Every machine is made up of numerous essential elements that work together to ensure its smooth operation. For any sprayer, knowing how these components fit together is crucial for proper maintenance and efficient performance. Having a clear understanding of these key pieces can help you identify issues quickly and prevent further damage.

Familiarizing yourself with the various parts of your device will enable you to troubleshoot problems effectively. This knowledge is essential whether you’re looking to replace worn-out components or simply perform routine checks to maintain peak functionality.

In this guide, we will walk you through the most important elements of a typical sprayer. Understanding their placement and function will provide you with the tools necessary to keep your equipment running at its best. Proper upkeep will ensure that your sprayer remains a reliable tool for your projects, reducing downtime and repair costs.

Understanding Graco X7 Sprayer Parts

Knowing the essential components of your sprayer is vital for ensuring its longevity and optimal performance. Each element has a specific function, working together to deliver consistent results. Gaining insight into the layout and role of these pieces will help you handle maintenance, identify potential issues, and perform necessary repairs more efficiently.

The key components of the machine are designed to handle specific tasks, such as delivering the right amount of pressure or ensuring smooth fluid flow. Regularly inspecting these pieces for wear and tear can help extend the life of your equipment and avoid unexpected malfunctions.

Understanding how each element interacts is important for troubleshooting. Whether you’re dealing with clogs, pressure loss, or mechanical failures, a clear grasp of the individual parts can help pinpoint the issue faster. This knowledge allows you to perform timely fixes, ensuring that your sprayer remains functional and ready for use at all times.

How to Read the Graco X7 Diagram

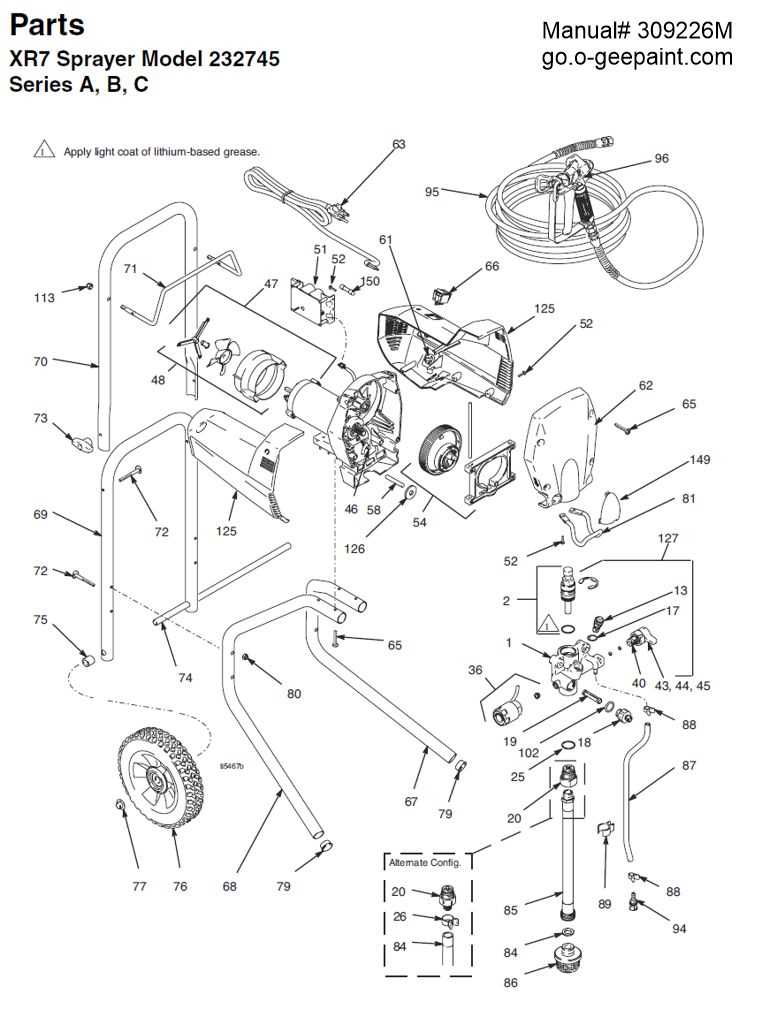

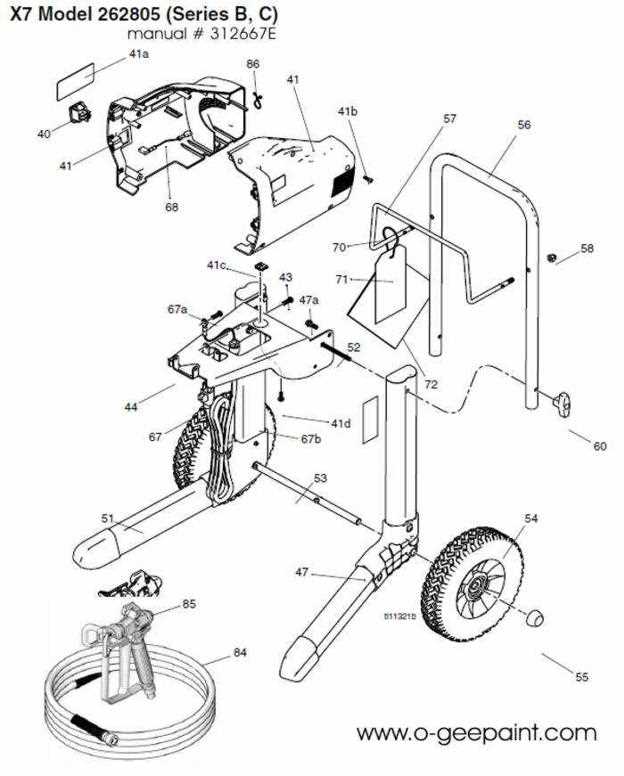

Interpreting the layout of a machine’s components is crucial for effective repairs and maintenance. A well-detailed illustration can serve as a guide, helping you identify the key elements, their positions, and how they interact. Understanding this visual representation ensures that you can locate parts quickly and efficiently, making repairs more straightforward.

Start by examining the labels and references included in the image. Each section or component is usually marked with a unique identifier, which corresponds to the item’s description in the accompanying list. This helps to cross-reference the visual with the detailed explanation of each piece.

Additionally, pay attention to the orientation and connections shown. These diagrams often provide valuable insight into how parts are connected and how fluid or air should move through the system. A clear understanding of this flow can help in troubleshooting performance issues and prevent assembly mistakes.

Common Issues with Graco X7 Components

Despite their durability, sprayers can experience issues over time due to wear, improper maintenance, or external factors. Understanding the most common problems can help you address them quickly and prevent further damage. Familiarizing yourself with these issues allows you to perform timely repairs and ensure consistent performance.

Some frequent problems include:

- Clogs in the fluid system, often caused by dried paint or debris, leading to reduced flow and performance.

- Loss of pressure, which can occur due to air leaks or worn seals, affecting the sprayer’s ability to apply the material evenly.

- Faulty motor or pump, which may fail due to overuse or lack of lubrication, resulting in operational stoppages.

- Unstable spray pattern, often linked to issues with the nozzle or improper setup.

By addressing these problems early, you can extend the life of your equipment and keep it functioning at its best. Regular cleaning, maintenance, and prompt repairs are key to minimizing downtime and maximizing efficiency.