When working with your lawnmower, knowing the layout and structure of its essential components is key to ensuring smooth maintenance and repairs. Familiarity with each part helps in troubleshooting and enhances the longevity of your equipment. This guide offers a detailed breakdown of how all the essential elements are connected, making it easier to diagnose issues and carry out replacements efficiently.

Each lawnmower model has its unique design and assembly, but there are common parts that most share. Identifying and understanding their function is crucial for anyone looking to perform maintenance tasks or upgrades. In this article, we’ll provide you with a comprehensive overview of the key sections and their interactions to help you with your lawnmower care.

Understanding the Lawn Mower Components

Every lawnmower is built with various essential elements that work together to ensure efficient operation. These components, while varied in their function, all play a vital role in the performance of the machine. Gaining an understanding of these elements is important for anyone looking to maintain or repair their equipment. By knowing where each part is located and how it fits into the overall system, you can make more informed decisions when it comes to troubleshooting or replacement.

Key Elements of the Mower’s System

Among the most critical components are the engine, cutting blade, and drive system. The engine powers the mower, while the cutting blade does the primary work of trimming the grass. The drive system allows for movement, making the mower easier to operate. Each of these elements must work in harmony for the mower to function correctly.

Maintenance and Care

Understanding the design and function of these components also makes it easier to keep your lawnmower in top condition. Regular inspection and maintenance of each part can prevent major issues. For example, checking the air filter, spark plug, and fuel system ensures that the engine remains efficient. Keeping the blades sharp and free from debris helps maintain cutting performance.

Identifying Key Parts for Easy Repair

Recognizing the key elements of your lawnmower can greatly simplify the repair process. Knowing where each part is located and understanding its role makes troubleshooting much faster and more efficient. This section will help you identify the most important components that are often involved in common issues. By familiarizing yourself with these parts, you can quickly determine what needs attention and reduce the time spent on repairs.

Critical Components to Examine

Start with the engine and its surrounding elements. The engine is the heart of the machine, so checking the fuel system, spark plug, and air filter should always be your first step. A malfunction in any of these areas can lead to poor performance or failure to start. Next, inspect the cutting mechanism, especially the blade and its connection to the drive system. Any misalignment or dullness here can result in uneven cutting.

Common Issues and Fixes

When problems arise, the most common issues often involve the engine, cutting blades, or the drive system. If the mower fails to start, a clogged fuel line or dirty spark plug is typically the cause. For cutting problems, check the blade for sharpness and any buildup of debris. If the mower isn’t moving correctly, examine the drive belt or wheels for wear. Identifying these parts quickly can lead to easier and faster fixes.

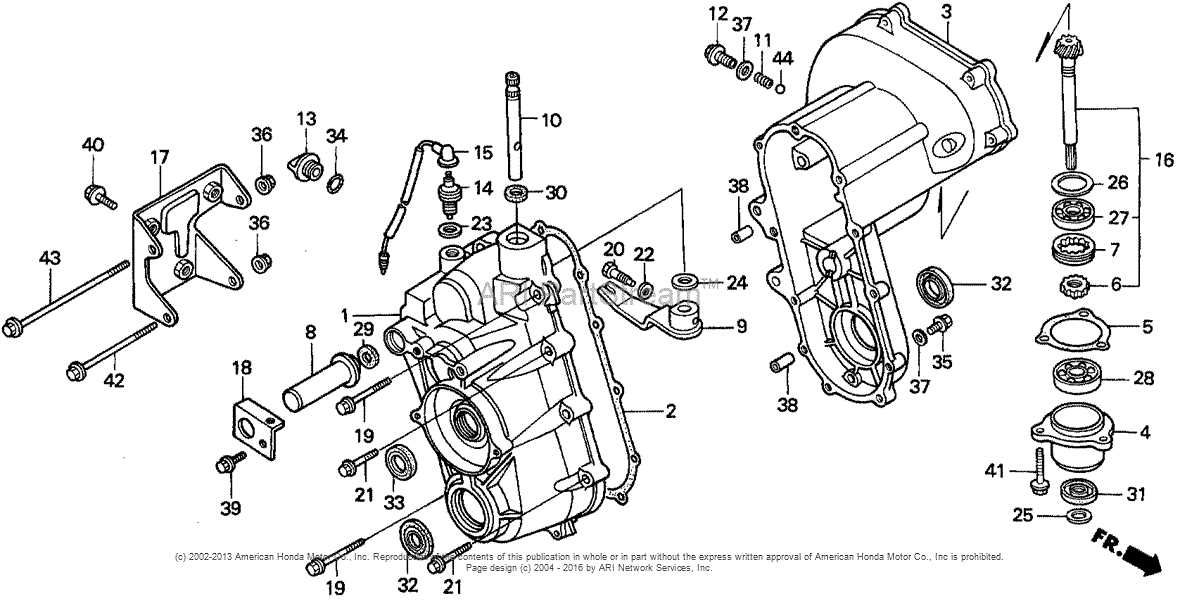

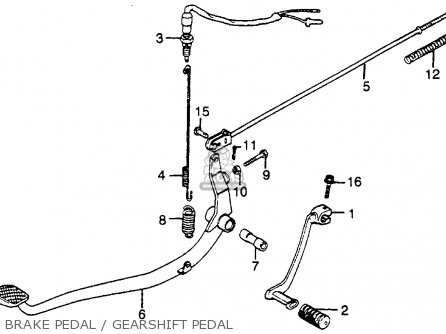

How to Use the Lawn Mower Blueprint

Understanding how to navigate a visual representation of your lawnmower’s components can significantly ease the process of maintenance and repair. A well-detailed schematic provides an overview of the machine’s structure, highlighting the position and connection of each part. Using this blueprint helps you locate components quickly, making it easier to identify problems and perform repairs or replacements with accuracy.

To begin, examine the overall layout and identify major sections like the engine, cutting system, and drive mechanism. Each part will be labeled, allowing you to pinpoint where each element fits into the larger system. By following the arrows or labels, you can understand how different parts interact with each other. This understanding is crucial when troubleshooting or making adjustments.

When working with the schematic, always ensure that you’re following the correct order and orientation of components. This way, you can avoid mistakes when assembling or disassembling parts. Additionally, refer to the diagram whenever you’re uncertain about the function of a specific part or need to verify its correct placement in the machine.