When working with any mechanical tool, knowing the internal structure and its functioning parts is crucial for maintenance and troubleshooting. Being able to recognize each individual element can significantly improve your efficiency during repairs and routine checks. This guide will provide an overview of how to approach and comprehend the various components of a specific model, ensuring you are well-equipped for any task that comes your way.

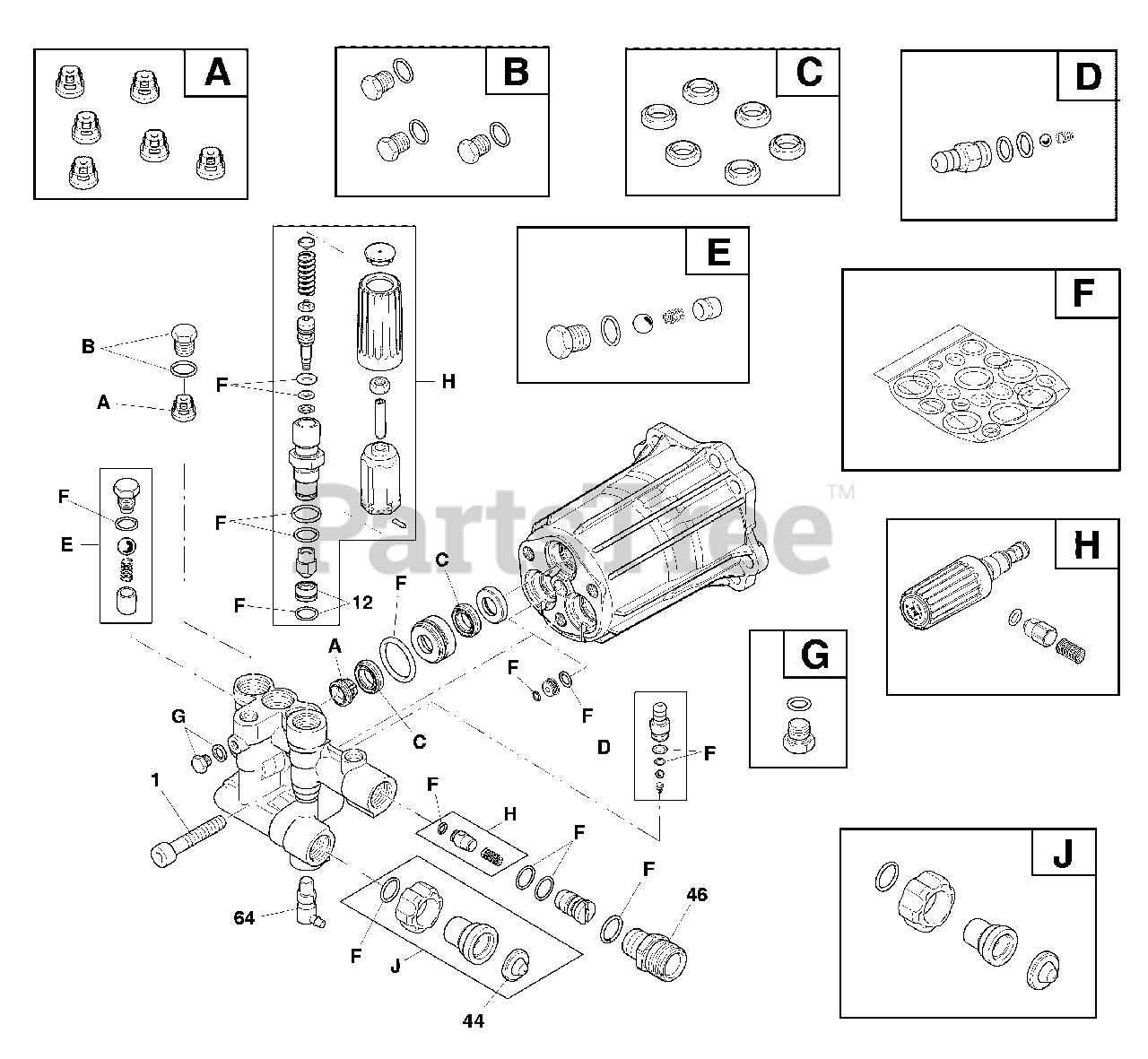

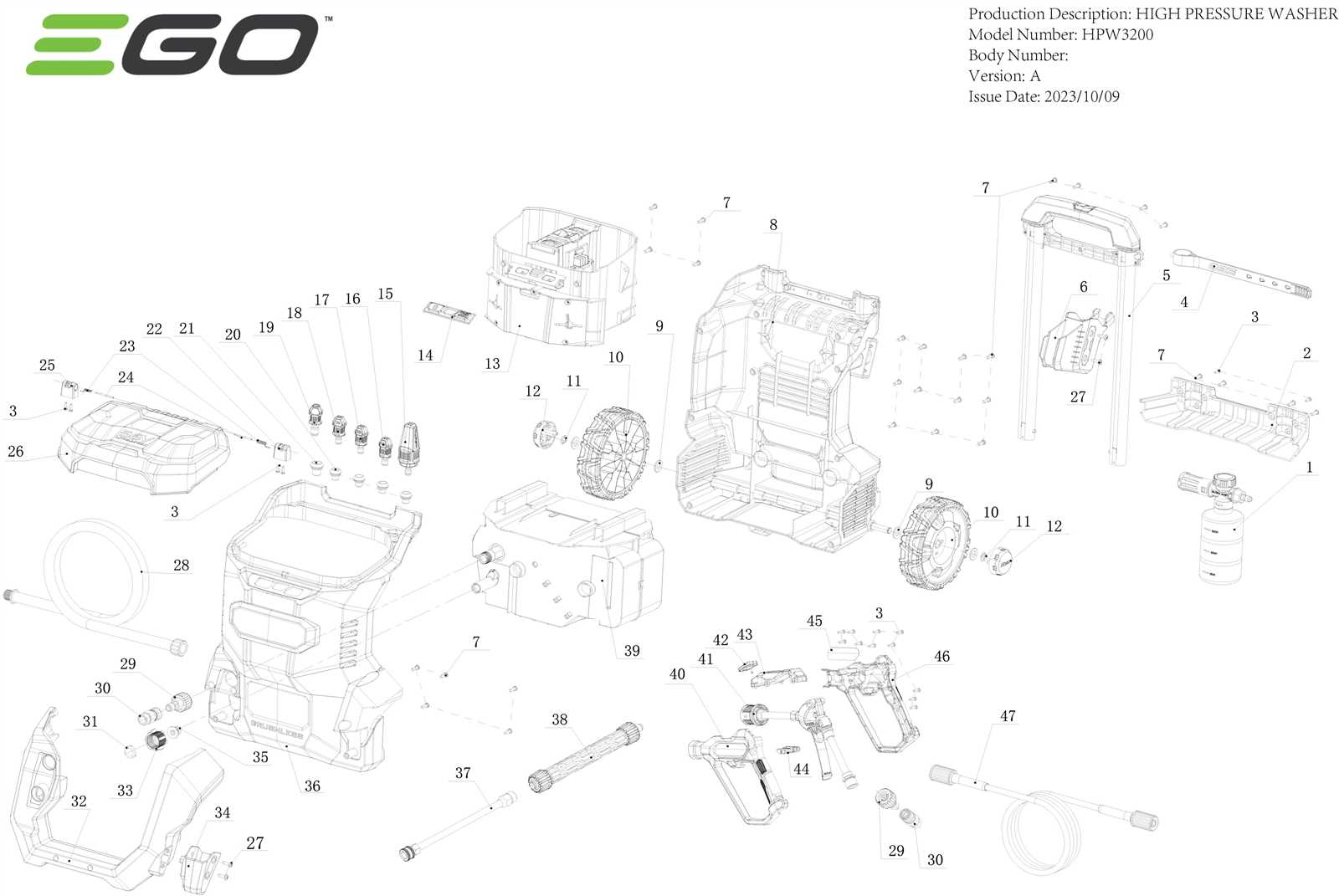

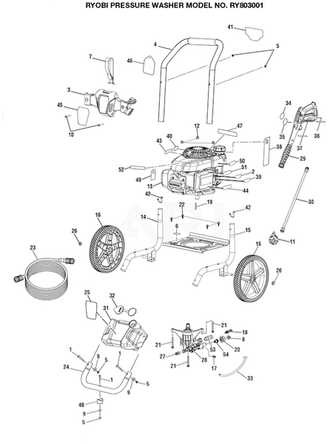

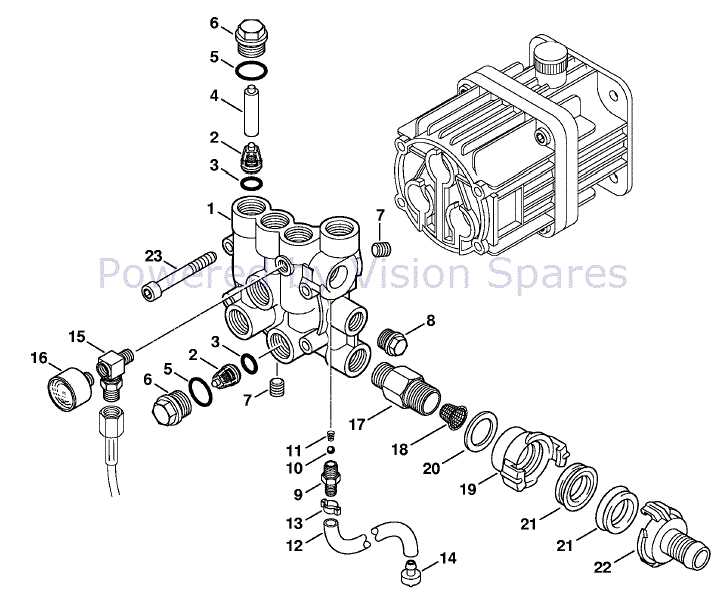

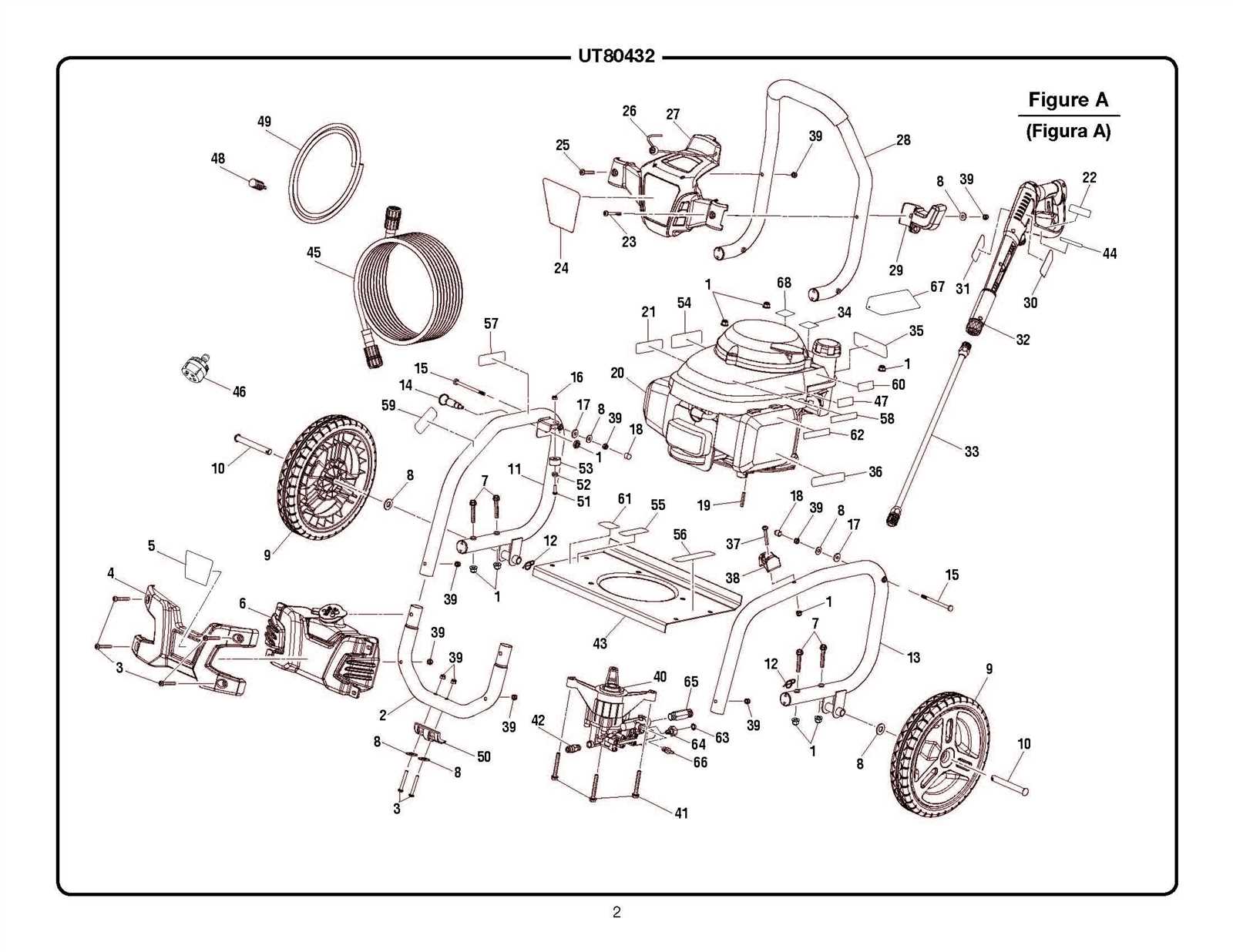

Effective use of diagrams can make the process of identifying individual elements easier, especially when you encounter issues or need to replace specific components. Visual aids help break down complex systems into understandable parts, giving you a clearer view of how everything fits together.

Having a comprehensive understanding of these elements not only aids in resolving technical issues but also contributes to prolonging the life of the equipment. Regular inspection and awareness of the internal mechanisms will keep your tool functioning optimally for longer periods.

