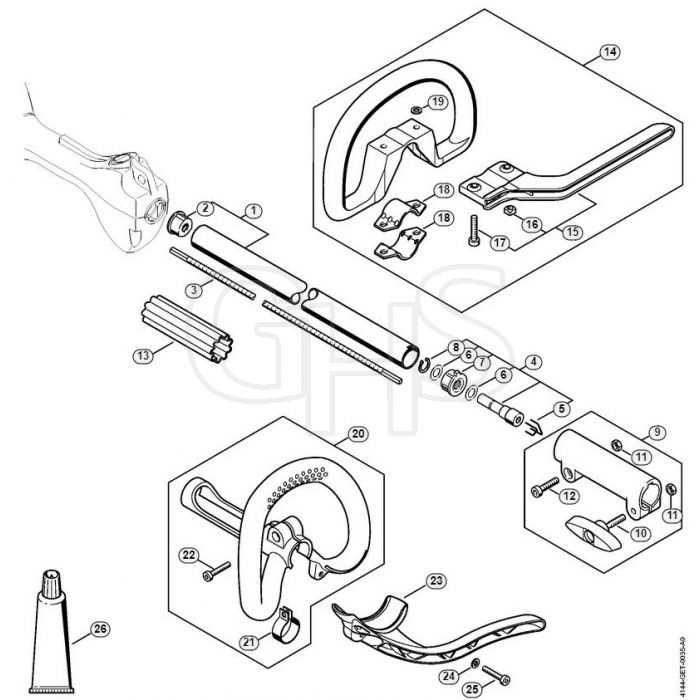

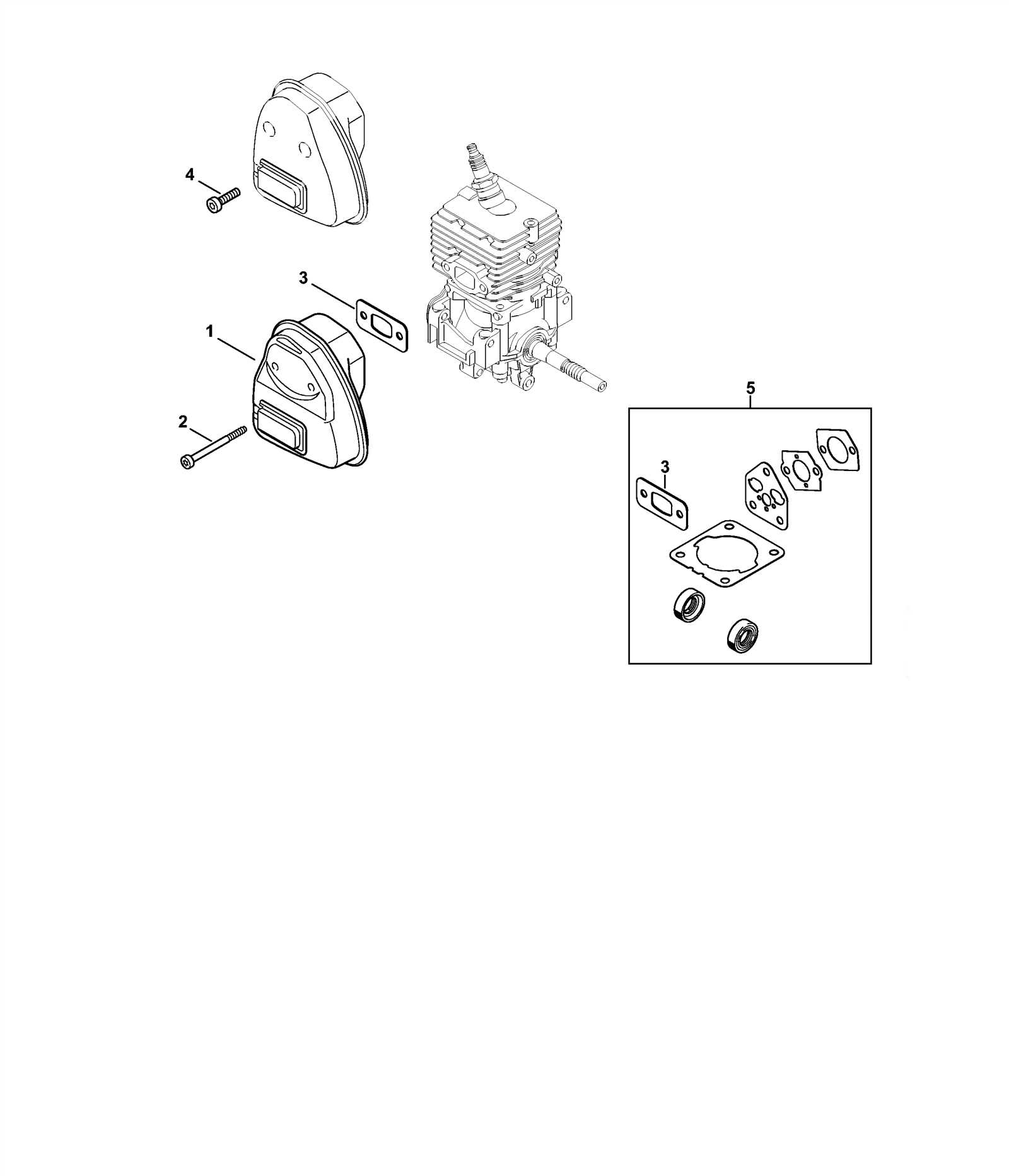

Understanding how to interpret a visual representation of your equipment’s internal structure is crucial for performing maintenance and repairs effectively. These illustrations provide a clear and detailed view of each element, helping you identify the exact location and function of each part. Knowing how to read these visuals ensures that you can locate components easily and accurately address any issues that arise.

First, focus on the labels and numbering system that accompany the illustration. Each component is typically labeled with a unique identifier that corresponds to a reference number, making it easier to cross-check with manuals or catalogs. This numbering allows for precise identification and ordering of replacement parts.

Next, pay attention to the color coding or shading that might be used in the illustration. Often, different colors are applied to various sections to distinguish between major assemblies, electrical components, or mechanical parts. This helps clarify the relationships between different elements and how they work together.

Finally, familiarize yourself with the viewpoints and angles presented in the visual. Some illustrations provide a side view, while others may show top or bottom perspectives. Understanding these different viewpoints ensures that you are looking at the component layout from the correct angle, giving you a comprehensive understanding of how everything fits together.