Understanding Honda Pressure Washer Components

Every machine operates through a series of interconnected elements, each with a distinct function that contributes to the overall efficiency. Familiarity with these key components allows for quicker troubleshooting, maintenance, and part replacement when necessary. Recognizing how each part interacts within the system can provide deeper insight into the mechanics behind the equipment’s performance.

The essential components of this type of equipment include the motor, pump, hoses, and nozzles. Each of these parts plays a vital role in how the machine operates, whether it is generating force or regulating flow. Understanding their placement and function is crucial for keeping the device running smoothly and ensuring that issues can be resolved efficiently.

Regular inspections and understanding the function of these elements can prevent malfunctions and ensure that the machine is performing at its peak. Taking the time to familiarize yourself with the system’s layout helps you spot potential problems before they affect overall performance.

Identifying Key Parts in Honda Pressure Washers

Understanding the core components of your equipment is essential for effective troubleshooting and maintenance. By identifying the critical elements, you can ensure the system operates smoothly and efficiently. Each part serves a specific purpose, and recognizing its function helps in identifying problems early and carrying out timely repairs.

The engine is one of the most vital components, responsible for powering the entire unit. It drives the pump, which is crucial for generating the necessary force. Other key components include the nozzles, which control water flow, and the hose, which directs the flow to the intended area. Additionally, seals and valves are critical for maintaining the correct pressure levels and ensuring the system is leak-free.

Familiarity with these components is essential for anyone working with this equipment. Knowing where to find them, how they connect, and their individual roles will make maintenance tasks much more manageable and help in extending the lifespan of your tool.

How to Use the Parts Diagram Effectively

Visual aids are invaluable when it comes to understanding the internal structure of your equipment. A detailed illustration helps you pinpoint specific components and understand their relationships within the system. Using such a reference correctly can save time and enhance the accuracy of your repairs and maintenance tasks.

Step-by-Step Identification

Begin by carefully reviewing the illustration, ensuring you recognize each component. Pay close attention to the labels, as they will guide you to the part you need. Once you have identified the relevant parts, cross-reference them with your equipment to verify their placement. This approach will help you navigate through more complex systems with ease.

Using the Diagram for Repairs

When tackling a malfunction, the visual guide can act as a roadmap. Follow the diagram to identify which components might be damaged or need replacement. This not only speeds up the process but also ensures that no part is overlooked, making the repair process more efficient and thorough.